|

MANMADE BOARDS V. Ryan © 2001 - 2008

|

|

|

These are boards that are made in factories from materials such as wood chippings or dust. The sheets are available in standard sizes 2440mm by 1220mm and range from 1.5mm to 25mm thick. |

|

| PDF FILE - CLICK HERE FOR EXERCISE BASED ON INFORMATION BELOW | |

|

|

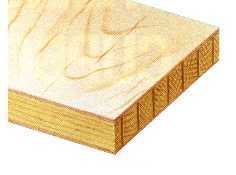

BLOCKBOARD - This is built up with a core of softwood strips bonded together with adhesive and covered with a sheet of plywood on either side. Used as a building material and for furniture manufacture including fitted kitchens / bedrooms. |

|

|

CHIPBOARD - This is made up of small chips of wood bonded together with resin and formed into sheets by compression. It is not as strong as plywood and block board but it is not expensive. Chipboard is often covered with a plastic laminate or wood veneer and used in furniture. |

|

HARDBOARD - This is made from wood fibres

that have been pulped. The pulp is put under pressure until the fibres bond

to produce a tough board that is smooth on one side and rough on the other.

It is not as strong as the other boards. |

|

MEDIUM DENSITY FIBRE BOARD (MDF) - A quality board, relatively cheap. This board is composed of fine wood dust and resin pressed into a board. This material can be worked, shaped and machined easily. Paint can be applied to it without the need for an undercoat or primer. Used in the building and furniture trades. |

|

PLYWOOD - This is made from veneers (plies)

of timber with each grain layer being at right angles to each other and

bonded together by resin and pressure. A number of grades are available,

designed to suit a variety of situations. |

|

|

|