PUBLIC SEATING - DEVELOPMENT OF IDEA FOUR AND FIVE

V. Ryan © 2017

|

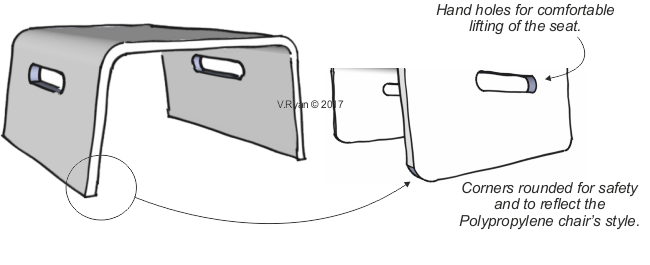

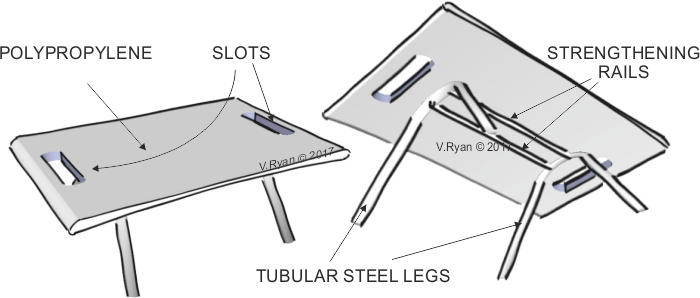

| DEVELOPMENT OF IDEA FOUR |

| Polypropylene, injection moulded seat. Modernist in style and reflecting the Polyprop chair. |

|

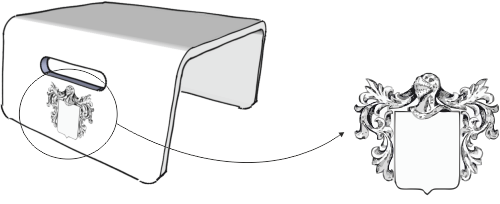

| Personalised crest, suitable for schools, companies and organisations. Injection moulding in large numbers, makes this feature economic. The crest is all part of the mould. |

|

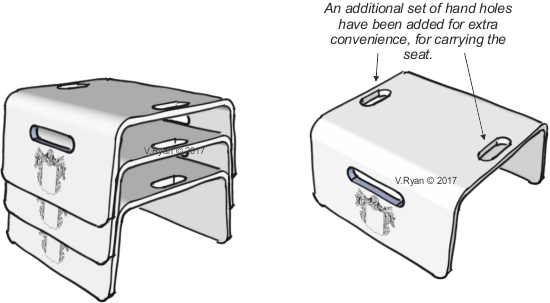

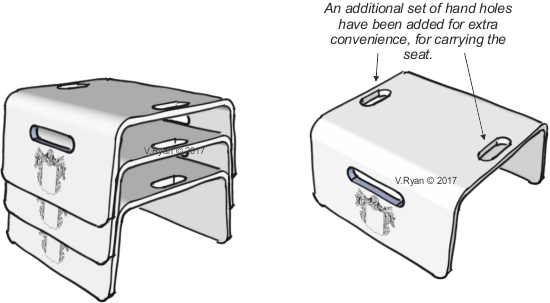

| The seat stacks as high as is convenient. The stacks are lightweight and can be moved. |

|

|

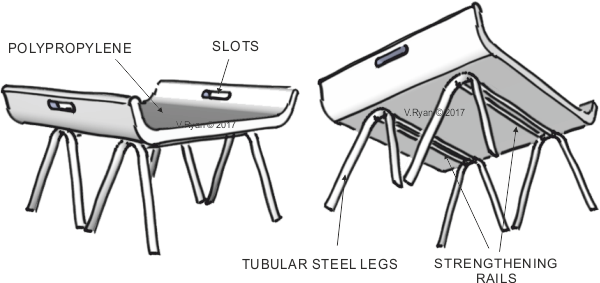

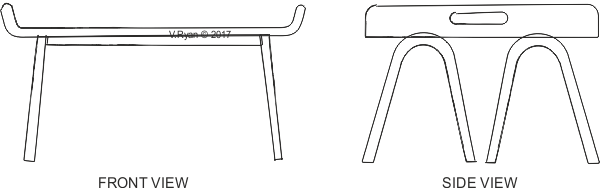

| DEVELOPMENT OF IDEA FIVE |

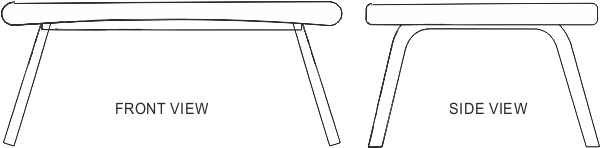

| This seat has a polypropylene top and tubular steel legs, the same materials as the Polyprop Chair. It is lightweight and has slots for handles. It can be moved with ease. The seat is stable and difficult to knock over. The polypropylene is easy to wipe clean and is available in a range of colours. |

|

|

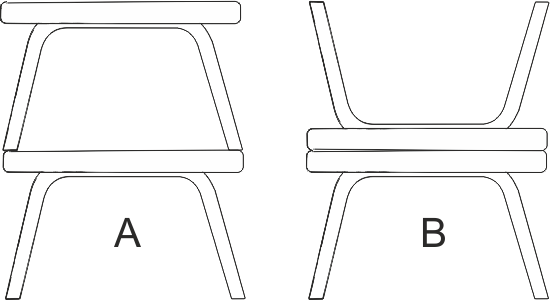

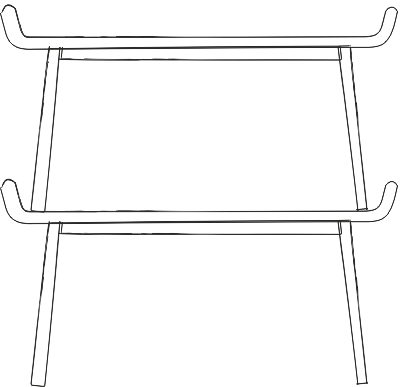

The seat can be stacked in two ways, as seen opposite. Diagram ‘A’ shows the seat stacked in the least stable / safe way. The seat stacked on top would be likely to fall off. Diagram ‘B’ is the most stable method of stacking, although only two seats can be stacked together. |

|

Polypropylene is used to manufacture the seat. The ‘ends’ are curved upwards, which is both a design feature and has two practical applications. The first is that the seat can be lifted easily, as the ‘hand’ slots are ergonomically positioned. The steel legs are in the same style as the Ployprop Chair. The entire seat is lightweight and easy to lift. |

|

|

| The seats can be stacked on top of each other. The curved ends help prevent the ‘top’ seat sliding off sideways. |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |