| CLICK HERE FOR INDEX PAGE | ||

| TOLERANCE CHECKS | ||

| V. Ryan © 2013 | ||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | ||

|

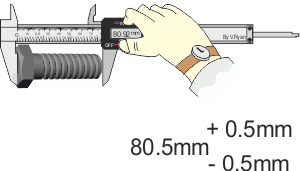

TOLERANCE Checking that a product is manufactured within an upper and lower limit. Example: Thousands of steel bolts are manufactured by a company. Samples are check that they are the correct size. Each bolt must fall within a maximum and minimum length. The tolerance of the bolt is said to be:  |

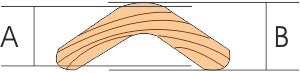

TOLERANCE To ensure the quality of their product, a boomerang manufacturer carries out tolerance checks. When each boomerang is finished, it is checked to ensure that each one is as near to the ‘correct’ size as possible. Each boomerang must fall between two critical measurements for height and length. The height must fall within measurements ‘A’ and ‘B’ and the length within ‘C’ and ‘D’. This is called ‘tolerance’. Any boomerang falling outside either of these sets of measurements is rejected and recycled.  |

|

|

WHY TOLERANCE CHECK PRODUCTS? When a product is mass produced in thousands and hundreds of thousands, samples are regularly checked to ensure that they fall within the tolerance allowed. This ensures: The quality and consistency of the product. Each copy of the product is the same and works exactly the same way. Products that have many parts, will fit together and work in the way that they are supposed to. Products that do not fit with the set tolerances, are rejected and do not reach the customer. |

|

|

| 1. Products and components on a production line often go through ‘tolerance’ checks. With reference to at least one product, explain the term ‘tolerance check’. Draw any sketches on the back of this sheet. 4 marks | ||

| 2. Why are tolerance checks carried out by manufacturers? | ||

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | ||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||