| CLICK HERE FOR INDEX PAGE |

| TURNING A BLANK ON A WOOD WORKING LATHE - 1 |

| V. Ryan © 2012 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

|

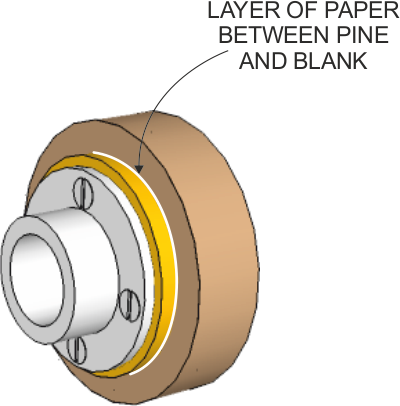

The blank is glued to a piece of ‘softer’ wood such as

pine, with a piece of paper between them. The grain of the pine should be

adjacent to that of the blank. |

|

|

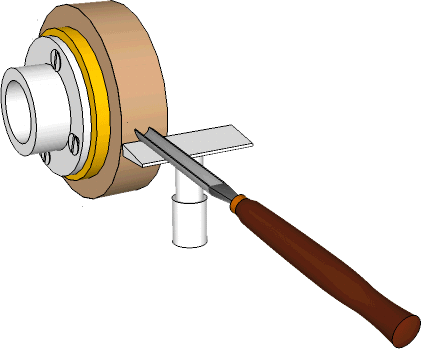

| The blank is not a true cylinder when it

is first placed on the lathe, as it has been cut on a bandsaw. This means

that extra care should be taken when turning. A gouge is used initially, to removed the waste wood, followed by at least one scraper. The type of scraper(s) used to form the external shape is determined by the required profile of the bowl. |

|

| SAMPLE SELECTION OF SCRAPERS USED FOR TURNING THE BOWL |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |