| |

| CLICK HERE FOR INDEX PAGE |

| |

| THE MARKING GAUGE |

| V. Ryan © 2003 - 2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

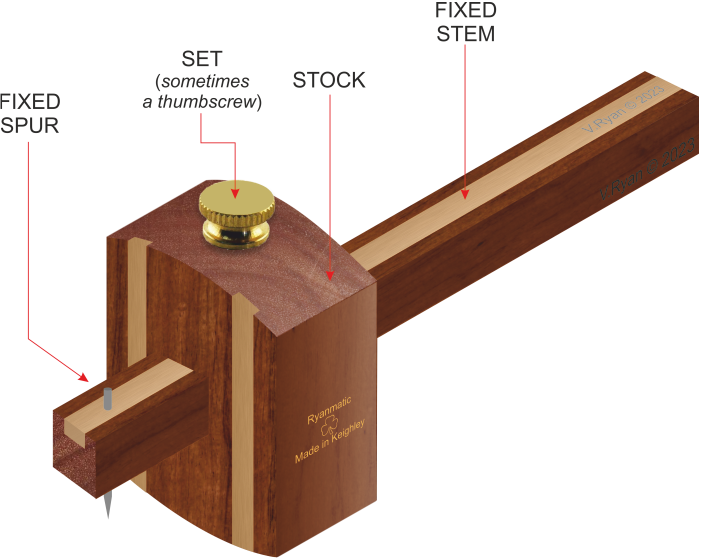

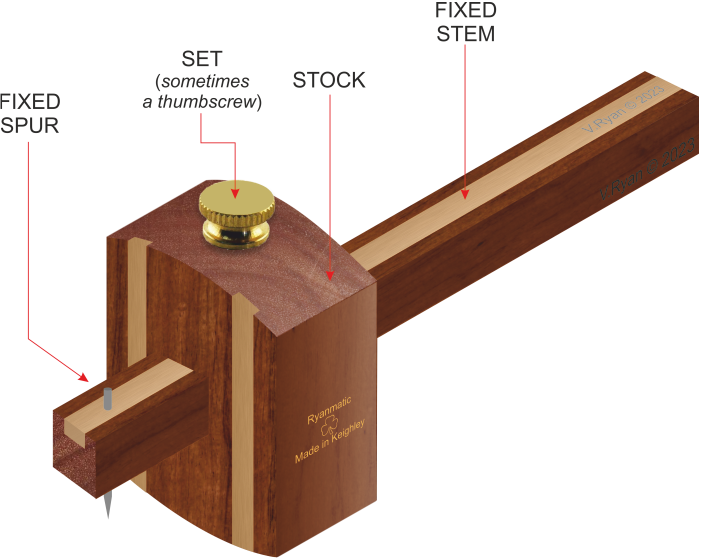

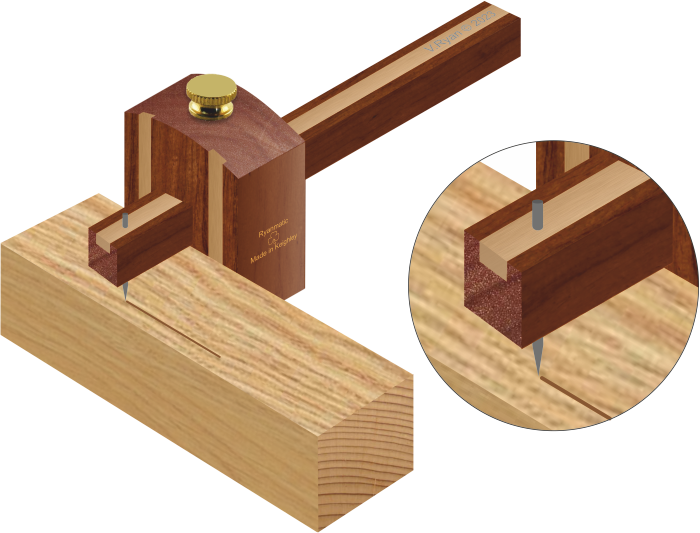

| A marking gauge is used to mark a line parallel to a

straight edge. The stem and stock are made from beech and the thumbscrew

from clear yellow plastic. The better quality gauges have brass inserts

at the front of the stock. These help reduce the wear on the stock as it

is pushed against the surface of the wood - to be marked. The marking

gauge is an extremely important tool for marking parallel lines and

preparing for cutting joints. |

| |

| TWO TYPICAL MARKING GAUGES |

| |

|

| |

| LARGE MORE DETAIL IMAGE OF A QUALITY MARKING GAUGE |

| |

|

| |

|

|

| |

|

| |

| |

The gauge has a sharp point called a spur. This is made from hardened steel and

is the part that ‘scribes’ the line into the surface of the wood. The

distance between the stock and the spur can be adjusted by loosening the

thumbscrew which allows the stock to slide along the stem. The

thumbscrew can then be tightened once the correct distance has been

reached. A ruler is used to set the distance (see diagram opposite).

If the spur is replaced with a small knife it is now called a cutting gauge and is used for cutting lines

into solid wood surfaces in preparation for veneering or inlaying. |

|

|

| |

|

ALTERING THE DISTANCE

BETWEEN THE SPUR AND STOCK |

| |

|

|

| |

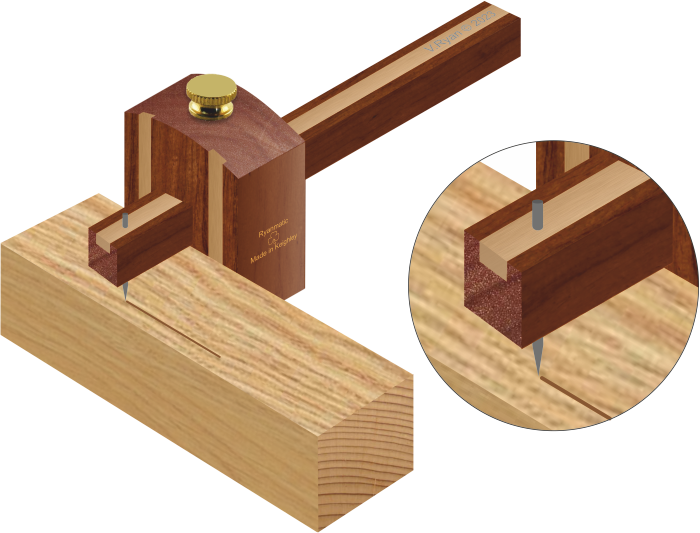

MARKING WITH THE GAUGE

The wood is held firmly to the bench by a G cramp or

bench hook. The stock of the marking gauge is pressed firmly against a

straight edge of the wood and pushed carefully along it. A little

pressure is applied to the spur, too much pressure and the spur digs

into the wood marking an ugly line on the surface.

It is a good idea to lightly scribe a line along the surface first and

then repeat the process two or three times until an accurate scribed

line can be seen. |

| |

|

| |

|

| |

|

|

| |

QUESTIONS

1. Practice

using a marking gauge until you have mastered the process.

2. Draw a marking gauge and label each part. |

| |

| CLICK HERE FOR EQUIPMENT AND ACCESSORIES INDEX |

| |

| |

| |

| |

| |