| CLICK HERE FOR INDEX PAGE | |||||

| THE MICROMETER | |||||

| V. Ryan © 2004 - 2023 | |||||

|

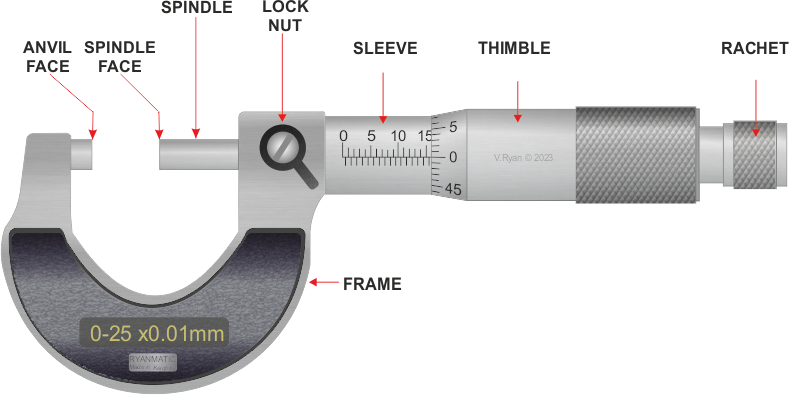

The micrometer is a precision measuring instrument, used by engineers. Each revolution of the rachet moves the spindle face 0.5mm towards the anvil face. The object to be measured is placed between the anvil face and the spindle face. The rachet is turned clockwise until the object is ‘trapped’ between these two surfaces and the rachet makes a ‘clicking’ noise. This means that the rachet cannot be tightened any more and the measurement can be read. |

|||||

|

|

|||||

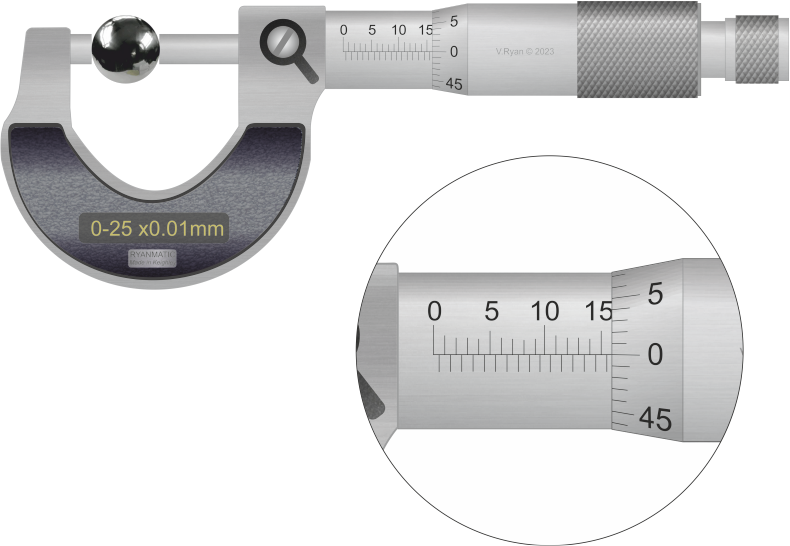

| PHOTO-REALISTIC IMAGE OF THE MICROMETER | |||||

|

|||||

|

|||||

|

EXAMPLE MEASURE READINGS |

|||||

|

Using the first example seen below: 1. Read the scale on the sleeve. The example clearly shows12 mm divisions. 2. Still reading the scale on the sleeve, a further ˝ mm (0.5) measurement can be seen on the bottom half of the scale. The measurement now reads 12.5mm. 3. Finally, the thimble scale shows 16 full divisions (these are hundredths of a mm). The final measurement is 12.5mm + 0.16mm = 12.66 |

|||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

|

|

|

||||

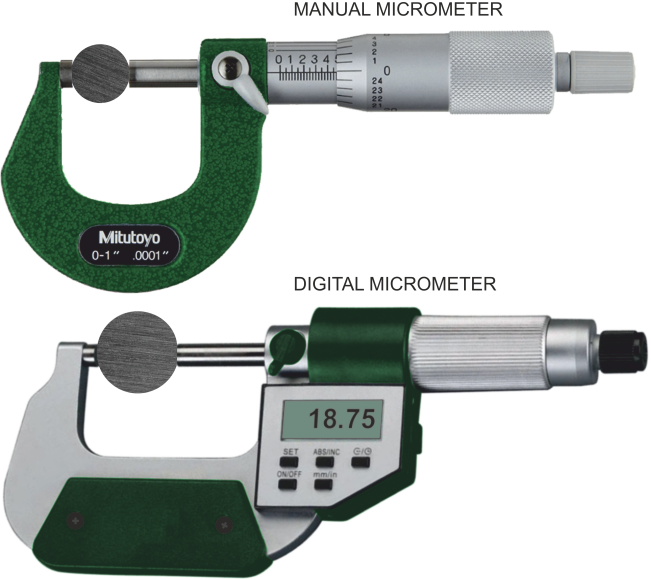

| EXAMPLES OF THE TWO MAIN TYPES OF MICROMETER | |||||

|

|||||

|

|

|||||