| CLICK HERE FOR INDEX PAGE | |

| THE MORTISE CHISEL | |

| V. Ryan © 2003 - 2024 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

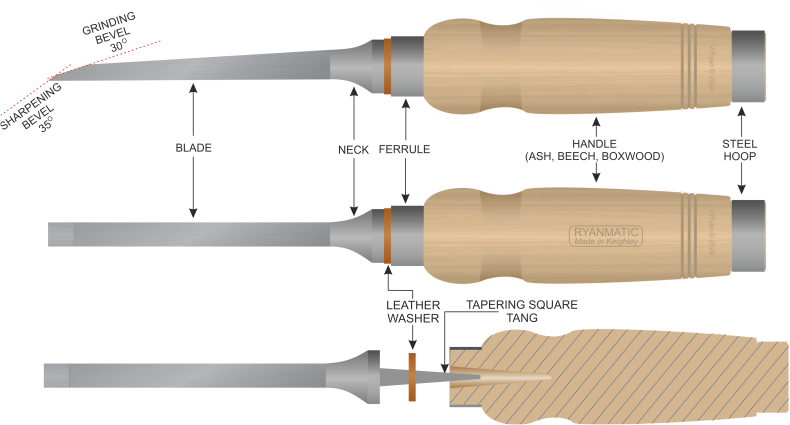

Mortise chisels are used for ‘chopping out’ joints (chiselling away the

waste wood). They are particularly useful for cutting mortise joints as

they are strong enough to withstand heavy blows with a mallet. |

|

|

|

|

|

|

|

HOW THE MORTISE JOINT IS CUT 1. A try square and a marking knife are used mark the lines at the top and bottom of the mortise. |

|

|

2. The stock of the mortise gauge is pressed against the side of the wood. It is then pushed along the wood until the mortise is marked out correctly. |

|

|

3. The mortise chisel is then used to remove the waste material. A mallet provides the blows to the chisel. With great care, an accurate mortise can be cut. |

|

QUESTION: |

|

|

|

|