| CLICK HERE FOR INDEX PAGE | |

| THE CENTRE AND DOT PUNCH | |

| V. Ryan © 2002 - 2021 | |

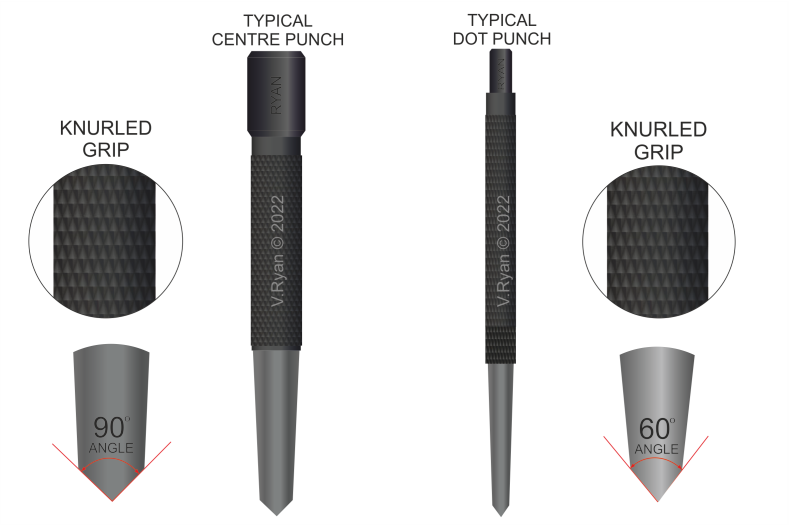

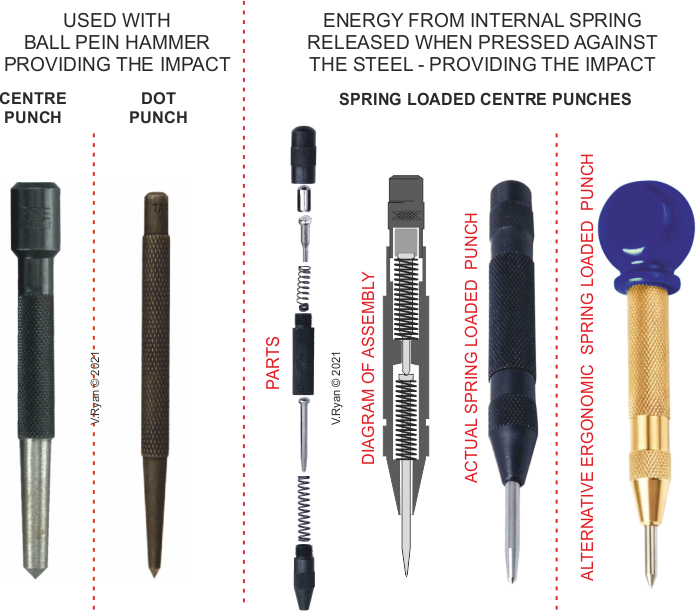

| The centre punch is made from mild steel, with the

point hardened and tempered, so that it withstands impact with the

material it is marking. It is normally used to mark the centre of a hole

to be drilled, either by hand or on the drilling machine. The dot punch is a lighter and thinner version of the centre punch and is used basically for the same job. However, it is more accurate as the dot produced is smaller. |

|

|

|

| Centre punches are often supplied as a set, with the diameter of the ‘tip’ being the size. The set below are 6.5mm, 4.8mm, 4.0mm and 3.2mm. The user selects the punch that most suits the work being carried out. The knurled portion makes it easier to hold the punch when it is being used ,as it can be gripped and prevents the ‘holding’ hand slipping. Centre punches tend to be ground to an angle of 90 degrees. | |

|

|

| Both the centre and dot punches are used in the same way. A ball pein hammer is used to tap the head of the punch and this delivers enough force to the point of the punch to put a small indentation into the surface of the material. | |

|

|

| THE DOT PUNCH | |

| Dot punches are similar to centre punches, although they have a sharper point, ground to 60 degrees (see below). They tend to be used on sheet metals, as they are a ‘lighter’ version of the centre punch. | |

| TWO TYPICAL USES OF A DOT PUNCH AND CENTRE PUNCH | |

| 1. A hole is to be drilled in this material. One possible danger is that the hand drill will slip when drilling first starts. If a centre punch is used to mark the point of drilling, slipping is unlikely to happen. | |

|

|

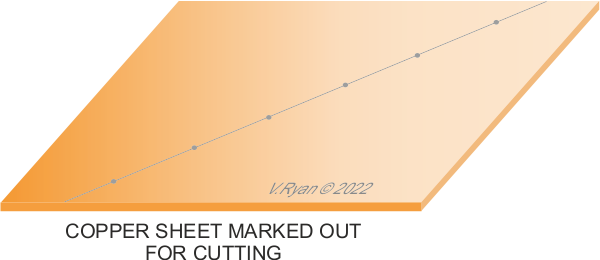

| 2. Sheet metal such as copper, is to be cut along the line. To make it easier to see a dot punch had been used to emphasise the line. | |

|

|

| THE VARIETY OF CENTRE and DOT PUNCHES AVAILABLE | |

|

|

| THE SPRING LOADED PUNCH | |

As pressure is applied by hand to the punch, the internal springs absorb the compressive force, until it reaches a ‘tipping point’. The stored energy is then released, forcing the tip of the punch into the surface of the metal. This leaves an indentation in the surface.

|

|

|

|

|