| |

| CLICK HERE FOR INDEX PAGE |

| |

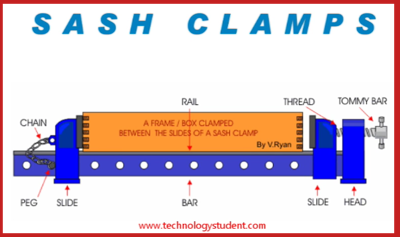

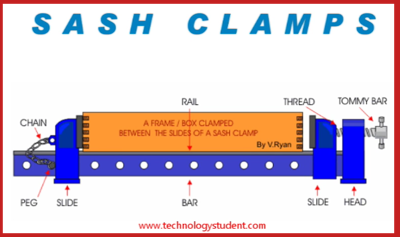

| SASH CLAMPS |

| V. Ryan © 2004 - 2023 |

| |

| VIDEO - USE OF SASH CLAMPS |

|

| |

| Sash clamps are used to clamp work together when it

is glued. They vary in size and are normally used in pairs. The lengths

are normally from 460mm to 1370mm. The bar is made from cold drawn mild

steel and the head and slides made from malleable iron. |

| |

|

| |

| SIMPLIFIED IMAGE |

| |

|

| |

|

|

| |

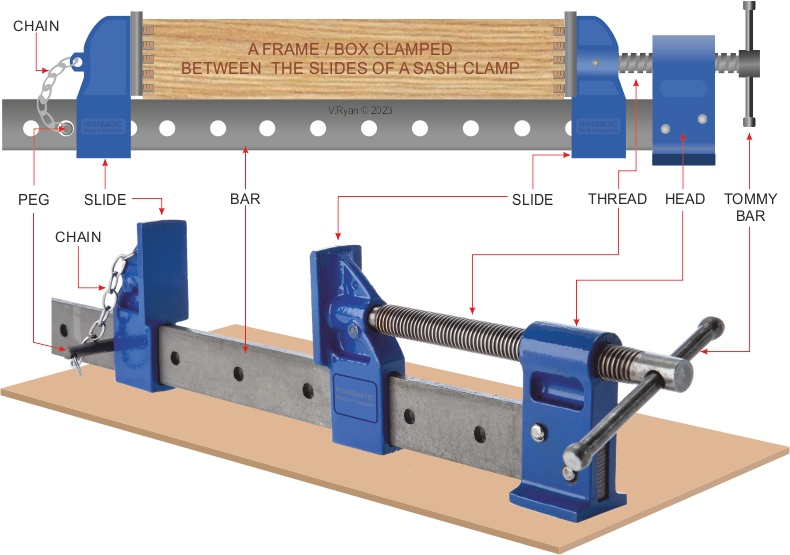

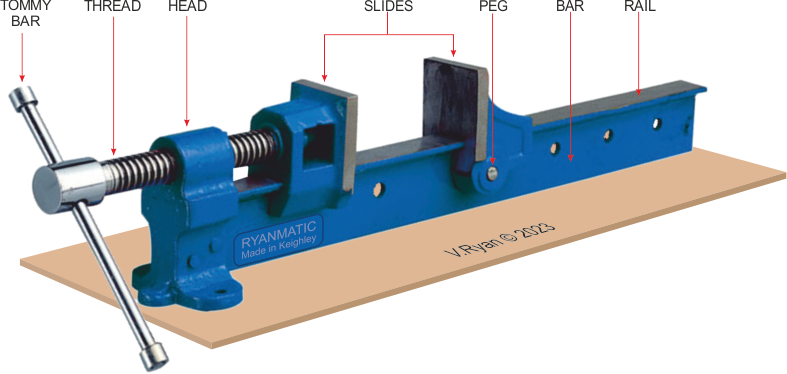

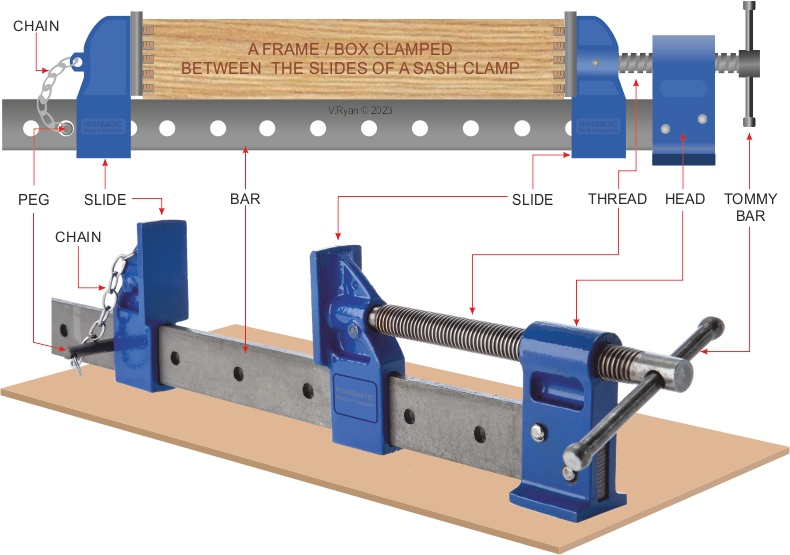

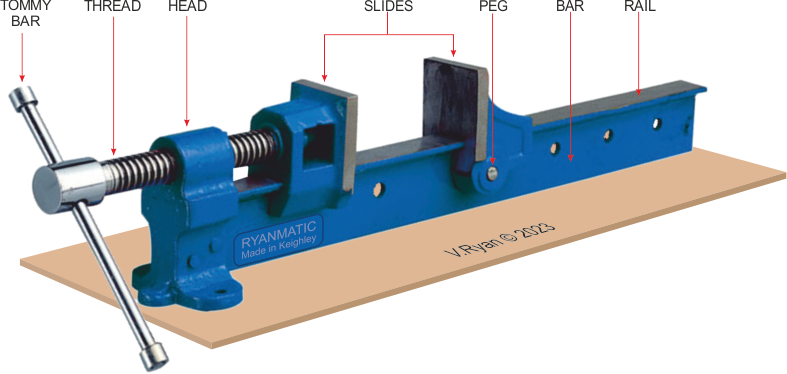

| THE SASH CLAMP (with RAIL) |

| Some sash clamps have a rail, which help control the movement of the 'slide' |

| |

|

| |

| When in use, the sash clamp is placed below the work

to be glued / assembled. The slides are arranged on either side and

scrap wood is placed between each face and the work. This protects the

work when the thread is tightened. The tommy bar is used to tighten the

thread and pressure is increased slowly. |

| |

|

| |

| After clamping a frame, the 'squareness' of the frame

should be tested and adjustments made to the position of the clamps if

necessary. The internal angles of the corners should be 90 degrees. The

90 degree angle is checked with a try square or a rule. A long ruler is

used to check large frames and a try square is used on smaller ones.

When using a ruler the diagonal distances are measured. If both

measurements are the same, the angles at each corner are correct. If the

two measurements differ, the clamps need adjusting until the

measurements are the same. |

| |

|

A RULER BEING USED TO

CHECK

FOR 90 DEGREE ANGLES |

| |

|

|

| |

| A try square is pushed into the each corner of a

smaller frame / box, to check that the 90 degrees internal angle is

correct. |

| |

|

| |

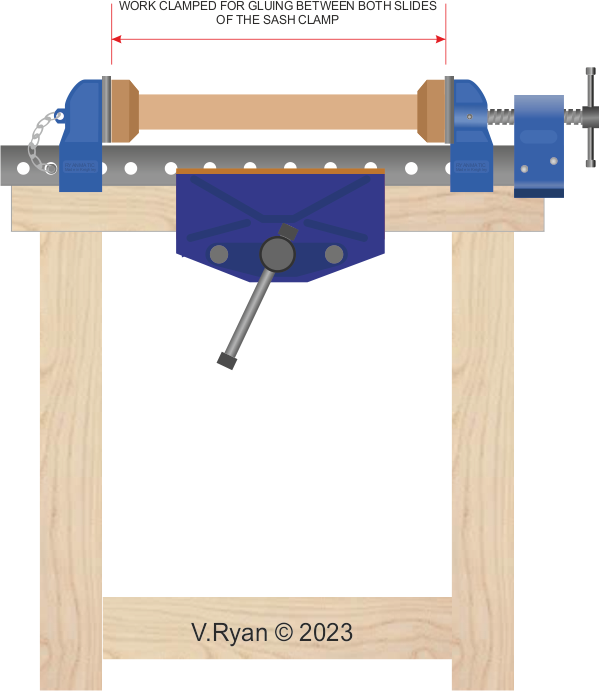

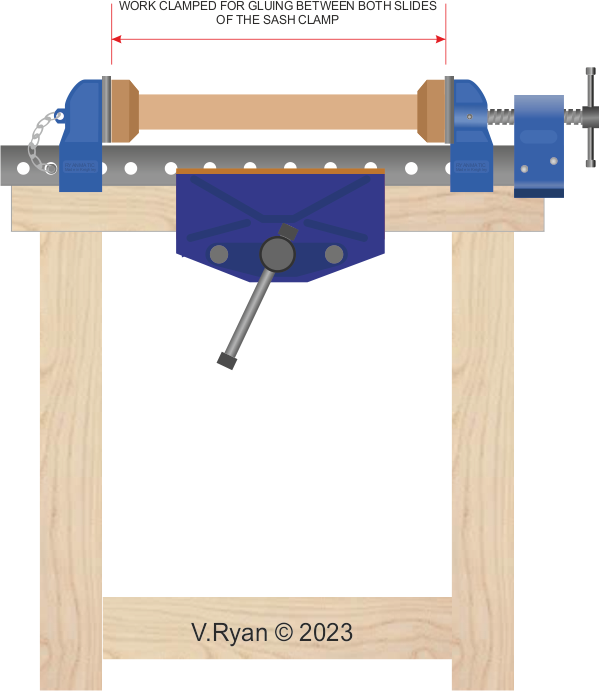

| TIP: Sometimes setting up the sash clamp in a vice as shown below, leaves both hands free to loosen the sash clamp and secure the work between the two slides. |

| |

|

| |

| |

QUESTIONS:

1. Draw a typical sash clamp and

label the important parts.

2. Using diagrams and notes, explain

how a pair of sash clamps are used to ‘clamp together’ a frame / box.

3. Describe how the internal angles

of a frame are checked, after sash clamps have been tightened in

position.

4. What could happen if the internal

angles are not checked and the frame is glued together? |

| |

|

|

| |

| CLICK HERE FOR QUESTIONS/WORKSHEET |

| |

| CLICK HERE FOR EQUIPMENT AND

PROCESSES INDEX PAGE |

| |

| |