|

VACUUM FORMING V. Ryan © 2001-2022 |

|

|

|

|

|

|

|

| Vacuum Forming - Box Learning Exercise (Independent Learning Exercise) | |

|

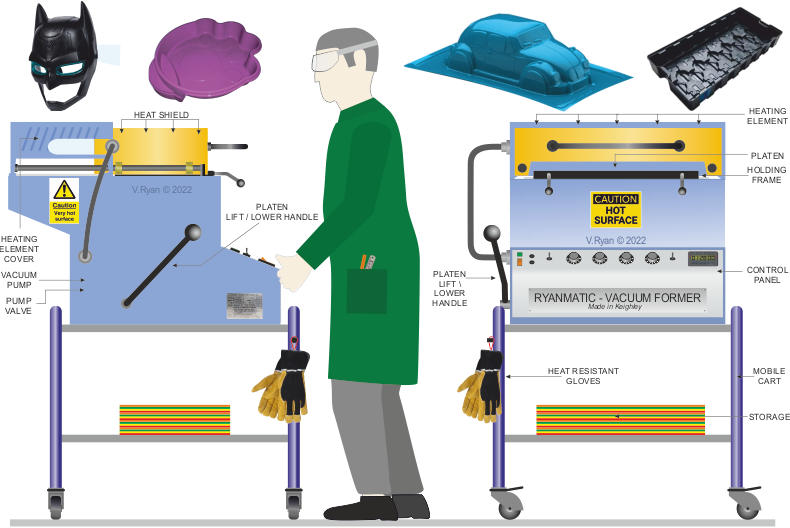

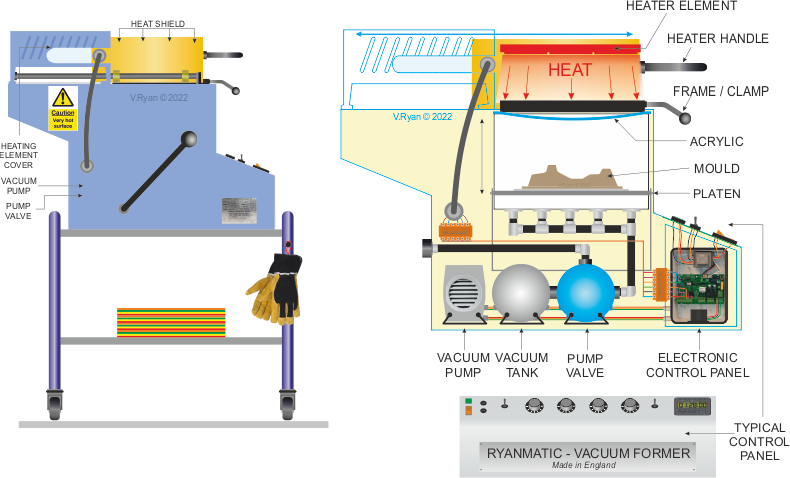

Vacuum forming is a technique that is used to shape a variety of plastics. In school it is used to form/shape thin plastic, usually plastics such as; polythene and perspex. Vacuum forming is used when an unusual shape like a ‘dish’ or a box-like shape is needed. Below you can see the stages involved in vacuum forming. |

|

|

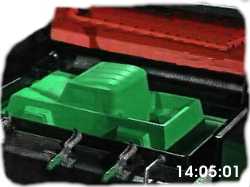

To the right is an example of a vacuum formed toy. The simple 'lorry' mould has been placed in a vacuum former and a compressed polystyrene sheet has been placed above it. The polystyrene has been heated and then vacuum formed to the shape of the mould. |

|

|

Many everyday items have been vacuum formed in this way. Look around your home - list some examples. as a guide - some food products are packaged in vacuum formed materials. |

|

|

IMPORTANT - CLICK HERE FOR AN EXAMPLE OF VACUUM FORMING (ANIMATION) |

|

|

THE STAGES INVOLVED IN VACUUM FORMING |

|

|

|

|

|

Below are the stages involved in the vacuum forming of a small 'plastic' dish or bowl |

|