| CLICK HERE FOR INDEX PAGE | |

| GAS WELDING - OXYACETYLENE | |

| V. Ryan © 2016 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| VIDEO - AN INTRODUCTION TO GAS WELDING - OXYACETYLENE | |

|

|

|

Oxyacetylene gas welding is commonly used to

permanently join mild steel. A mixture of oxygen and acetylene, burns as

an intense / focussed flame, at approximately 3,500 degrees centigrade.

When the flame comes in contact with steel, it melts the surface forming a

molten pool, allowing welding to take place. Oxyacetylene can also be used

for brazing, bronze welding, forging / shaping metal and cutting. |

|

|

|

| PREPARING THE CYLINDERS FOR WELDING | |

| Slowly open the main valve of the acetylene

tank and adjust the acetylene pressure regulator to 5PSI (pounds to square

inch). Open the needle valve on the torch and adjust the pressure on the acetylene regulators to show 5PSI. Close the needle valve. Go through the same procedure for the oxygen cylinder. |

|

| IGNITING THE ACETYLENE / OXYGEN MIXTURE | |

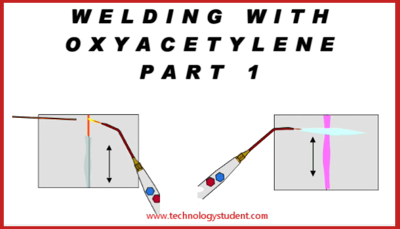

| TURNING ON: Acetylene slowly turned on (quarter/half turn of the needle valve) and ignited, producing a small flame. At this stage, a small amount of soot/smoke is given off the end of the flame. |

|

| Acetylene increased and oxygen turned on slowly. |  |

| Acetylene increased slowly and oxygen more rapidly, to produce an intense, localised flame, capable of precise welding. |  |

| TURNING OFF: Turn off the oxygen first, followed by the acetylene |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | |