| |

| CLICK HERE FOR INDEX PAGE |

| |

SMALL SCALE ALUMINIUM CASTING

PREPARING THE COPE (TOP BOX) |

| V. Ryan © 2008 - 2009 |

| |

| |

| Aluminium can be used as a material for small

scale casting. Aluminium looks similar to pewter but has a much higher

melting point (650 - 700 degrees centigrade). It also is stronger and more

resistant to ‘knocks’ and scratches. It is much cheaper than pewter but

must be heated for quite a long time on the brazing hearth before it

becomes molten. |

| |

|

|

A base is prepared. This has two holes that will hold

the sprues in place whilst the casting sand is used to fill the box. The

sprues will eventually form the holes down which the molten aluminium will

be poured and rise during the casting operation.

Small casting boxes are used if small casts are to be manufactured. The

top casting box is called the ‘cope’ and the lower box is the ‘drag’. |

| |

|

|

| |

When the sprues, base and sides are in position,

casting sand (normally petrabond) is built up in the casting box (the

cope).

A small fine sieve is used to ensure lumps’ of petrabond are broken down

and that only fine sand is allowed to build up around the sprues. Hands

and fingers can be used to compress the sand. |

| |

|

|

|

| |

| Sand is then built up around the sprues, above the

level of the box. This sand will eventually prevent excess molten

aluminium from spilling over the side of the casting box (the cope). |

|

|

| |

|

|

| |

| A small trowel or even a spoon is used to ‘dig’ gates

around each sprue. The aluminium will be poured into the gate of one of

the holes made by the sprues, flowing down into the cavity and rising up

the other hole. |

| |

|

| |

|

|

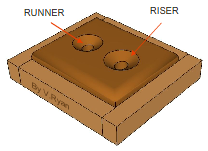

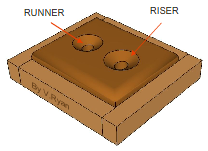

The sprues are carefully removed leaving the holes that

are now known as the ‘runner’ and ‘riser’.

The molten aluminium will be poured into the ‘runner’ and rise up the

‘riser’.

The COPE - the top casting box is complete. |

| |

|

|

| |

| CLICK HERE FOR NEXT ALUMINIUM

SMALL SCALE CASTING PAGE |

| |

| CLICK HERE FOR

EQUIPMENT AND PROCESSES INDEX PAGE |

| |

| |