| CLICK HERE FOR INDEX PAGE | |

| WHAT IS A PRODUCTION LINE? | |

| V. Ryan © 2009-2023 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET | |

|

Many products are

manufactured and assembled on a production line. Before the introduction

of computer control and robots production lines were operated by people.

Each person would carry out a limited number of tasks or even just one

task and the product would then be passed down the production line to the

next person. This would continue until the product was completely

assembled. Some modern production lines still operate in the same way whilst others rely on robots and computer control or a combination of people and machines. |

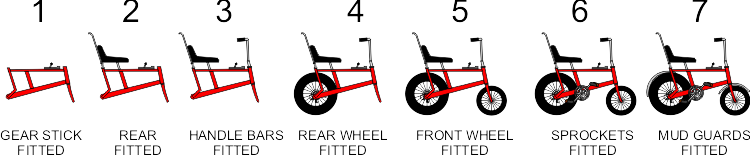

| The example production line seen below has been simplified. This production line is for the assembly of a bicycle (seen above). As the bicycle frame travels down the production line each person at a workstation workstation has a specific task to carry out ( see below). | |

|

|

|

|

|

|

| ADVANTAGES: A production line

is a very efficient way of manufacturing and assembling a product. A car

is composed of thousands of components and yet hundreds of cars roll of

the production line of a typical car plant every day. If each car was to

be assembled by a group of individuals in a garage rather than on a

production line it could take months to produce just one. DISADVANTAGES: However, the workers on production lines often complain that little skill or training is required to complete their individual tasks and that working on a production line is extremely boring and unfulfilling. Workers often see their task as not being very important as they are just producing one small part of a larger product made up of thousands of components. |

|

The link below, takes you to a five-minute video showing how the Tesla Model S is manufactured. |

|

| CLICK HERE FOR NEXT PRODUTION LINE PAGE | |

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |