| CLICK HERE FOR INDEX PAGE |

| |

| ROBIN DAY POLYPROP CHAIR - MANUFACTURING THE FRAME |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

|

| |

|

|

| |

|

The steel tube is cut to size using a guillotine. |

| |

|

|

The burr is removed by hand using a hand file. |

| |

|

|

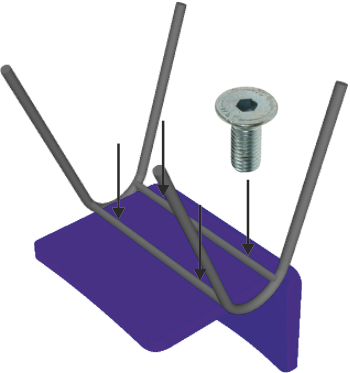

A jig is used to form the tube / legs to the correct curve and angles, after heating to ‘red heat’. |

| |

|

|

| |

|

The supporting rails for the underneath of the chair, are manufactured. The ends of the tube are ‘pinched’ so that welding is easier. |

| |

|

|

The supporting rails are drilled and ‘de-burred’ to remove sharp edges. |

| |

|

|

The joints are gas welded. These provide a permanent and strong joint, that allows a little flexibility in the frame. This absorbs sudden shocks, such as people sitting heavily on to the seat. |

| |

|

|

| |

|

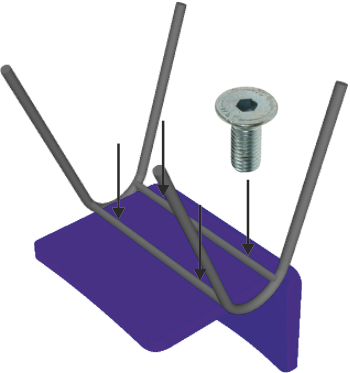

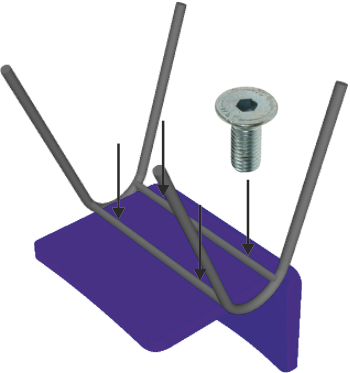

Metric screws are used to fix the seat in position. This means that the chair can be dismantled and repaired or recycled. |

| |

|

|

A final quality control test is carried out, checking for any faults. |

| |

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE |

| |

|

| |

|