| CLICK HERE FOR INDEX PAGE | |

| TABLE - CIRCULAR SAWS | |

| V. Ryan © 2006-2023 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET | |

|

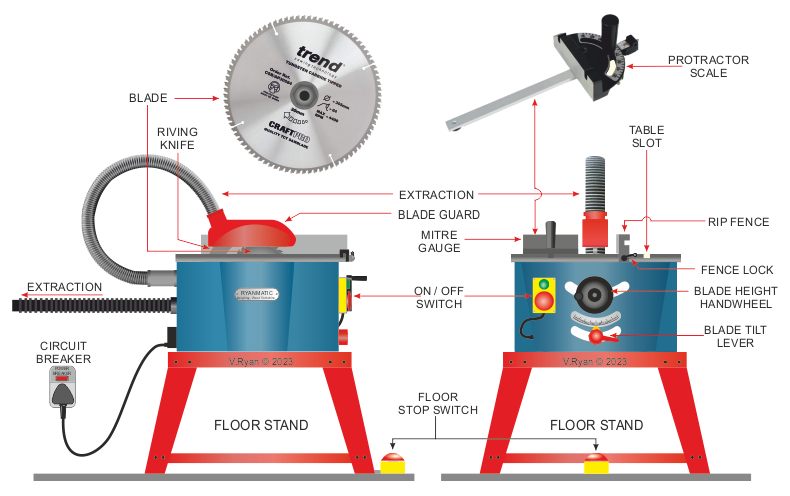

Table circular saws are used for cutting woods to

size . They are extremely powerful and dangerous if used incorrectly.

DIY table circular saws are ideal for cutting manmade boards such as

plywood and MDF and natural woods up to a size of approximately 50mm

thickness. They can be used to cut materials for joinery, furniture and

windows. A table circular saw is normally supplied with a floor stand

and this lifts the saw up to a safe working height. Saws of this type

are a necessary piece of equipment for heavy joinery work. |

|

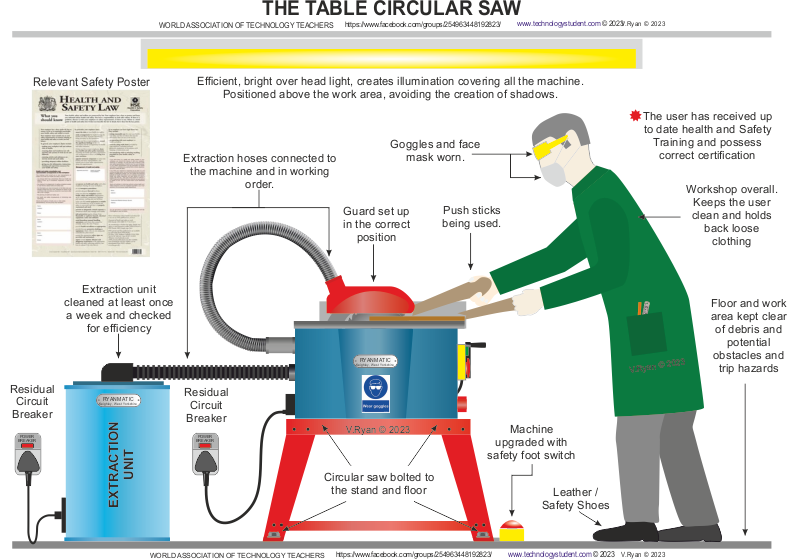

| Push sticks allow the machine operator to keep his / her hands away from the saw blade. Push sticks are usually made from wood and they are used to push material through the cutting area of the machine. The example below, shows wood being pushed along the rip fence, by two push sticks. The main advantage of this technique, is that the operators fingers are well away from the moving blade. Also, the push stick can be positioned close to the blade, helping to maintain control of the material. | |

|

|

|

1. Always plug

power tools into a RCB (circuit breaker) as a safety measure against

electrical faults. |

|

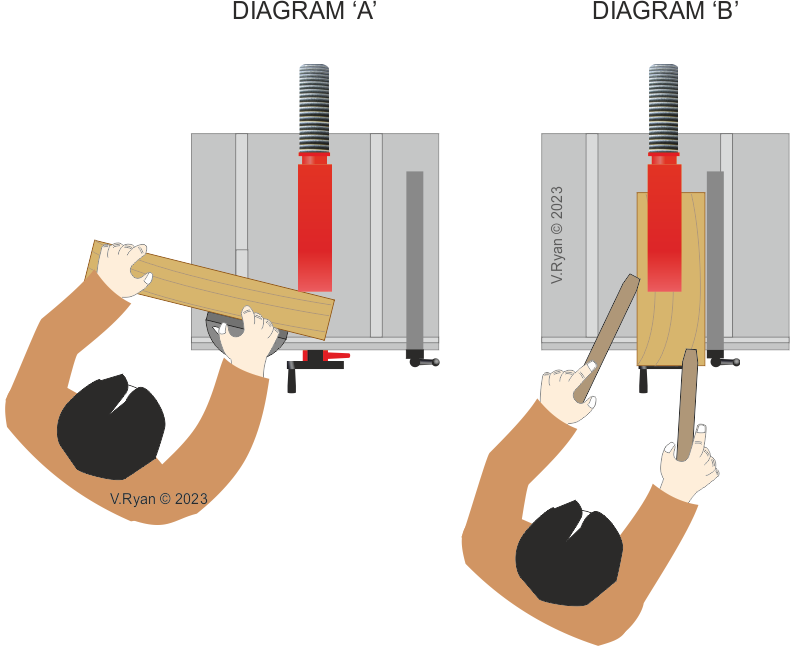

| Diagram ‘A’ shows the

mitre guide being used. This allows the wood being machined to be cut

accurately at a set angle. The mitre guide can be set to a range of

angles. This is a useful, simple accessory. Diagram ‘B’ shows push sticks being used. They are used to push / guide the wood along the fence and towards the rotating blade. Push sticks must always be used if the operators hands move too close to the circular saw. The distance between the fence and blade can be set to different distances allowing for a range of widths of material to be cut. |

|

|

|

| LABELLED DIAGRAM - TABLE CIRCULAR | |

|

|

| SAFETY AND THE CIRCULAR SAW | |

|

|

| CLICK HERE FOR NEXT TABLE CIRCULAR SAW PAGE | |

| CLICK HERE FOR POWER TOOL INDEX PAGE | |