| |

| CLICK HERE FOR INDEX PAGE |

| |

| POWER SCREWDRIVERS |

| V. Ryan © 2006 - 2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

Everyone has used a manual screw driver to turn a

screw that refuses to move or one that is very difficult to turn. The

result is a sore or blistered hand. Power screwdrivers are the answer

especially if a large number of screws need to be fixed in position.

A large range of power screwdrivers exist and even the cheapest types

are often very powerful and most are supplied with a range of

attachments. As a minimum a battery charger and a number of screwdriver

blades will be part of the overall kit. |

| |

|

| |

|

|

| |

|

| |

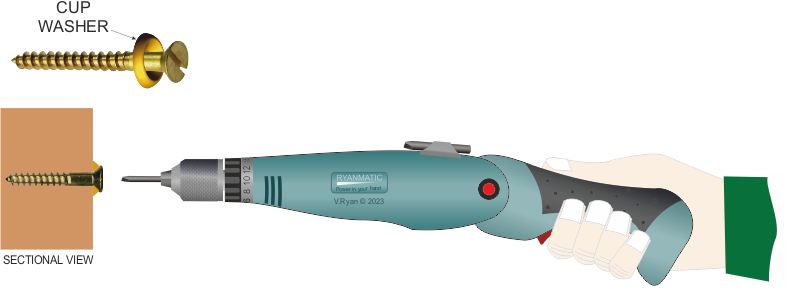

1. The

screwdriver blade is dangerous. Both hands should be behind the blade

whilst it is turned. Never, place a hand in front or alongside the

blade. If the blade slips it can tear into flesh, producing a nasty

injury.

2. Always wear safety goggles to

protect the eyes. Never operate equipment like this without eye

protection.

3. Select a power screwdriver with a

comfortable handle. A poorly designed handle will cause blisters.

4. Use the correct screwdriver

blade. Eg. a 'Crosspoint', Slot head or 'Supadriv' type. An ill fitting

blade will slip as the screw is turned and can cause injury.

5. Always check that electrical

wires or water pipes are not in the area. Forcing a screw into an

electrical wire can be extremely dangerous.

6. Always seek instruction /

training from an appropriately qualified instructor before using any

tools, especially power tools. |

| |

|

|

| |

|

| |

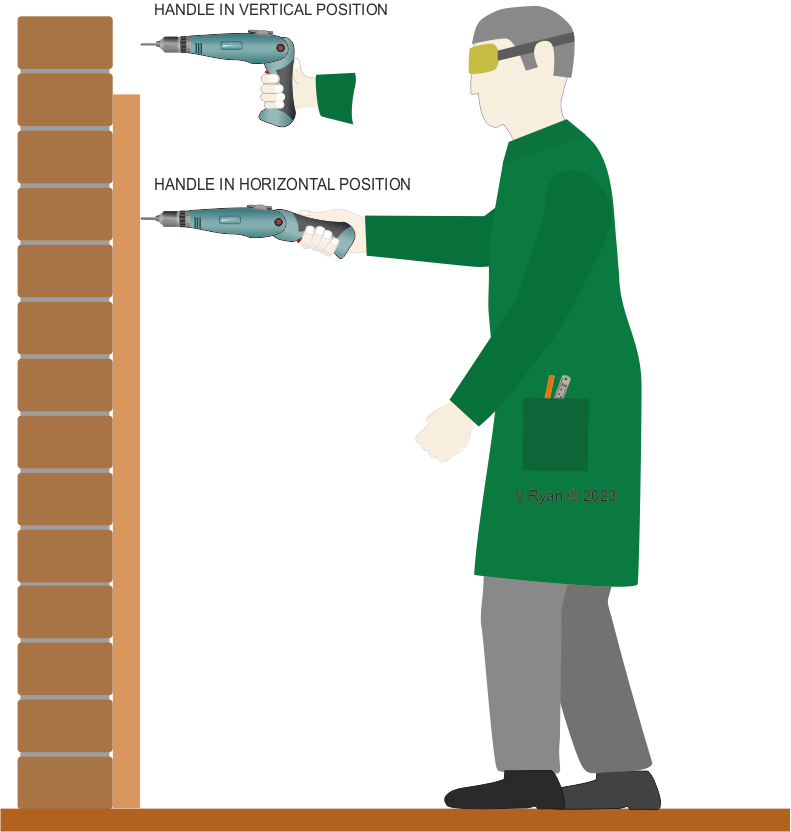

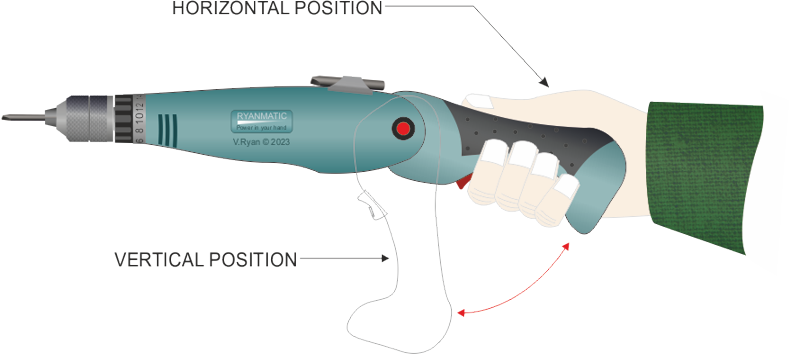

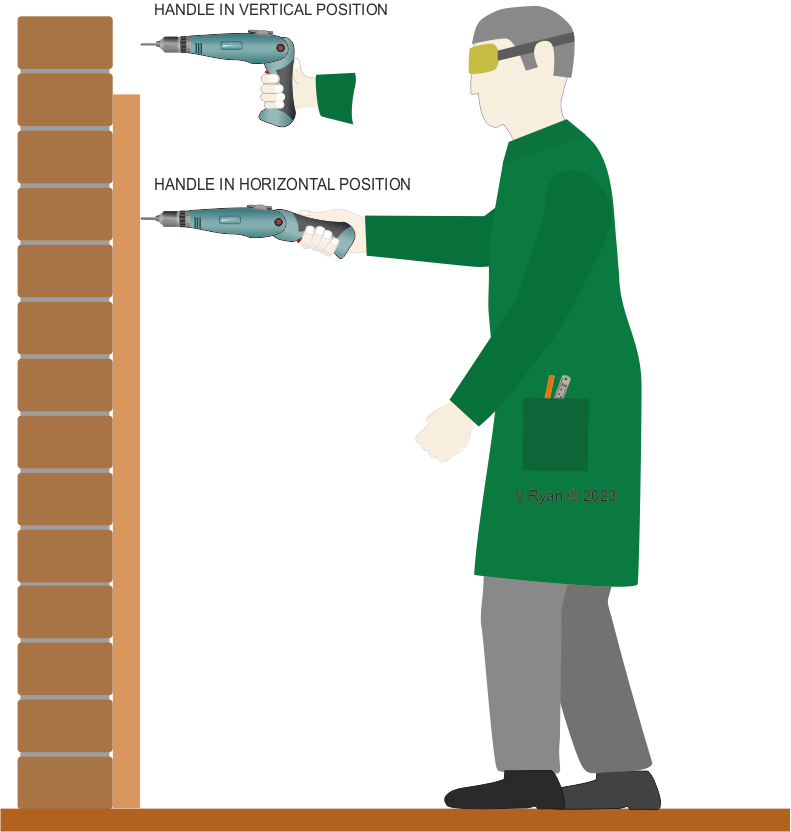

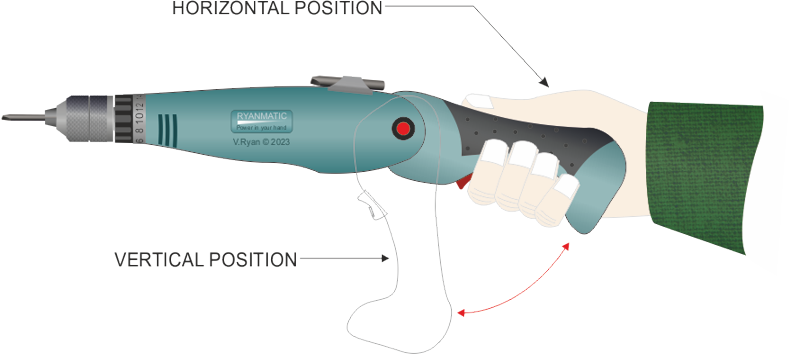

| Depending on the model and make of power screwdriver,

the handle will have two positions. The handle can be locked in a level

position as shown in the diagram above OR it can be locked into a

vertical position. |

| |

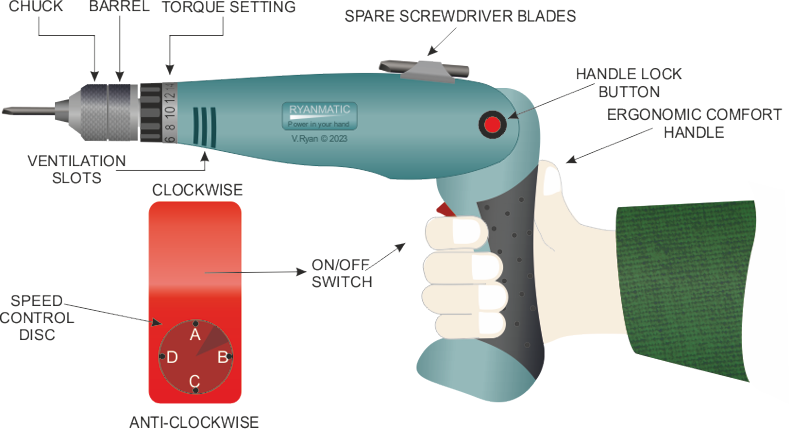

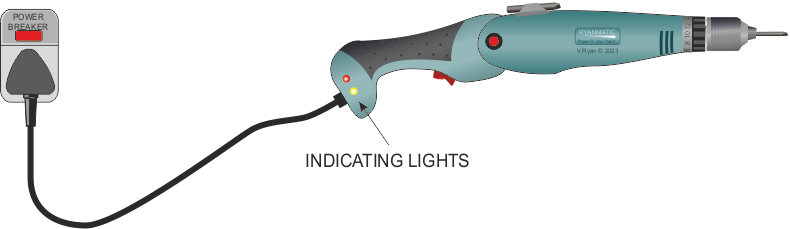

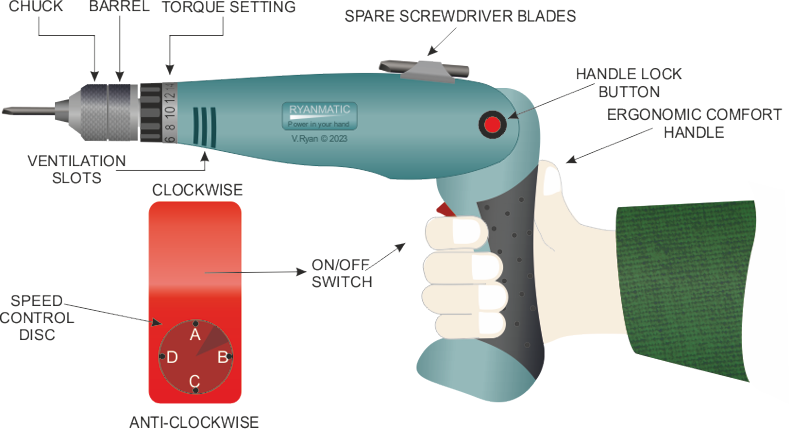

Power Screwdrivers are usually variable speed and

torque. The example below has a speed control disc on the ON/OFF button.

Pressing the top of the ON/OFF button turns the chuck and screwdriver

blade in a clockwise direction. Alternatively, pressing the bottom of

the ON/OFF button turns the chuck in an anti-clockwise direction.

Torque is often misunderstood. Torque is the amount of power supplied to

the chuck. For example. The speed (RPM) may be quite low and the chuck

turns slowly - However - the torque may be high and the chuck turns

powerfully and powers screws into the most resistant of materials. The

torque setting can be adjusted by turning a dial (shown on the diagram

below). Sometimes the setting will be set quite low. This helps prevent

over tightening of a screw. |

| |

|

| |

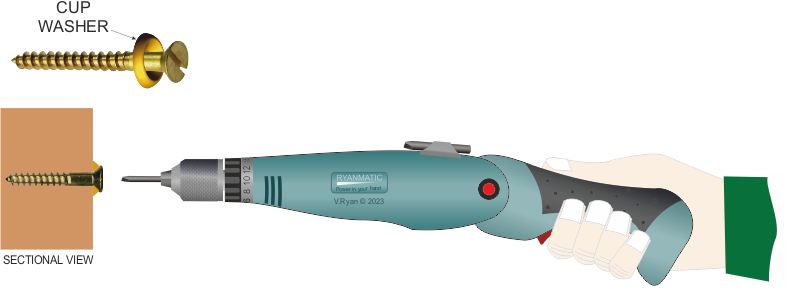

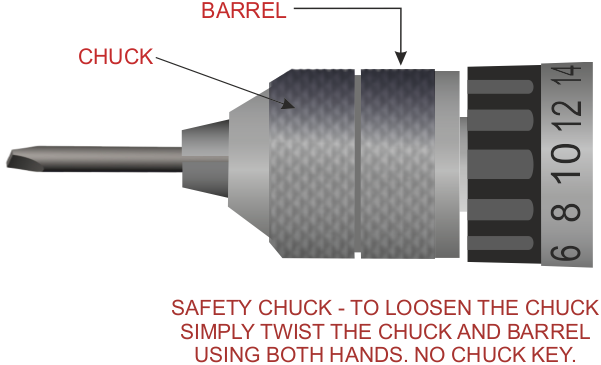

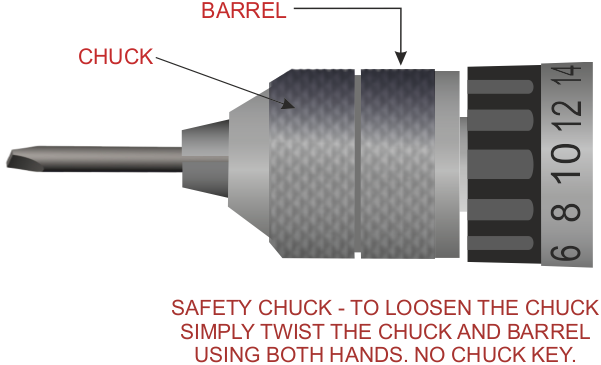

| Safety / self-locking chucks are very common. These

to not need a chuck key and are used by simply turning the chuck and the

barrel by hand, in opposite directions. The screwdriver bit locks in

position. |

| |

|

| |

|

|

| |

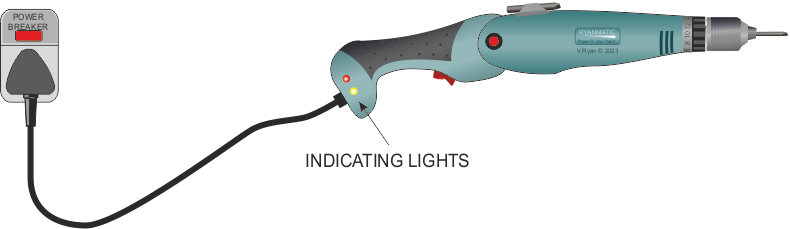

| To charge most power screwdrivers, simply plug them

into the mains. On some models a red indicator light will show when the

internal battery is charging. When charging is complete (1 to 3 hours)

the green indicator light will show. Then the screwdriver can be

disconnected from the mains and used. |

| |

|

| |

| TYPICAL SCREWDRIVER BIT SET |

| |

|

| |

| CLICK HERE FOR POWER TOOLS INDEX PAGE |

| |