| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| INJECTION

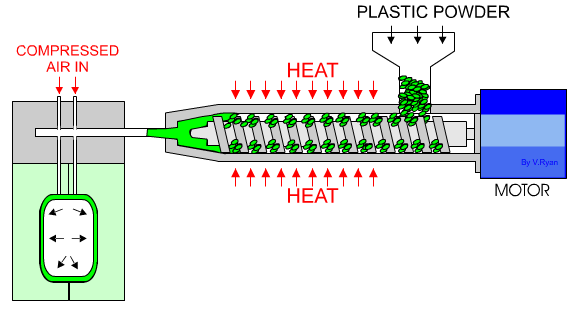

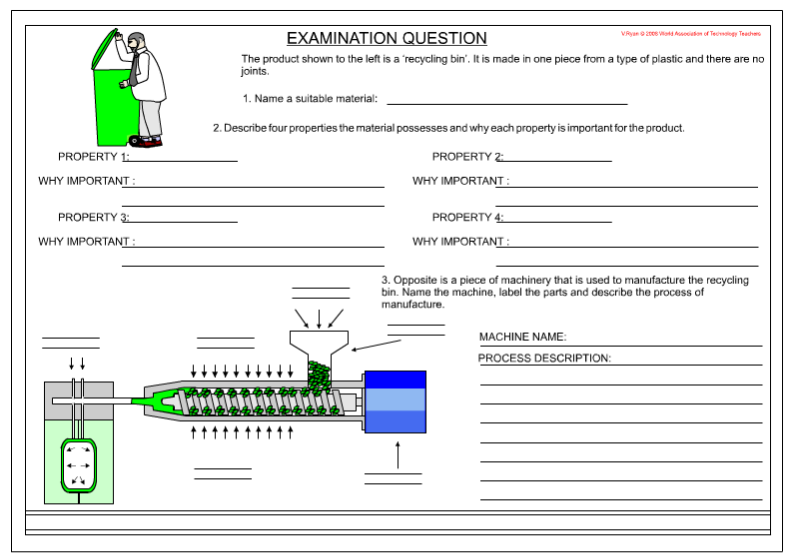

MOULDING: The diagram below shows one method of manufacturing the recycling bin. HDPE (high density polyethylene) is ideal for this type of manufacturing technology (see diagram below). The HDPE granules / powder is placed into the hopper. It drops down on to a rotating thread and travels along its distance. During this process the granules / powder is heated and becomes fluid. It is then injected into a mould of the bin. Once cool it can be taken out and excess HDPE is trimmed away and recycled. |

|

|

|

| BLOW MOULDING: | |

| Blow

moulding follows the same stages of manufacture as injection moulding.

HDPE (high density polyethylene) is ideal for this type of manufacturing

technology (see diagram below). The HDPE granules / powder is placed into

the hopper. It drops down on to a rotating thread and travels along its

distance. During this process the granules / powder is heated and becomes

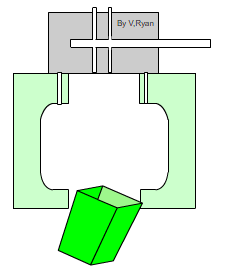

fluid. However, when it reaches the mould compressed air is also blown into the mould. This pushes the HDPE around the edges of the mould, forming a hollow shape, in this case the recycling bin. |

|

|

|

|

|

|

When the HDPE is cool it is removed from the mould and excess HDPE is trimmed away - leaving the bin. |

| EXAMINATION QUESTION | |

|

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |