| CLICK HERE FOR INDEX PAGE |

| |

| COMMERCIAL EMBOSSING |

V.Ryan © 2020 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| Commercial embossing is usually, a batch or continuous production process. A simplified diagram of typical embossing machinery is shown below. When embossing is applied by hand, a stamp is used to press the pattern into the card. However, this commercial machinery employs two roller cylinders. The top roller has the pattern, which will be pressed into the card. The bottom roller has a rubberised surface and supports the card, as it travels through the machinery. |

| |

|

| |

|

|

| |

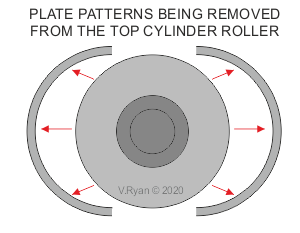

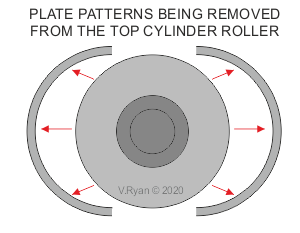

The patterned embossing plates, surrounding the top roller, can be removed and replaced with a different one. The patterns are normally in two halves and they are bolted on to the cylinder roller.

This means that a range of embossing patterns, can manufactured and stored for future use. The manufacture of the patterns is an expensive process. Consequently, this type of embossing process is normally for batch or continuous production. |

|

|

| |

| THE EMBOSSING MACHINE |

| |

|

| |

|

|

| |

| SAMPLES OF EMBOSSED PAPER / CARD |

| |

|

| |

| SAMPLES OF EMBOSSED SHEET METAL |

| |

| This commercial embossing process, can also be applied to when ferrous and non-ferrous sheet metal. The machinery for embossing metal is much more substantial, due to the pressure required when pressing a pattern into a ‘metal’ surface. |

| |

|

| |

| |

| CLICK HERE FOR GRAPHICS INDEX PAGE |

| |

|

| |

|