V.Ryan © 2020

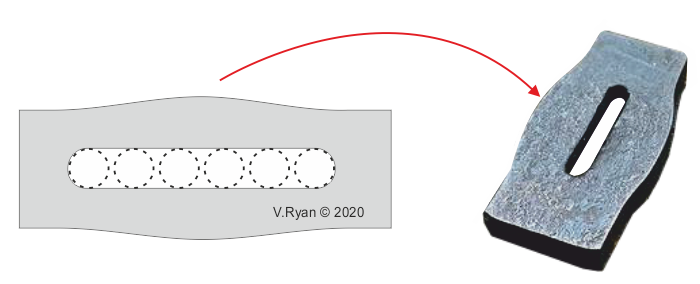

‘Punching’ and ‘drifting’ is a common practice in forgework. Punches are supplied in a range of sections, from round and square to rectangular. Punches are used first to drive a hole through the metal being forged, followed by a drift, which smooths and is used to widen the ‘hole’.

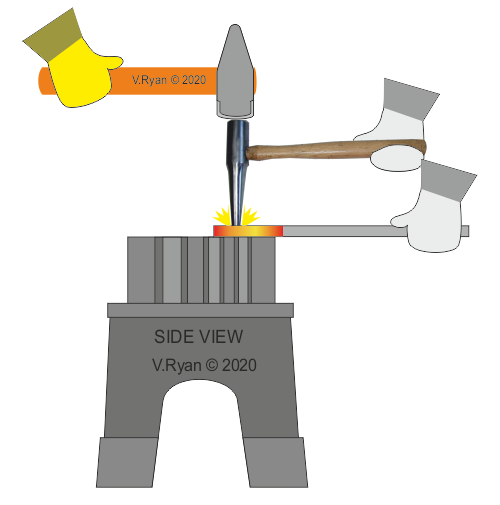

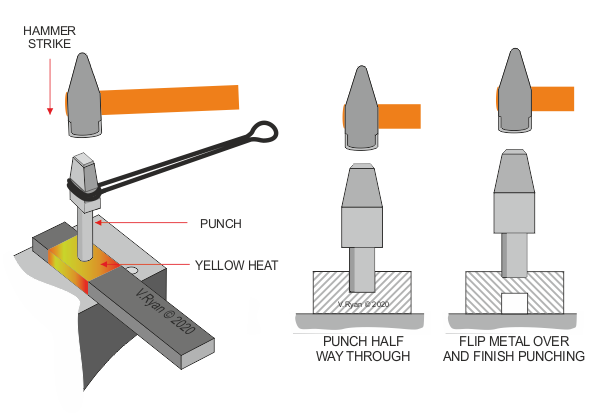

This process starts with the metal being heated to yellow heat, in the forge. It is then placed on the face of the anvil, and a punch is used to drive a hole, approximately half way through. The metal is flipped over and the metal is punched from the opposite side. This means that punching does not go through to the surface of the anvil, which could damage it. ‘Punching’ must be completed quickly, so that the temperature of the metal is maintained. The punch will need cooling through quenching, during the process. The side of the metal in contact with the anvil, will eventually cool below yellow heat, preventing further punching.

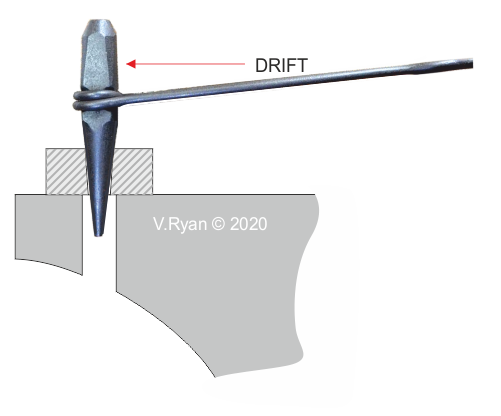

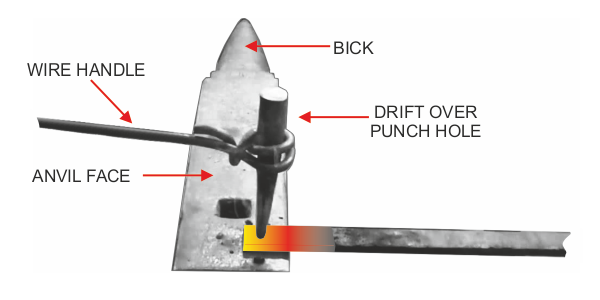

The metal will need reheating, so that a drift can be used to widen the hole to the correct size. The drift will also produce a ‘smooth’ finish.

Please note: ‘drifting’ should be attempted over the punch hole of the anvil, or using one of the holes through a swage block.

Drifts are tapered. The one seen opposite, is being used over the anvil’s punch hole.