V.Ryan © 2020

Creating a twist in a length of steel, is a typical forging process, seen in many examples of Blacksmith’s work, such as wrought iron gates and railings.

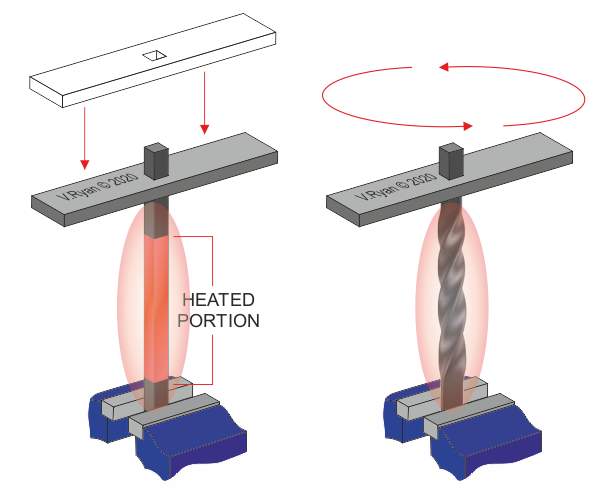

Thin sections can be twisted without the need to heat in a forge. However, larger sections need heating to red heat / yellow heat, and must be a uniform temperature, along the section to be twisted. The forge is the best way of ensuring a uniform temperature.

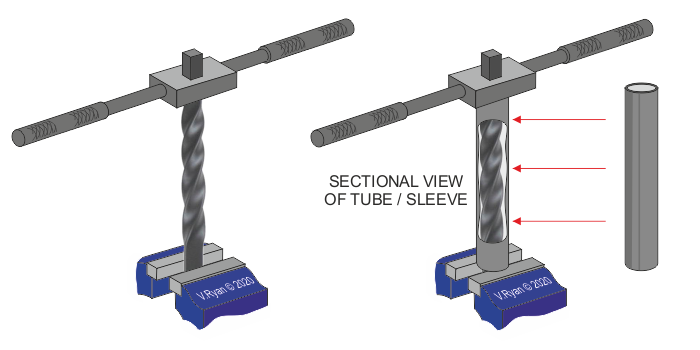

The steel is placed in a vice and a wrench slipped over the top. Homemade wrenches have a square hole, through which the steel fits. The wrench is then turned clockwise (or anticlockwise), usually one or two turns.

The steel twist is then allowed to cool, or quenched in water.