V.Ryan © 2020

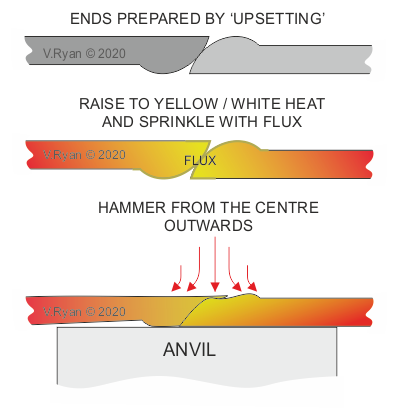

It is important to use flux on the surfaces to be welded together. The flux prevents oxidisation taking place, by providing a protective coating called ‘slag’, with prevents oxygen in the air reaching the metal’s surface. Borax is used as a flux for mild steel and sand for wrought iron.

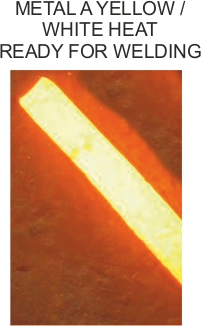

The fire in the Blacksmith’s hearth, must be carefully maintained, in order to achieve the high temperatures required for welding. Also, the heart of the fire must be free of ‘clinker’ (the waste produced by heating coke).

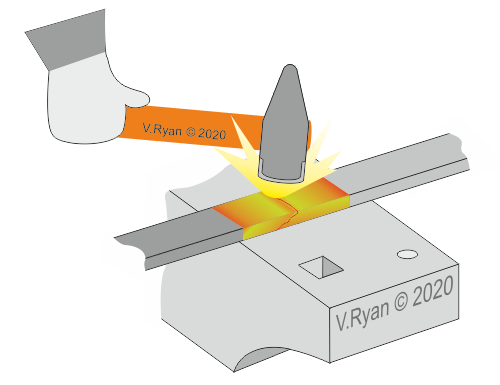

The welding process starts at the centre of the joint, with the Blacksmith working outwards. This displaces any slag / impurities. Working from the outside of the joint inwards, has the potential to lock in any impurities / slag, as hammering progresses. This could lead to poor and weak welded joint.

Hammering starts at the centre of the joint, forcing impurities / slag out of the joint.

Once the joint is made, the Blacksmith concentrates on shaping / forming the joint, so that it is accurate and smooth.