V.Ryan © 2019

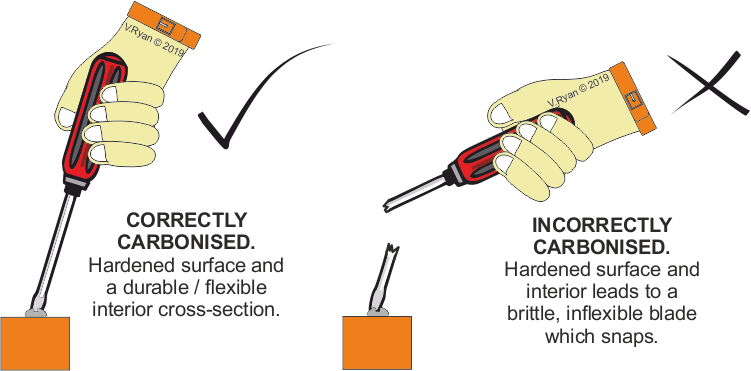

The carbon content of steel, often determines its hardness, ability to resist wear and consequently, its practical application. For instance, a screw driver blade requires a hardwearing surface, to resist wear whilst in use. However, a screwdriver blade that is hardened throughout its cross-section, will be too brittle / inflexible and eventually snap / break. Therefore, retaining a measure of durability / flexibility throughout its cross-section, is a vital characteristic. For this reason, the screwdriver blade has been hardened at its surface (increased carbon content), whilst having a lower carbon content throughout its cross-section.