| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

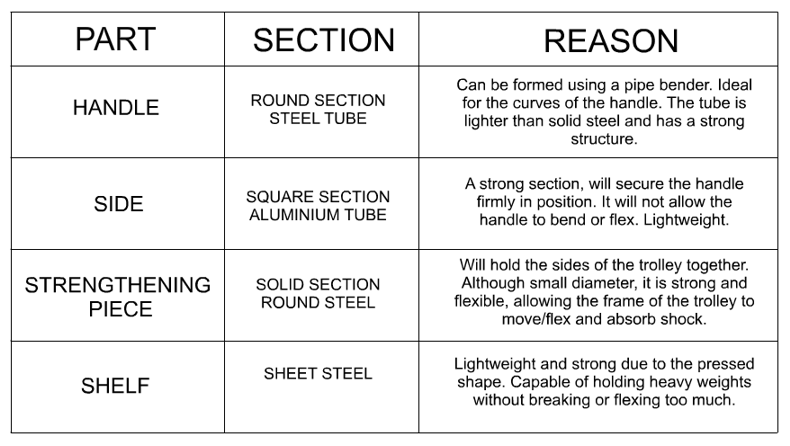

The trolley is manufactured from round section steel tube, solid section

round steel, sheet steel, square section steel tube and square section

aluminium tube. The combination of materials and the use of tube sections, make this trolley lightweight and yet very strong. Using tube saves on weight and increases the overall strength of the trolley’s structure. The aluminium will not rust and the steel parts can be painted, preventing corrosion. The sheet steel shelf has slots cut out of it in order to reduce its weight, without reducing its strength. A pattern has been pressed into the steel as this will increase its overall strength and make the steel sheet more rigid. It also means that the surface of the sheet steel has a grip/tread. This will held hold weights such as heavy boxes, in place when the trolley is moving. |

| MATERIALS - SELECTION AND REASONS | |

|

|

| STEEL AND RUST PREVENTION | |

|

Steel can rust extremely easily and quickly if it is not protected from

the elements, especially water, moisture and humidity. This can be

achieved through the use of paint. Normally a primer paint is applied

first. This helps prevent rust and forms a good surface on which to apply

a second coat of paint. Paints come in a range of colours, making them

idea for a product such as a trolley. Furthermore, paint is relatively

cheap. Alternatively, steel can be galvanised. With this technique a layer of zinc is added to the surface of the steel. The two ways of galvanising steel are, hot dipping and electroplating. |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |