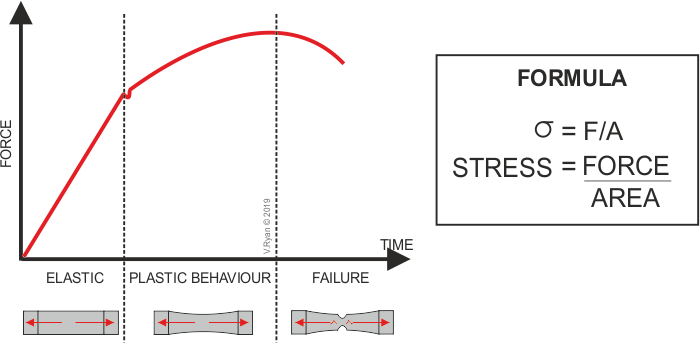

V.Ryan © 2019

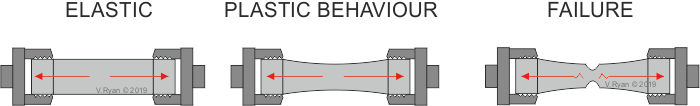

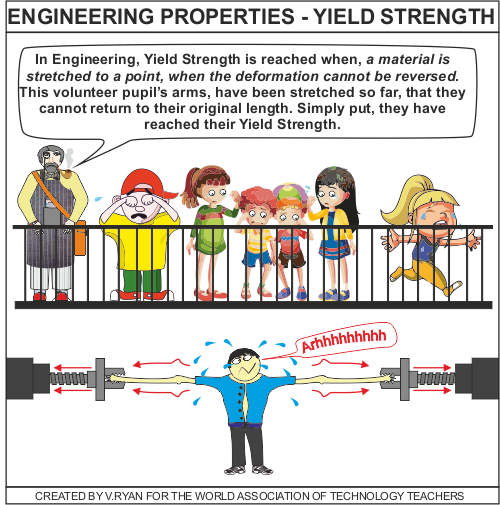

When a material is stretched (put under stress) during a ‘materials test’, it first exhibits ‘elasticity’ (stretches). When experiencing ‘elasticity’, the material is capable of returning to its original shape, if the test is stopped in time and the stress removed. If the test is continued, the material will eventually be unable to return to its original shape, as it will enter the stage called ‘plastic behaviour’. At this point the deformation to the material cannot be reversed, it said to have reached ‘yield strength’ (also called ‘yield stress’). Yield point, is the point at which a material / component fails. Material tests are designed to identify this point, as it is a clear limit, that should not be exceeded.

Stage One - Elastic

Stage Two - Plastic Behaviour

Stage Three - Failure