V.Ryan © 2021

| CLICK HERE FOR INDEX PAGE |

| BUFF STICKS |

V.Ryan © 2021 |

| The finish on a piece of jewellery, contributes significantly to its overall quality. During the making of an item of jewellery and the use of jeweller’s tools, scratches and other minor ‘surface damage’, is likely to occur. It is wise to spend time, removing minor damage such as marks and scratches. This is followed by expert polishing. |

| Cleaning of non-ferrous metal often starts with pickling in an acid solution, followed by the use of files, fine abrasive sheets (emery cloth / wet and dry paper) and even pumice powder. |

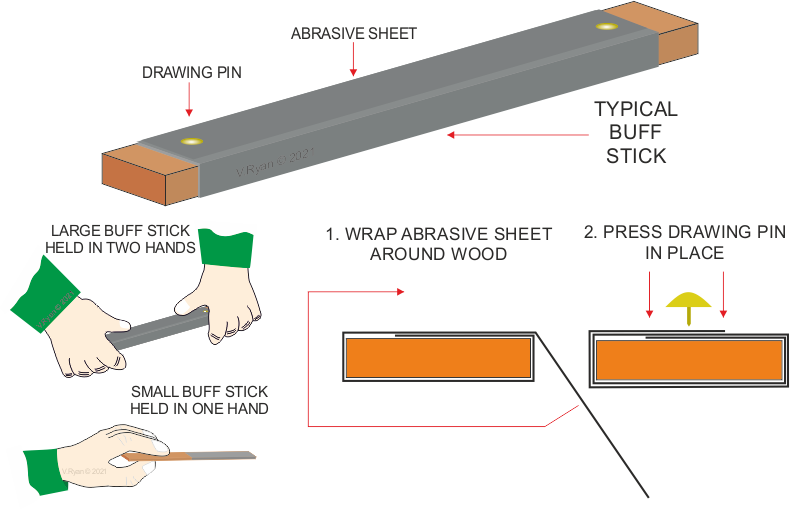

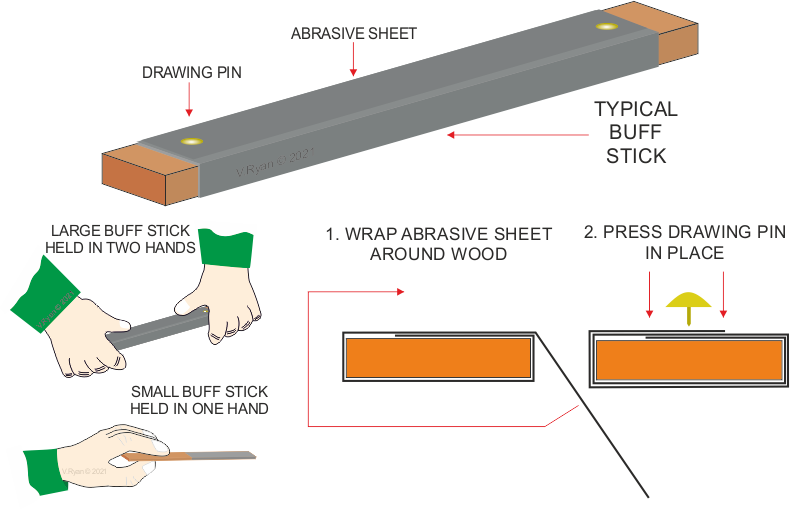

| Buff sticks are very useful abrasive sticks and they are easy to make. They are usually round or square / rectangular in section. Experienced jewellers make a variety of buff sticks, to suit the jewellery they are making. Buff sticks allow a jeweller to work in small corners / areas. |

| The buff stick shown below, has been made by wrapping fine grade abrasive sheet, round a piece of wood, several times. A drawing pin is pushed in each end, holding the abrasive tightly in position. When the abrasive sheet wears out, the pins are removed, the worn part of the abrasive sheet is cut away, revealing fresh abrasive and the drawing pins pushed back in place. |

|

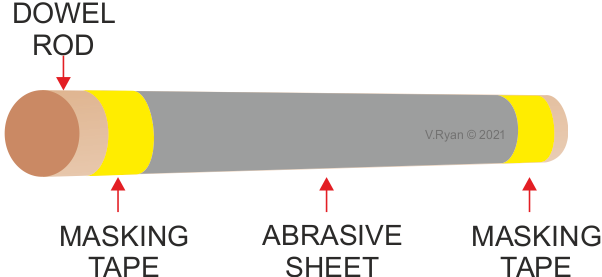

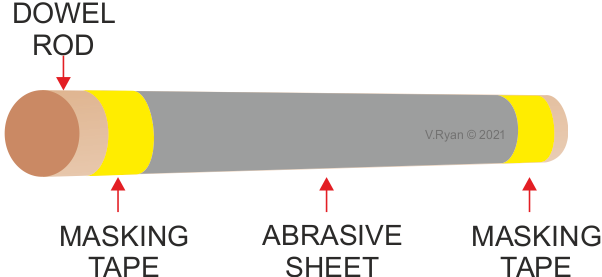

| For a round section buff stick, a piece of dowel rod is suitable. Wrap the abrasive sheet around it. Use masking tape or a drawing pin at either end, to hold the abrasive sheet in position. |

|

| CLICK HERE FOR JEWELLERY INDEX PAGE |

|