V.Ryan © 2021

It is ready for finishing with files, abrasives and polishing.

| CLICK HERE FOR INDEX PAGE | ||

| PREPARING TUFA STONE AND CASTING | ||

V.Ryan © 2021 |

||

| Tufa stone is a soft rock, composed of petrified volcanic ash. It is easy to cut and carve and can be used to form casting moulds. Two pieces of tufa stone, are rubbed together, forming flat surfaces, that fit face to face, without gaps. This is the starting point of the mould. | ||

|

||

| Tufa stone is worked in the same way as a charcoal block, using the same carving tools and equipment. Alternatively, a Pendant Drill or ‘Dremel Multi-Tool’, can be used to carve the shapes. A pouring sprue and air vents are carved into the stone. | ||

|

||

| Below are some of the grinding bits that can be used to carve detailed shapes, forming the mould. | ||

|

||

| The tufa stone surface is ‘carbonised’ with a blow torch. This technique deposits ‘soot’ on the surface, which helps to release the casting, when it has cooled, after pouring. The soot is produced, if a soft gas flame is used, with minimum air / oxygen mix. The flat surface of the second piece of tufa stone, is also carbonised. | ||

|

||

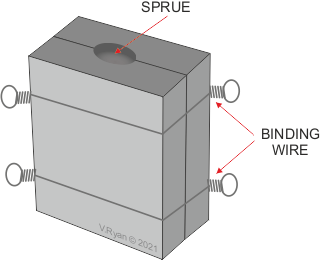

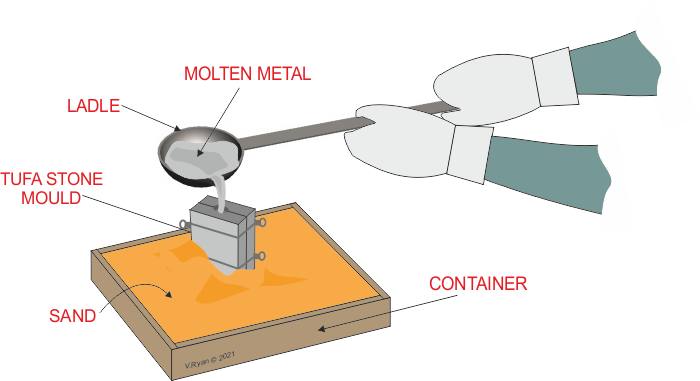

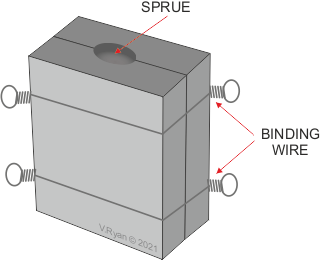

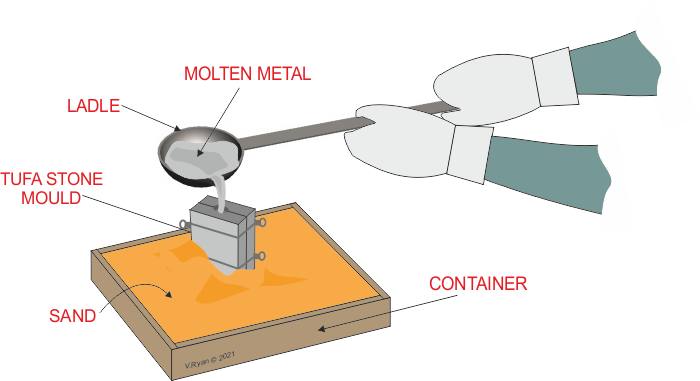

| The tufa stone mould is wired together and placed in a sand box. The sand is ‘piled’ around the mould, holding it in position. The sand will catch any excess molten metal, if it runs down the side of the mould. |  |

|

|

||

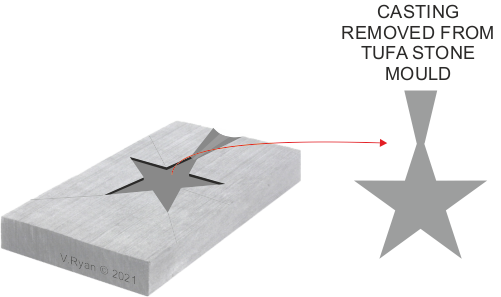

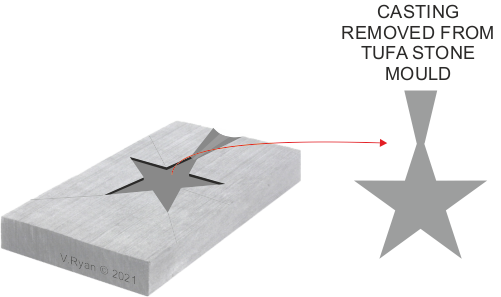

| The casting is allowed to cool and the tufa stone mould is split open. The casting may still be warm, so it should be placed on a steel surface / steel block to finally cool. It is ready for finishing with files, abrasives and polishing. |

||

|

||

| CLICK HERE FOR JEWELLERY INDEX PAGE | ||

|

||