| CLICK HERE FOR INDEX PAGE |

| |

| DELFT CLAY CASTING |

V.Ryan © 2021 |

| |

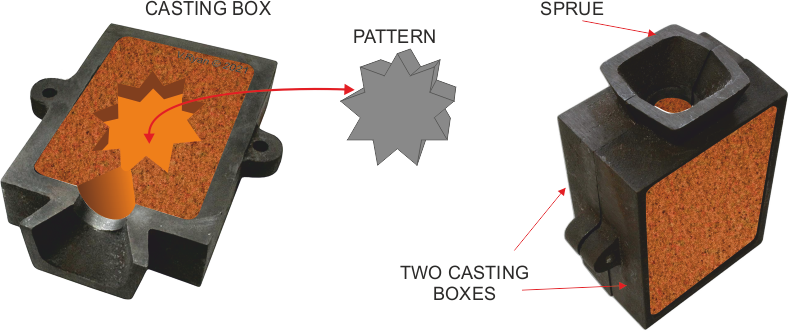

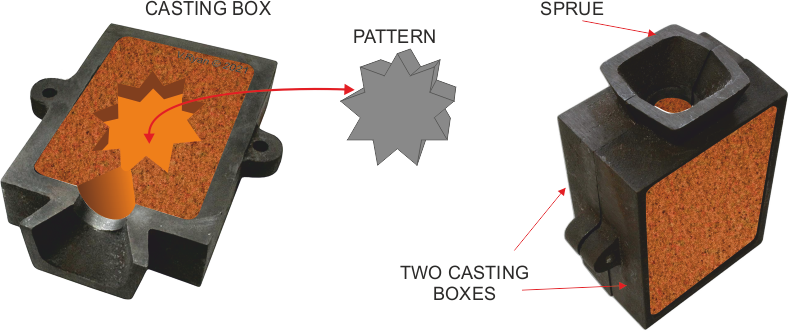

| Delft clay is a very fine sand (mixed with a special oil and clay) and is often used when casting detailed jewellery. It is the type of clay, that will not dry out and can be reused. Ideal for metals such as pewter, silver, gold and brass. Delft clay is often ‘packed’ in casting boxes, such as the ones shown below. The boxes have a built-in sprue, down which the molten metal is poured. |

| |

|

| |

|

|

| |

| The first stage is to break up the delft clay, ensuring that any lumps are broken down. This can be achieved by crushing and manipulating the clay by hand. |

|

|

| |

|

|

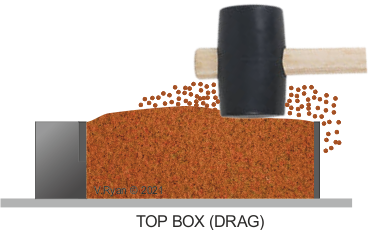

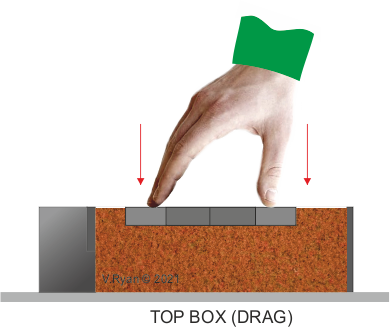

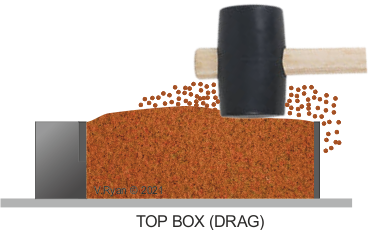

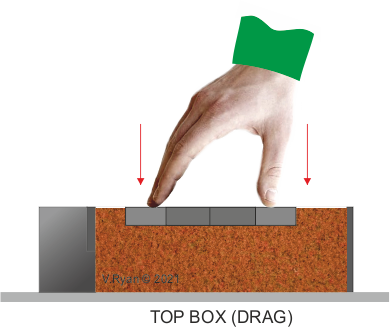

| The first box, called the ‘drag’, is filled with delft clay and compacted using a wooden / rubber mallet. |

|

|

| |

|

|

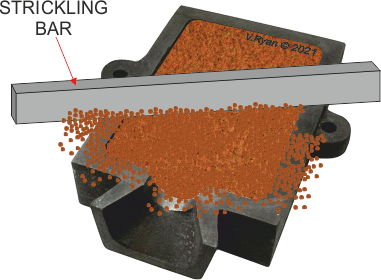

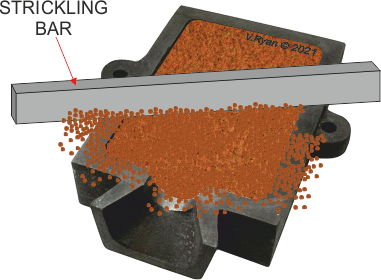

| A straight metal edge, called a ‘strickling bar’, is pushed across the box, levelling the compacted delft clay |

|

|

| |

|

|

| |

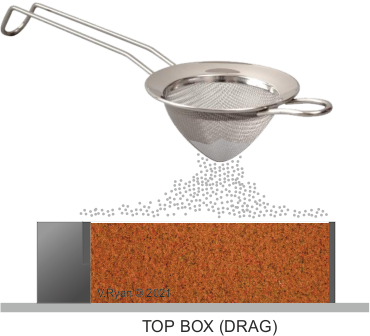

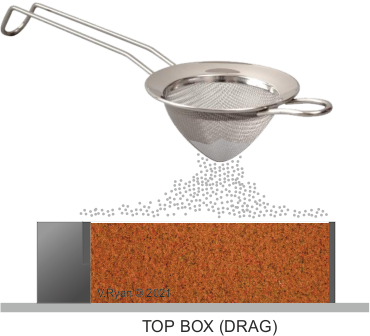

| Parting powder (talcum powder) is sprinkled across the top of the delft clay. This will allow the casting boxes and mould / pattern, to be separated easily later. It prevents them sticking together. |

|

|

| |

|

|

| The mould / pattern is pushed into the delft clay and then carefully removed, leaving an impression of the pattern, called the cavity. |

|

|

| |

|

|

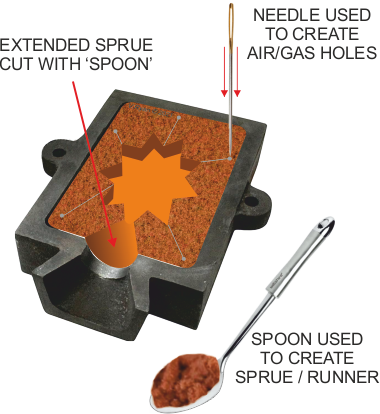

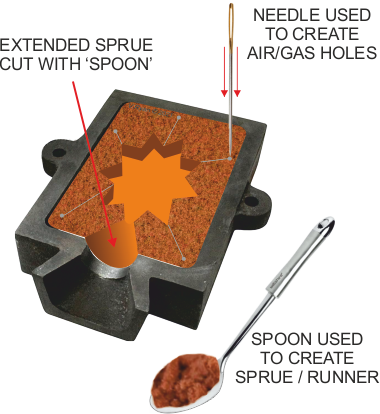

The steel sprue of the casting box, is extended into the sand/clay, carved with a small spoon / knife. This is also called a ‘runner’.

Thin air/gas vents are ‘scratched’ into the surface of the clay and small holes are pushed through the clay, with a thin piece of metal (e.g. a sewing needle). These vents and holes allow gases to escape when the metal is poured.

The second casting box, called the ‘cope’, is prepared in exactly the same way.

|

|

|

| |

|

|

| |

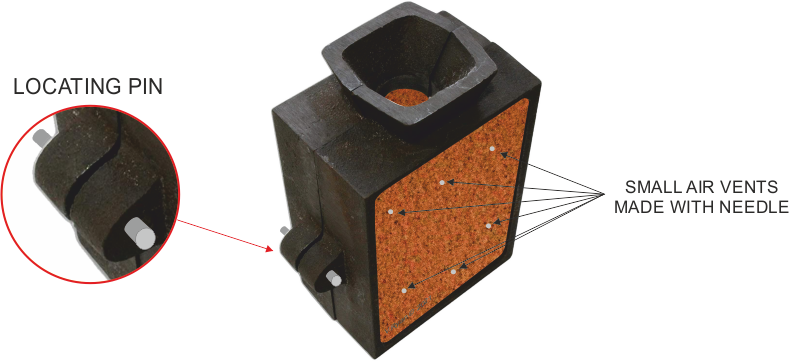

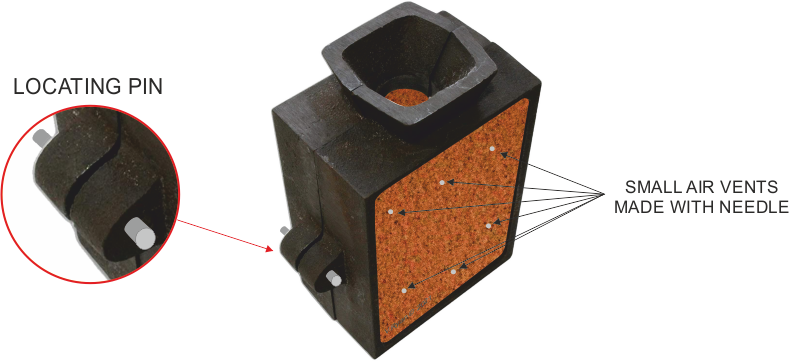

| The two casting boxes (the ‘cope’ and ‘drag’) are put together. Locating pins on either side of the boxes, ensure that they line up with each other. |

| |

|

| |

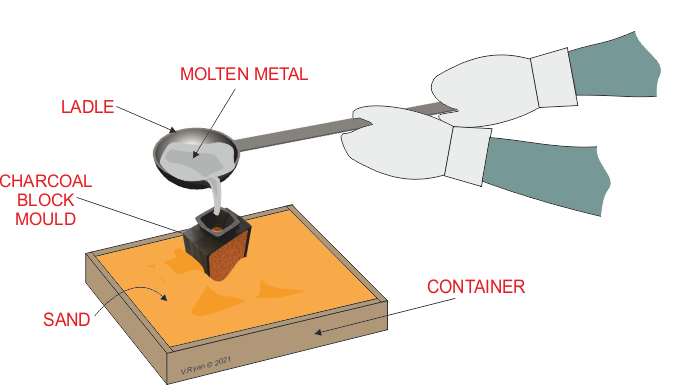

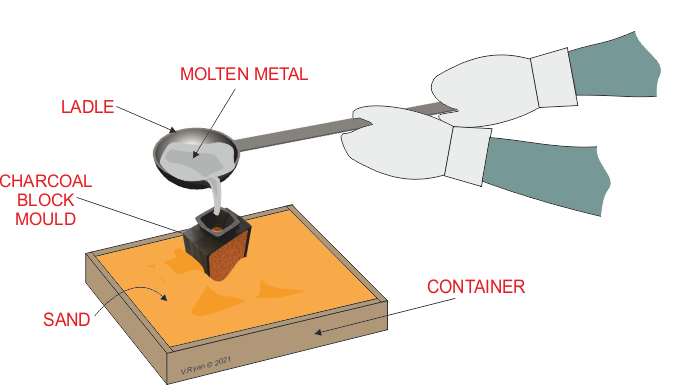

The molten metal is carefully poured into the casting boxes, via the sprue.

Note: the casting boxes are supported and held in position, by sand piled around it. Normal builders sand is ideal for this purpose. |

| |

|

| |

| After cooling, the casting boxes are split apart. The cast jewellery is removed from the delft clay and cleaned up in the usual way. The delft clay is recycled for use again. |

| |

| |

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|