V.Ryan © 2021

| CLICK HERE FOR INDEX PAGE |

| JEWELLER'S DRAW PLATES |

V.Ryan © 2021 |

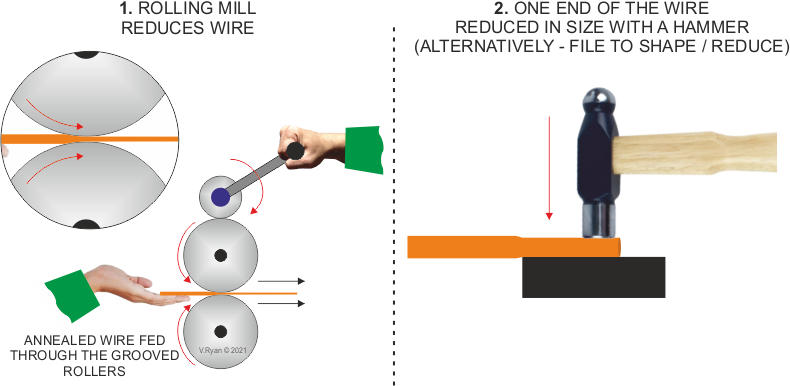

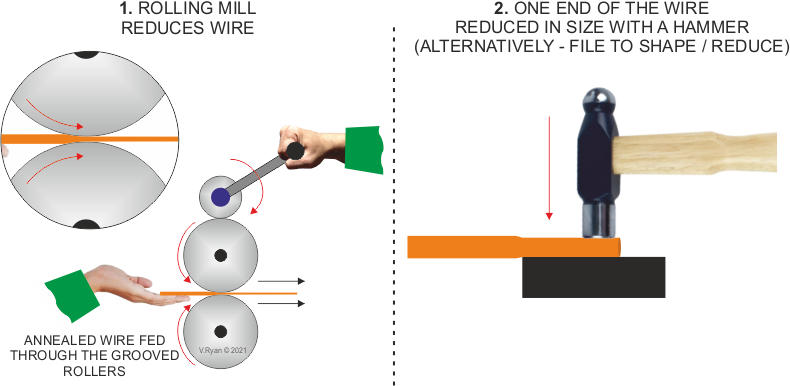

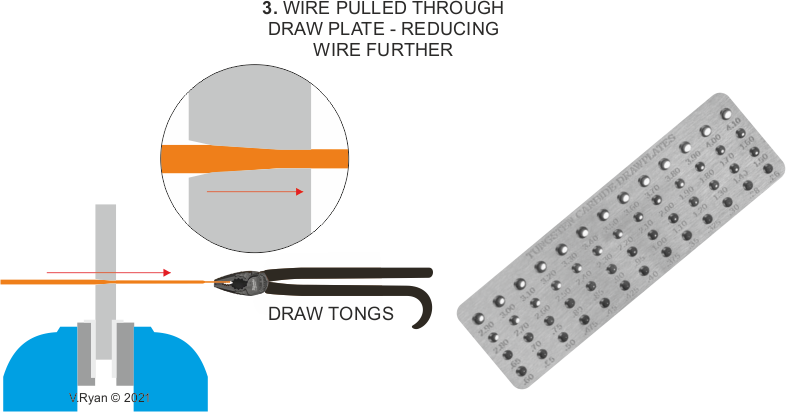

| Draw plates are made from high quality hardened steel. They are used to reduce the thickness of ‘wire’ or to change its cross-sectional shape. The wire is annealed so that it is soft and malleable. It may be necessary to feed it through the grooves of a rolling mill first, to draw it down to a reasonable size. One end of the wire is reduced by placing it on a steel plate and gently hammering it and at the same time rotating it (in place of hammering, filing will also reduce the thickness of the wire). This ensures that the end of the wire, will fit through the first selected hole, in the draw plate. |

|

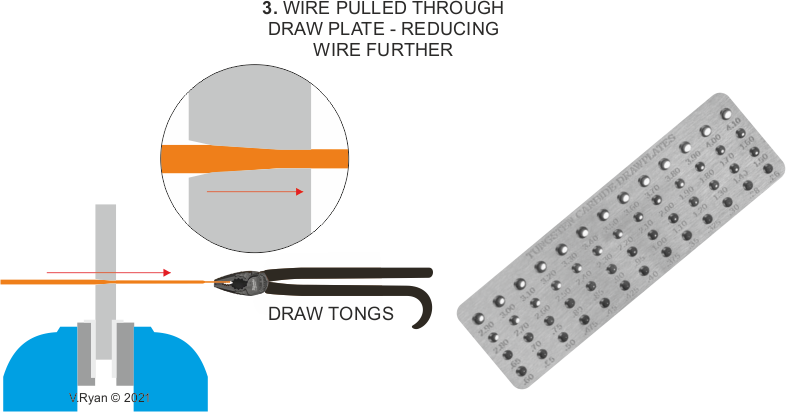

| The wire is then ‘pulled through’ a series of holes in the draw plate, each one smaller than the previous hole, until the desired diameter is reached. Draw tongs grip the wire and the user uses his /her weight to even apply force, pulling the wire through the hole.. The ‘curl’ of the draw tongs, prevent hands slipping during the drawing procedure. Bees wax / light oil / silicone lubricant, is applied to the wire. This lubricates the wire as it is drawn through the plate. |

|

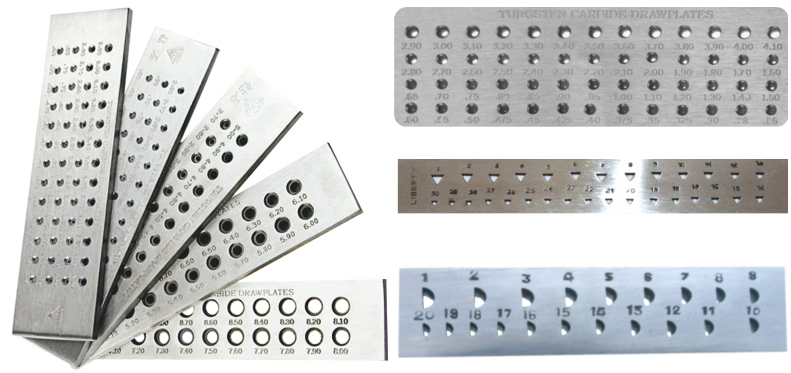

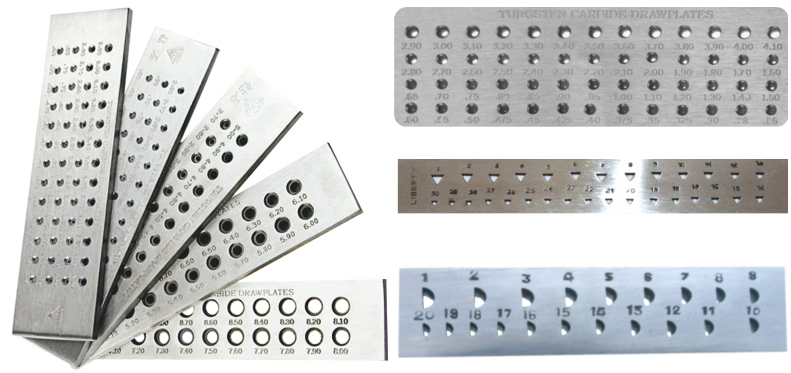

| TYPICAL DRAW PLATES |

|

| CLICK HERE FOR JEWELERY INDEX PAGE |

|