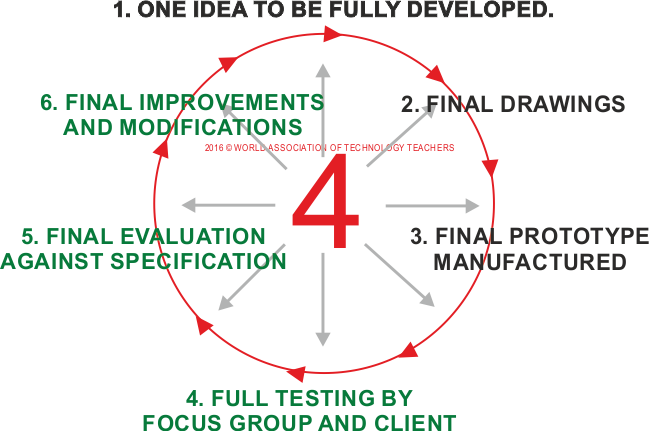

1. ONE IDEA TO BE FULLY DEVELOPED.

Develop one final idea, through model making, CAD , Sketching.

Sample Design Sheets - Final Developed Idea

2. FINAL DRAWINGS

Produce the necessary working drawings to manufacture the product, including parts lists.

Sample - Working Drawing and Isometric View

3. FINAL PROTOTYPE MANUFACTURED

Keep a photographic record of every stage of manufacture. Describe each stage of manufacture and consider how each stage can be made more efficient.

4. FULL TESTING BY FOCUS GROUP AND CLIENT

The final product should be fully tested by the client / focus group / potential customers and your self. Keep a record of all testing and suggestions.

Testing and Evaluation - Why?

Testing and Evaluation Sheet 1

Testing and Evaluation Sheet 2

5. FINAL EVALUATION AGAINST SPECIFICATION

Compare your product against the original specification. Does it meet the specification?

6. FINAL IMPROVEMENTS AND MODIFICATIONS

What future modifications have been suggested by the potential customers, focus group / client? What modifications do you think you could make to the next prototype ?