| CLICK HERE FOR INDEX PAGE |

| |

| BOBBIN SANDER / OSCILLATING SANDER |

V.Ryan © 2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

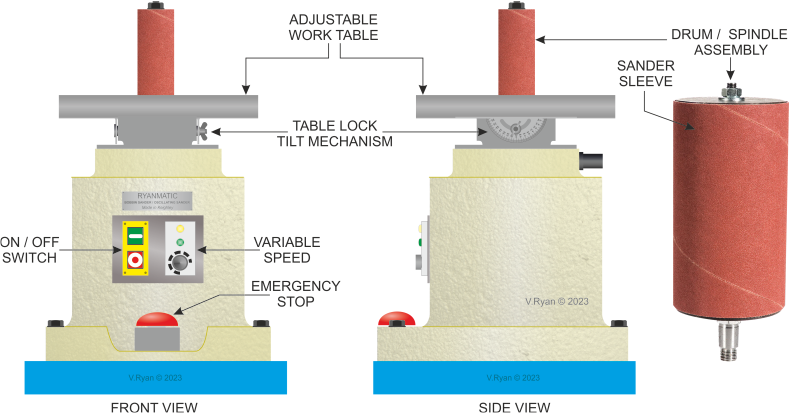

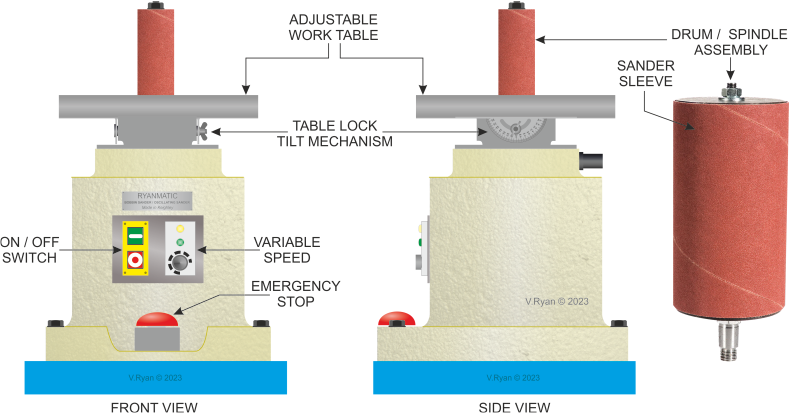

A Bobin Sander is a table top sanding machine, for smoothing edges. The spindle rotates at high speed and also oscillates up and down, making it ideal for sanding curved surfaces. It is perfect for ‘tight’ curves, which cannot be accessed by a normal sanding disk or belt sander.

The drum / spondle and sanding sleeves (see diagram below) , are supplied in a range of sizes. |

| |

|

| |

|

|

| |

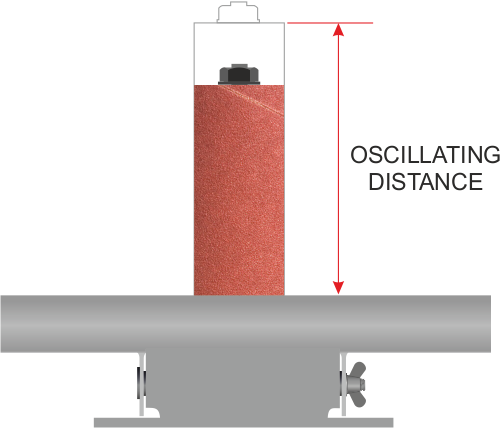

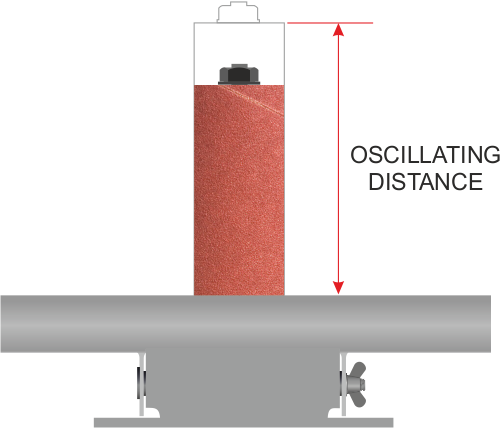

| The bobbin sander’s spindle can vary in height and the distance it oscillates (up and down). The distance of oscillation, to some extent, determines the thickness of materials that can be sanded. |

| |

|

| |

|

| |

| REPLACING THE SLEEVE |

| |

| The sanding sleeve will eventually need replacing, as it wears down. To replace the sleeve - loosen the top nut and remove the old sleeve. Put the new sleeve in position and tighten the top nut. |

| |

|

| |

|

|

| |

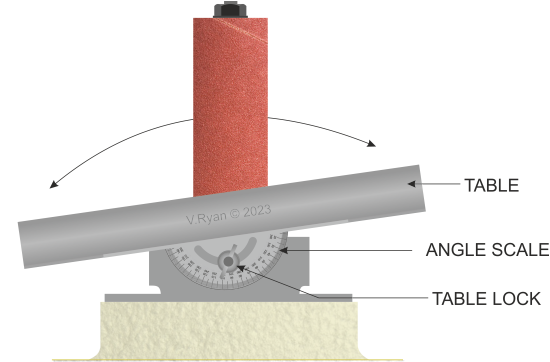

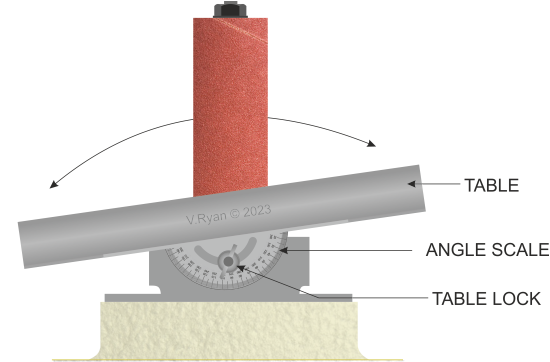

| ADJUSTING THE TABLE ANGLE |

| |

The table can be adjusted to a variety of angles. This is achieved by loosening the table lock, altering the angle according to the scale and re-tightening the table lock.

Work can be sanded to an accurately angle, producing an incline or a chamfered / bevelled edge. |

| |

|

| |

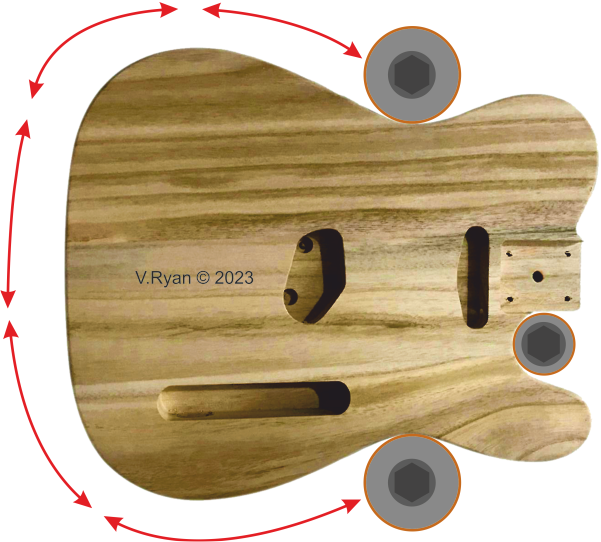

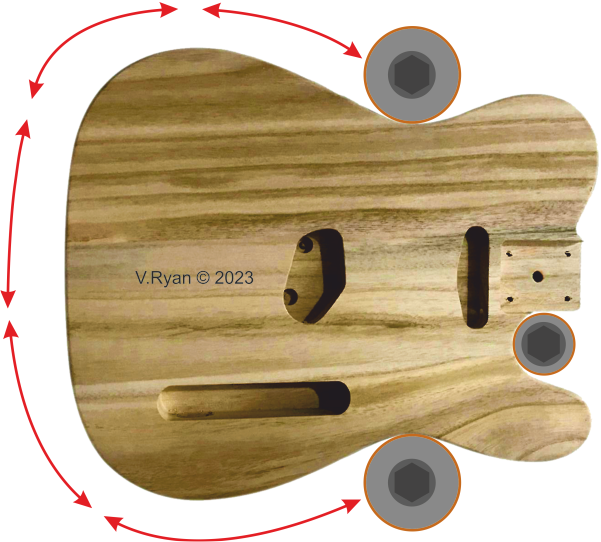

| EXAMPLE USE OF A BOBBIIN SANDER |

| |

| The internal curves of the body of a guitar, can be sanded efficiently and easily with a bobbin sander. |

| |

|

| |

| When changing the drum and replacing it with a different size, great care must be taken to replace the insert. The insert must allow enough clearance between itself and the rotating and oscillating drum, but not so much as to leave a dangerous gap. |

| |

|

| |

|

|

| |

Bobbin sanders should be bolted to a robust table / workbench. This is not only a safety measure, but it also ensures a reduction in vibration caused by the machine as it is used.

Extraction is essential because of the build up of dust during the sanding process. A dust mask is also advisable.

When in use, the work is presented to the bobbin and constantly moved to ensure the edge is not burnt / overheats. |

| |

|

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|