| CLICK HERE FOR INDEX PAGE |

| |

| THE BAND SAW BLADE |

V.Ryan © 2022 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

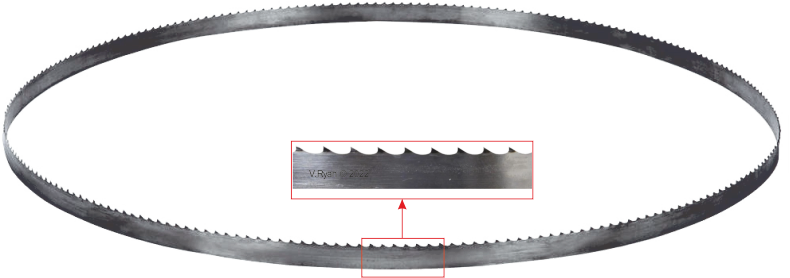

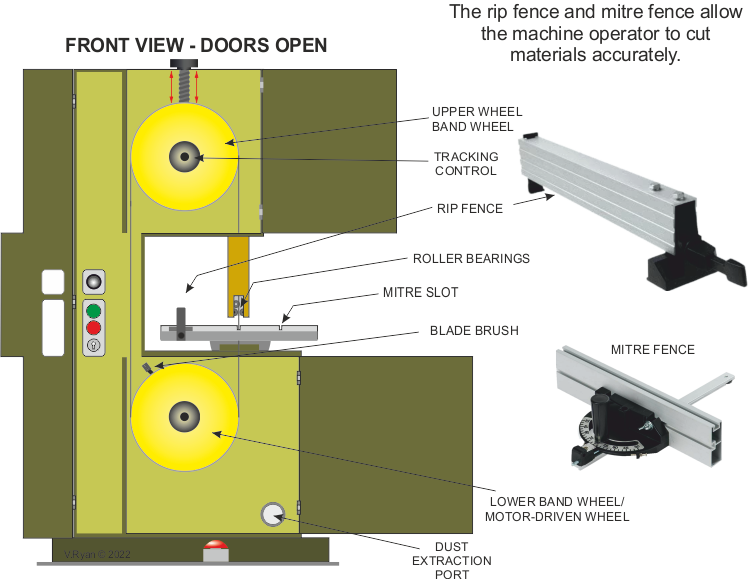

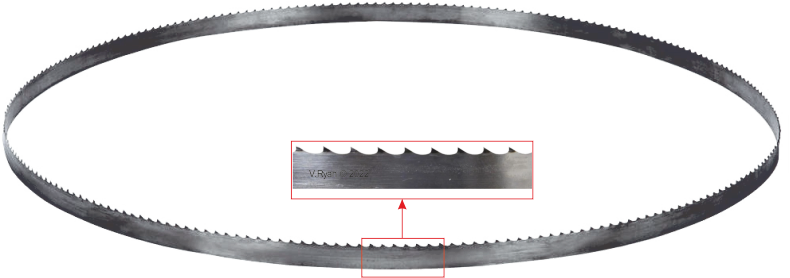

The band saw blade is in the form of a continuos loop. When is it fitted to the band saw, it runs round two band wheels (in some machines there are three wheels). The bottom wheel is driven be a motor which pulls the blade round, during the cutting procedure. The teeth of the blade point downwards.

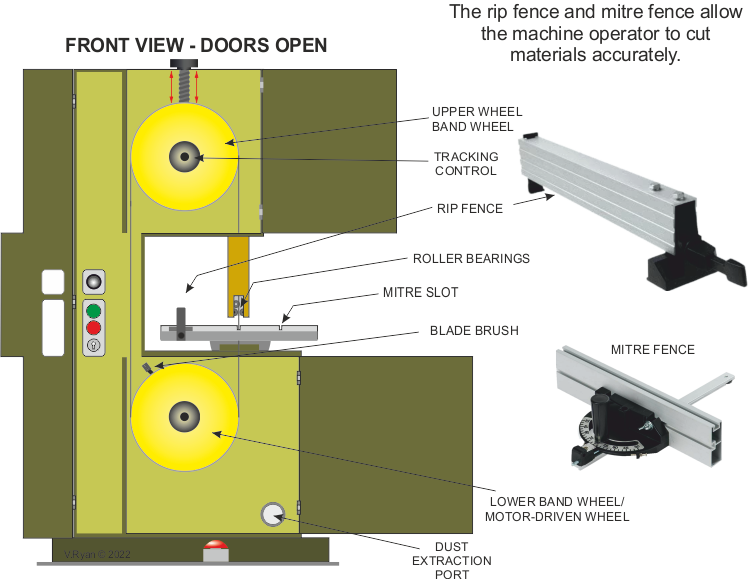

The diagram of the band saw below, shows the upper, lower and side doors open. The bland can be seen, fitted to the band wheels. When the doors are open, it is impossible to turn on the power. This is an important safety feature. The doors must be closed, before the machine can be turned on. |

| |

|

| |

|

|

| |

|

| |

| |

|

|

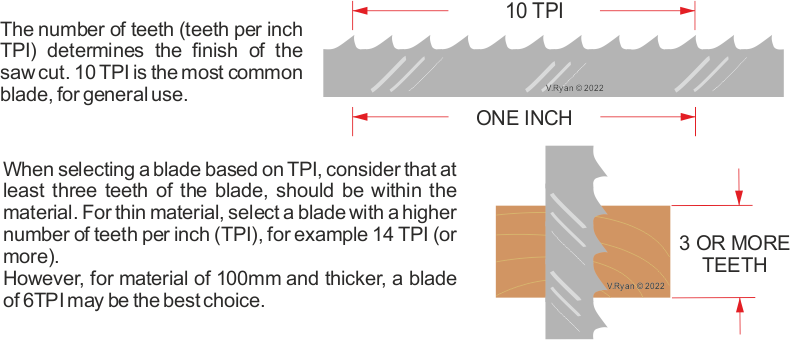

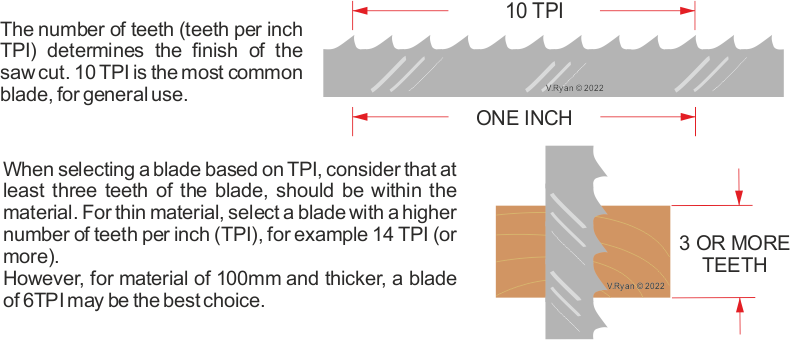

Most people use standard / regular band saw blades. However, with experience, a band saw operator will select the type of blade, to suit a particular material or the type of cutting to be performed.

Band saw blades are made from flexible steel, with the teeth being hardened (heat treated) and toughened, to maintain their cutting sharp edge. |

| |

|

| |

|

|

| |

| BAND SAW TOOTH TYPES |

| |

|

|

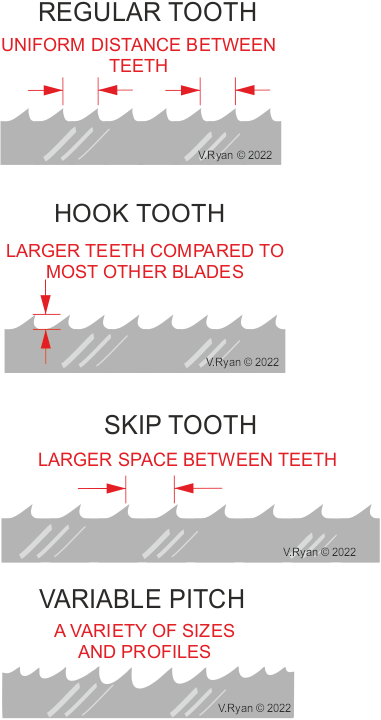

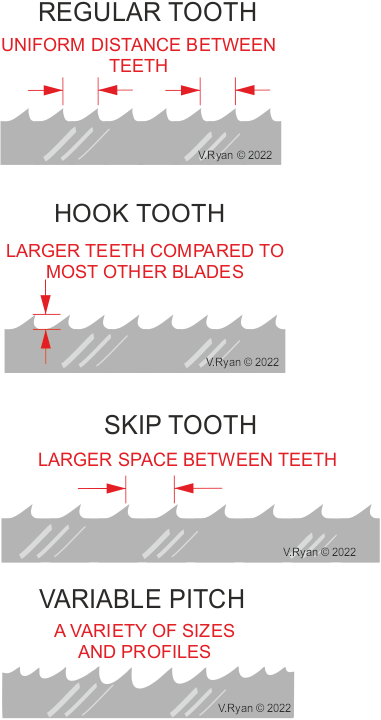

Regular Tooth: This is a common, standard blade, producing a fine cut on woods. Most band saws are fitted with this type of blade.

Hook Tooth: These have larger teeth, with a ‘hooked’ profile, enabling a more aggressive cut. Normally for thicker sections of hard wood, plastic. For prolonged, rough cutting.

SKIP TOOTH: Ideal for plastics and materials, that are likely to clogg / jam regular blades. The increased distance between each tooth, means that jamming of the blade is less likely.

VARIABLE PITCH: This blade is composed of teeth of different sizes. This blades is ideal when cutting curves.

|

| |

| BAND SAW BLADE SET |

| |

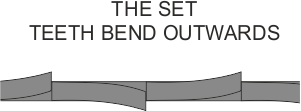

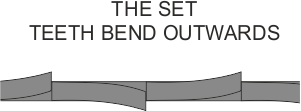

| The teeth of a band saw blade are bent outwards from the band of the blade (see opposite). This is called the ‘set’.The ‘set’ gives the blade clearance and reduces friction, as the blade cuts through the material. The ‘set’ of the teeth help prevent jamming or over heating of the blade, which could lead to it breaking / snapping / jamming. The ‘set’ of a blade produces the clearance and allows for cutting curves. |

|

|

| |

| With a standard set, the teeth are bent alternatively to the left / right. This is probably the most common type of blade used on band saws. |

| |

|

| |

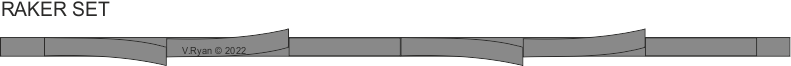

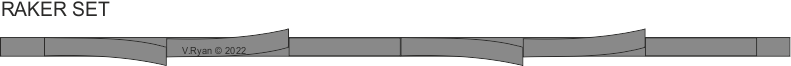

| The raker set have two sets of teeth, separated by an un-set tooth. This pattern continues round the entire blade. This is ideal for cutting curves. |

| |

|

| |

| The wavy set is ideal for cutting thin boards. Notice that the profile of the teeth, look like waves. |

| |

|

| |

| The alternative set is very similar to the standard set, although the offset of the teeth is less profound than standard set blades. |

| |

|

| |

|

|

| |

| BAND SAW BLADE WIDTH |

| |

| Band saw blades are available in a number of widths. Wider blades (e.g. 20mm) are better for cutting straight lines, as they are less likely to bend or be deflected. However, wider blades tend to cut restricted / limited curves. When cutting tight curves, a thin blade is the best choice (e.g. 6mm). Machine operators try to reduce the number of times the blade needs changing, as this is time consuming. Therefore, when selecting a blade, try to keep one that is capable fo cutting straight lines and general curves. It is worth noting, that thinner blades are more likely to wear and break. |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|