| CLICK HERE FOR INDEX PAGE | |

| DISK SANDER - 2 | |

| V. Ryan © 2007 - 2021 | |

| This disk sander is being used in an unsafe manner. Identify all the areas that show DANGEROUS use of the machine. One area has been identified for you. | |

| 1. The surround / guard of the rotating disk is broken. This means the disk is exposed and fingers / hands are in danger. The guard should cover the right hand side of the rotating abrasive disk. 2. The machine operator is not wearing his goggles properly. He has then ‘perched’ on his forehead. His eyes are in danger from flying dust and particles. 3. The gap between the rotating sanding disk and the table is far too great. The machine operators fingers and the material, could easily be dragged down the gap. This is a very serious lapse in safety. 4. The machine operator is breathing in dangerous dust. Dust is dangerous and a dust mask should be worn and dust extractor used. 5. There is a ‘crack’ in the sander disks table. This will eventually lead to the table snapping entirely. This is a potentially serious accident, waiting to happen. The machine operator should shut down the machine and report the damage to his teacher. 6. The machine operator is not holding the material with both hands. The work is not under his complete control. Both hands must control and guide the work. 7. The dust extractor is not working. The extraction tube is disconnected. This means that all the dust is being ‘pumped’ into the atmosphere and will be breathed in by the pupils in the workshop, especially the machine operator. 8. The sanding disk is not bolted down to the bench. A G-cramp has been used to hold it in position. This is not strong enough and the cramp will vibrate loose. The whole machine could topple off the bench. Machines of this type, must always be permanently bolted down. 9. The foot switch is broken and probably does not work. In an emergency, this switch will be vital. 10. The machine operator is wearing training shoes. He should be wearing leather shoes / safety shoes. 11. The machine operator is not wearing an overall / apron. His clothing (shirt and tie) is loose and could easily be caught by the rotating sanding disk. He could find himself dragged into the machine. 12. Waste wood / material has been left on the bench, making the area untidy. If the waste builds up, it will interfere with the use of the sanding disk. |

|

|

|

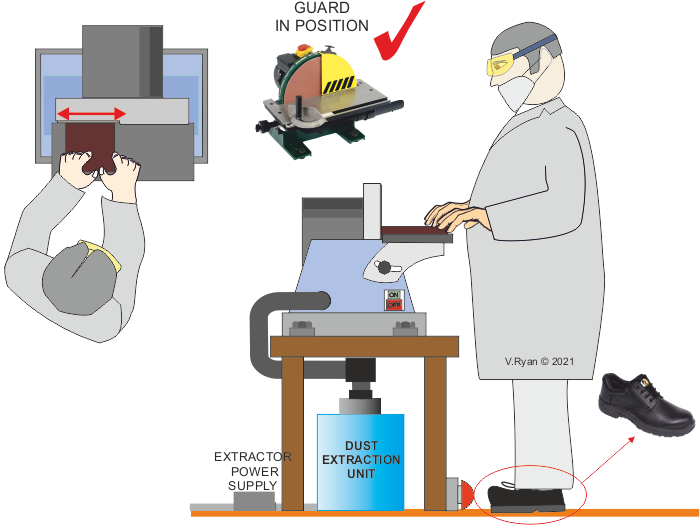

| This disk sander is being used safely. Identify all the areas that show SAFE use of the machine. One area has been identified for you. | |

| 1. Always wear goggles to protect eyes. 2. The extractor is on, extracting dangerous dust produced by sanding the material. Your teacher may advise you to wear a dust mask. This depends on the quality / efficiency of the extraction unit. 3. Only sand to smooth the edge of material. Never, use a sander to remove large amounts of material (a fretsaw or coping saw / hand tool, should be used to shape the material first). 4. Use both hands to control the movement of the material. The material should be moved gently from side to side, so that half the width of the abrasive disk is used. If the material is not moved side to side, one area of the disk will be worn down very quickly. 5. The sanding disk abrasive, should be replaced regularly. A ‘worn’ disk may lead to the machine operator, pressing the material against the disk, with too much force, compensating for the lack of abrasion. Pressing the material with too much force, could easily lead to hands slipping on to the abrasive disk, leading to a serious injury. 6. Wear an apron / overall. This will hold back loose clothing such as a tie. An apron / overall will help keep your clothes clean. 7. Wear safety shoes / leather shoes. 8. Ensure that the sanding area is free of dust and debris, before it is used. Clear away any material left on the sanding table and bench. 9. This disk sander has the correct guard, covering the right hand side of the abrasive disk. |

|

|

|

|

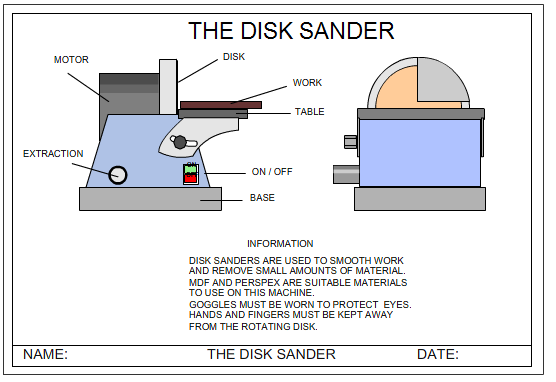

Produce an information sheet on the disk sander similar to the one seen below. You may wish to draw a sander seen in your workshop rather than the sample or to include more health and safety information rather than general information. |

|

|

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | |