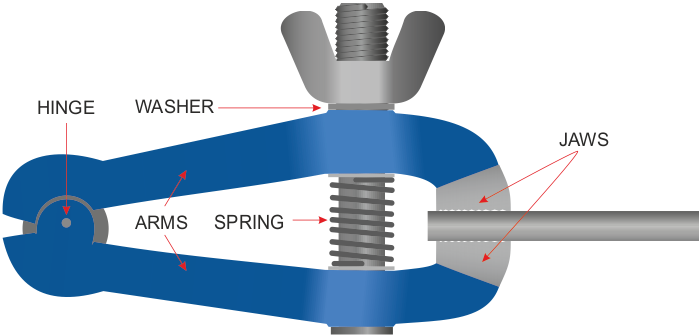

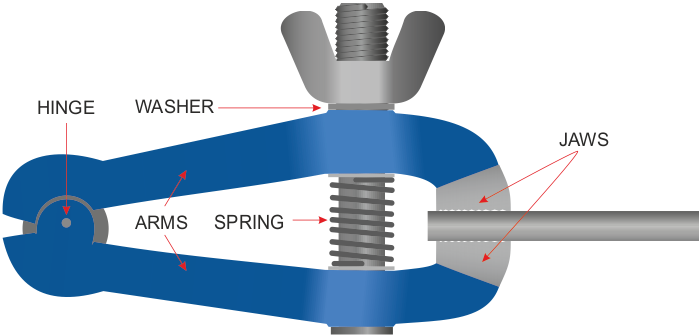

Quality hand vices are manufactured from cast iron, with machined jaws, hardened and tempered.

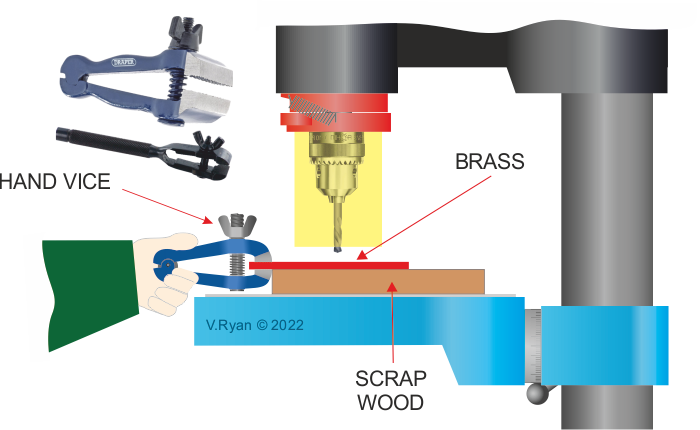

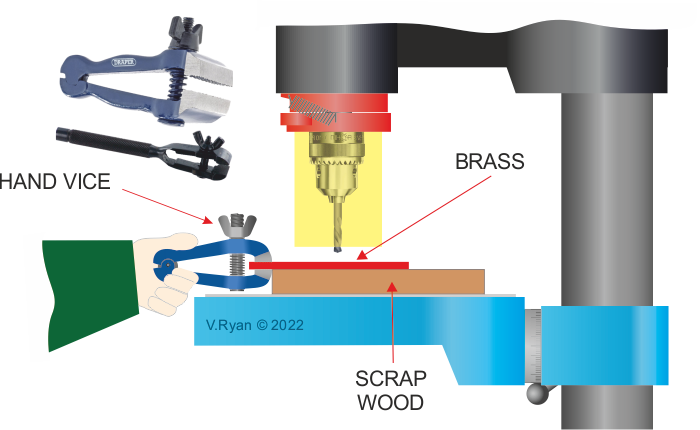

The sheet metal is held firmly in the hand vice. It also rests on scrap wood, on the table of the drilling machine.

| CLICK HERE FOR INDEX PAGE | ||

| THE HAND VICE | ||

| V.Ryan © 2019-2022 | ||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | ||

| A hand vice is extremely useful, when holding sheet metal and thin metal sections. This is especially the case when drilling. A machine vice, is not always the best way of holding materials. Sheet metal / thin sections can ‘spin’ out of machine vice when being drilled, because there is not enough surface area to hold it securely between the jaws. This is dangerous, because spinning sheet metal has the potential to cause serious injury. However, a hand vice is designed for holding thinner materials, with the jaws clamping the top and bottom surfaces (not the edges). Quality hand vices are manufactured from cast iron, with machined jaws, hardened and tempered. |

|

|

| To operate the hand vice, loosen the wingnut and the arms will spring apart. Place the metal between the jaws and tighten the wingnut, securing the metal between the jaws. | ||

|

||

|

||

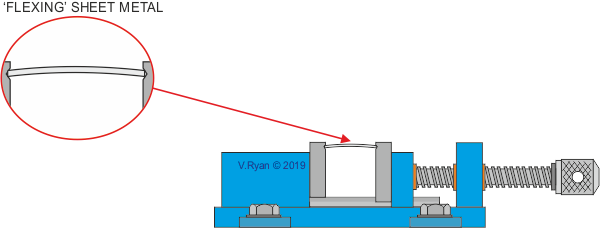

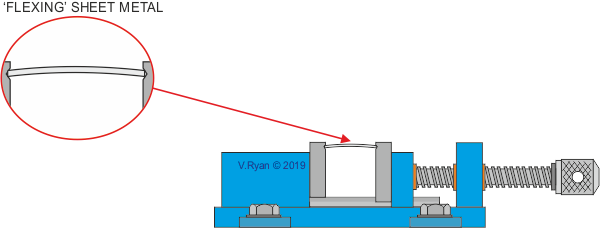

| This diagram below, clearly demonstrates, why a machine vice is not suitable for holding sheet metal whilst drilling. The magnified view shows, the sheet metal bending under pressure, applied by tightening the vice. If drilling goes ahead, the drill bit will slip from the correct position and it is likely that the metal will spin ‘dangerously’ out of the vice. | ||

|

||

| The hand vice, shown below, is one safe way of holding the sheet metal whilst drilling. The sheet metal is held firmly in the hand vice. It also rests on scrap wood, on the table of the drilling machine. |

||

|

||

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | ||

|

||