V.Ryan © 2022

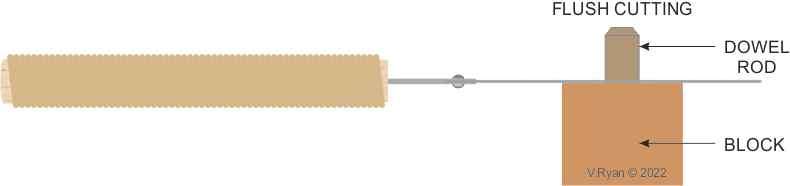

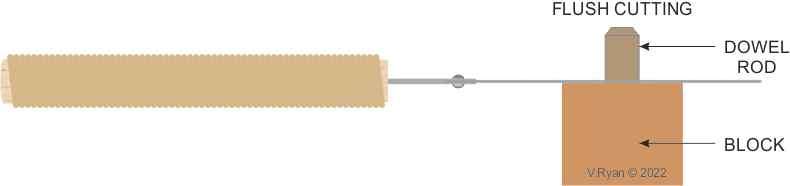

An ‘Hugihiki’, is a more flexible version of this type of saw. It is specifically used for flush cutting dowels.

| CLICK HERE FOR INDEX PAGE |

| JAPANESE SAWS |

V.Ryan © 2022 |

| PDF FILE - CLICK HERE FOR PRINTABE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

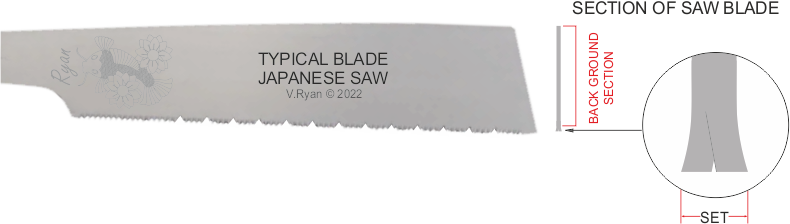

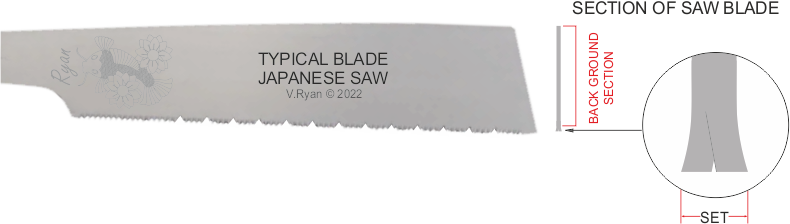

| Japanese saws are not only beautifully designed, but they are also extremely useful and practical. These saws cut on the back stroke, unlike European tenon and dovetail saws, which cut when pushed forward. They have a major advantage, in that the teeth have a fine set, which leaves a thin kerf (saw groove). The blades are usually taper ground. This means that the blade is thicker along its cutting edge, compared to its back edge. A blade that is taper ground, needs less ‘set’ to its teeth, hence a finer cut. Taper ground also means that there is less friction when sawing. |

|

| KATABA |

| The Kataba saw has a range of general uses, similar to the western panel saw. It does not have a supporting ‘back’ (as seen with a tenon saw or dovetail saw) and has a single cutting side. The saw will have either, teeth for crosscutting or ripping along the grain, producing a sharp, rapid cut. The blades are from 250mm to 330mm in length. Cabinet makers tend to prefer the smaller length blades, whilst general carpenters tend towards the longer blade. |

|

| RYOBA |

|

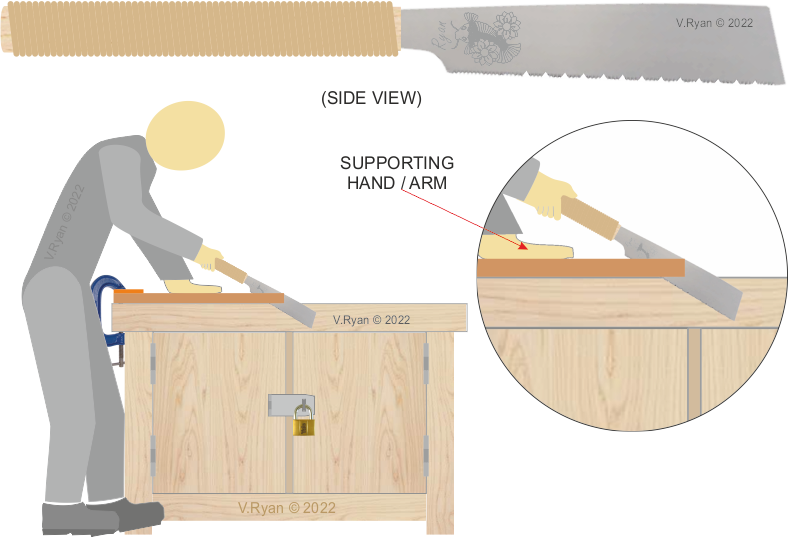

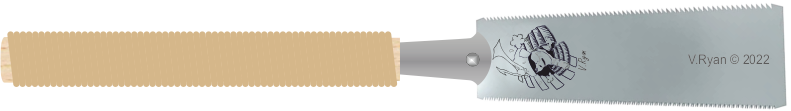

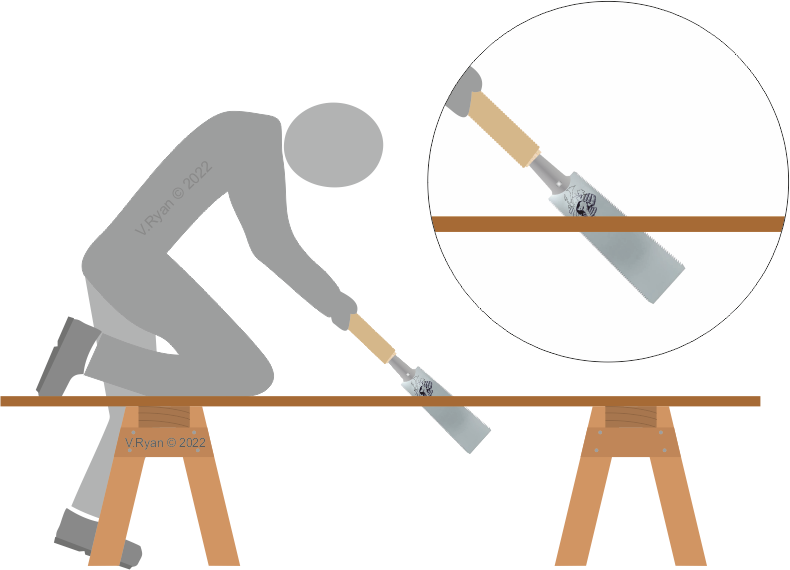

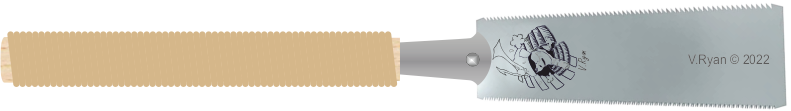

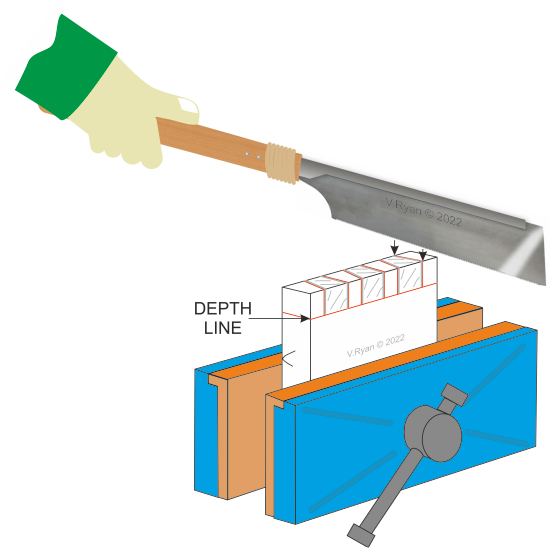

| One side of the blade is for ‘ripping’ and the other for crosscutting. The larger teeth are the ripping teeth. The teeth point towards the handle, due to the saw being called a ‘pull saw’. The blade is quite flexible, because it does not have a back / support. A ‘back’ on this saw would interfere with ripping and crosscutting. This saw is also good for ‘flush cutting’ (seen below). |

| To remove the excess dowel from the block, the blade is placed ‘flat’ on the wood. An ‘Hugihiki’, is a more flexible version of this type of saw. It is specifically used for flush cutting dowels. |

|

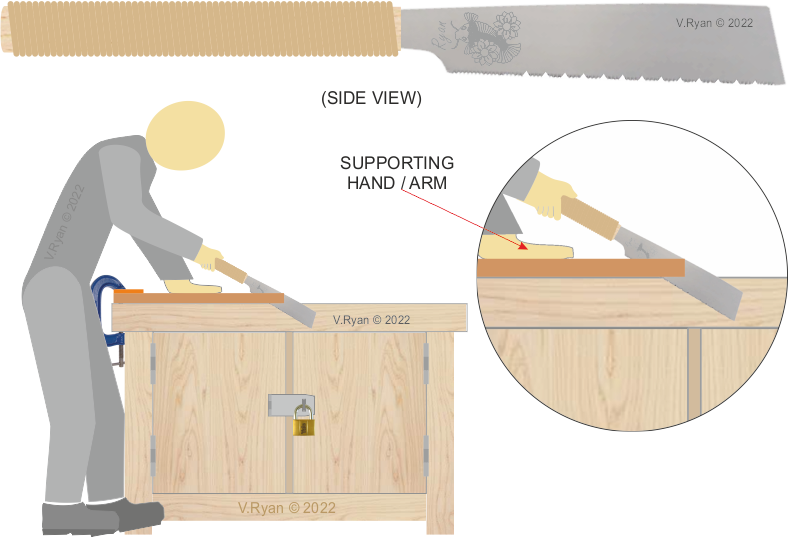

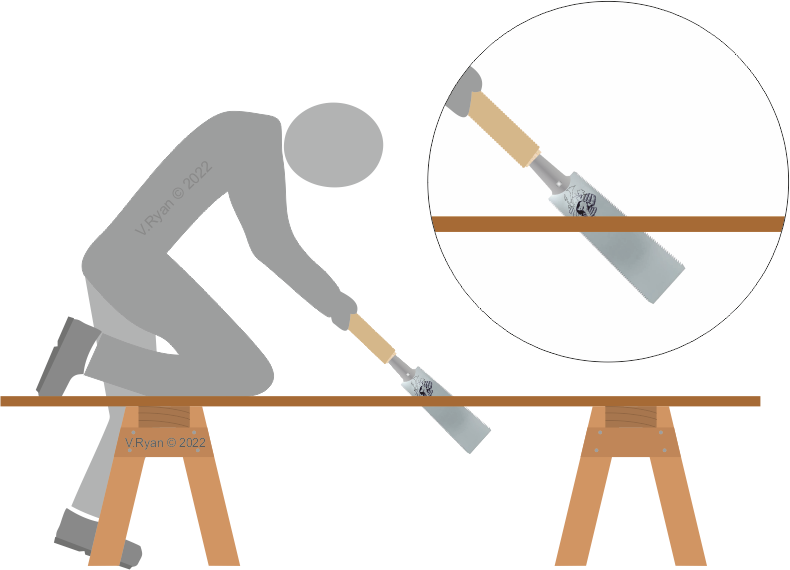

| Below, the ripsaw side of the ryoba saw, is being used for cutting along the grain (ripping). |

|

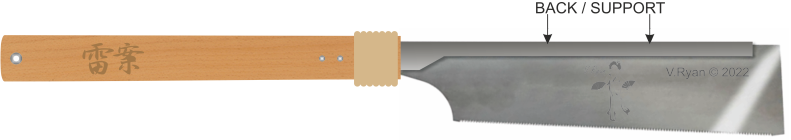

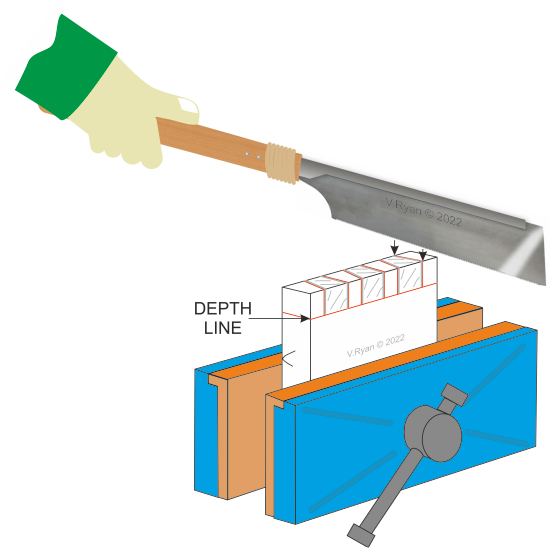

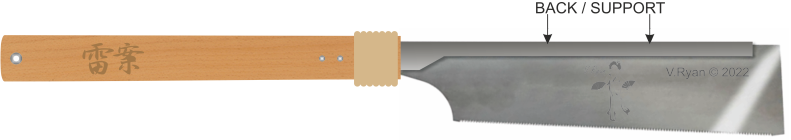

| DOZUKI |

|

| The support / back of the saw blade, prevents it from bending. The blade is usually thinner than the blade of the Ryoba saw and the teeth are finer. This saw is ideal for accurate joint work, such as dovetails. |

|

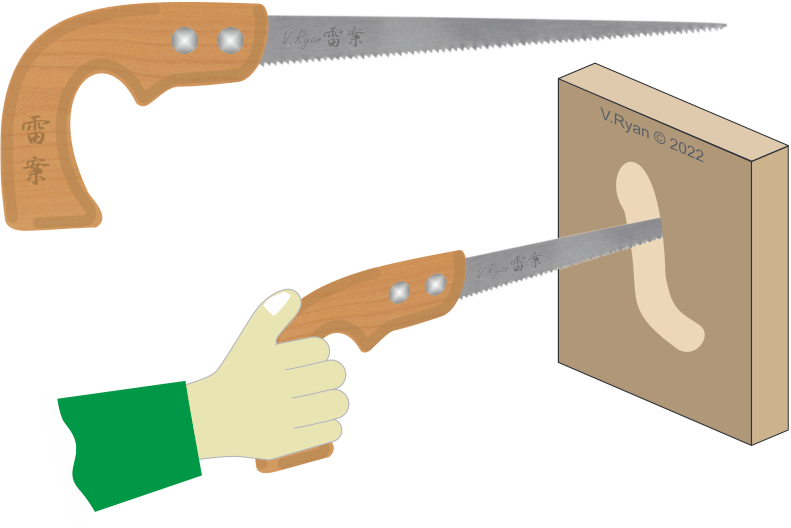

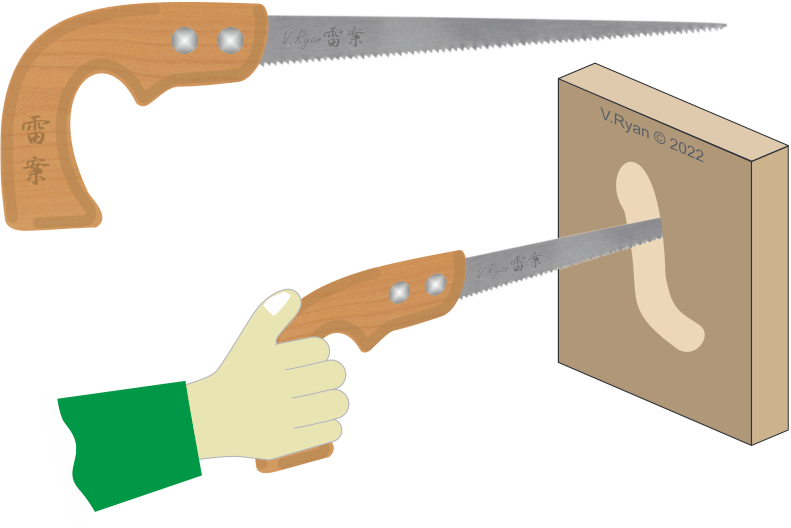

| MOWASHIBIKI |

| The mowashibiki saw is similar to a Western / European pad saw. It is used to cut awkward shapes, as seen opposite. It has a thin tapering blade, ideal for difficult curves. |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|