| CLICK HERE FOR INDEX PAGE |

| |

| USING SILICONE RUBBER FOR LOST WAX CASTING |

V.Ryan © 2020 - 2021 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| PowerPoint Version - CLICK HERE FOR WORKSHEET |

| |

An alternative casting technique, is to use ‘silicone rubber’ in the place of ‘investment’. This surrounds the wax model, producing the mould.

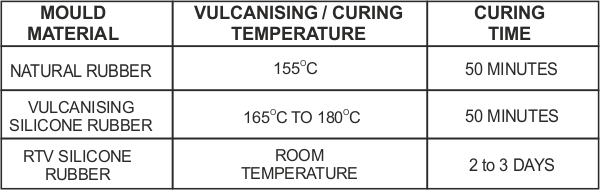

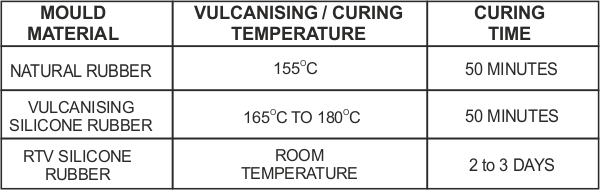

There are three types of rubber mould materials: natural rubber, vulcanizing silicone rubbers, and room temperature vulcanizing (RTV).

The RTV is a two part mix, which cures at room temperature, over a couple of days. The other two ‘rubber’ materials require heat at a precise temperature, to ensure proper curing. |

| |

|

|

| |

| USING RTV |

| |

| 1. Mix silcone rubber with a catalyst, to the exact proportions as stated by the manufacturer / supplier. |

| |

|

| |

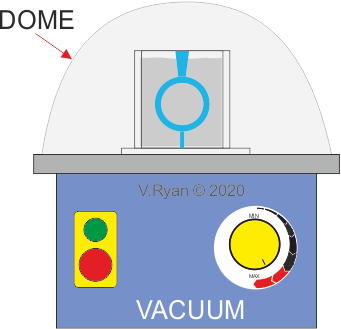

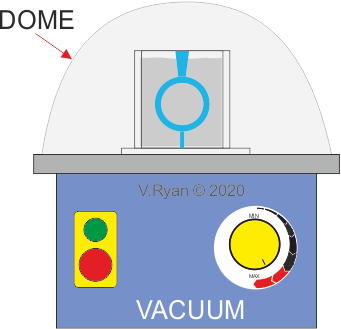

| 2. Place the silicone rubber mixture in a vacuum for 3 minutes, to remove air. The mixture expands as it ‘boils up’ (bubbles), filling the bowl. Then it returns to its original height in the container. |

|

|

| |

|

|

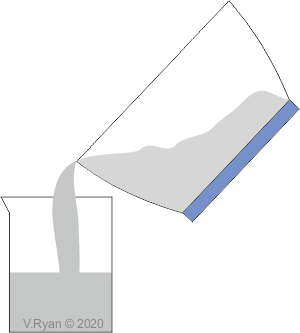

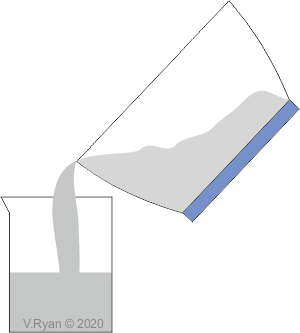

| 3. The silicone rubber is poured into a container / jug. |

|

|

| |

|

|

| 4. Pour the mixture into the mould. |

|

|

| |

|

|

|

|

| |

|

|

| 5. Place back into the vacuum. It will boil up / bubble again and then return to its original height. |

|

|

| |

|

|

| 6. Turn off the vacuum and leave the mould inside the dome for at least 24 hours. The reason for this, is to keep the mould away from moisture in the air, as the RTV rubber cures. Moisture tends to degrade this type of rubber mould. |

|

|

| |

|

|

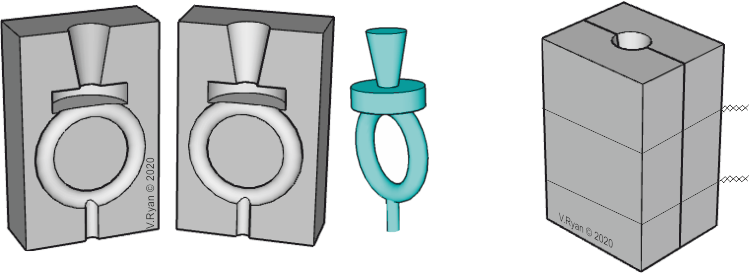

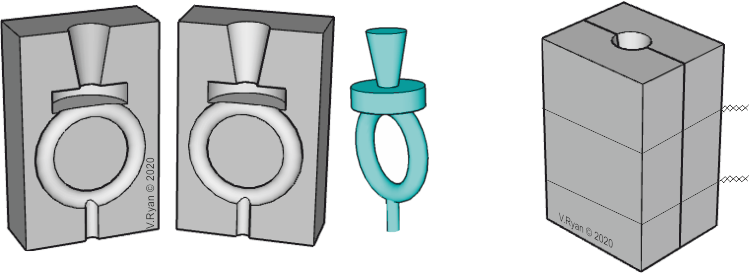

| 7. Great care must now be taken, to cut the mould accurately in two, using a craft knife. The wax model can then be removed, leaving the cavity. The two halves are wired or carefully clamped together, ready for accepting molten metal. |

| |

|

| |

|

|

| |

| CASTING PROCEDURE |

| |

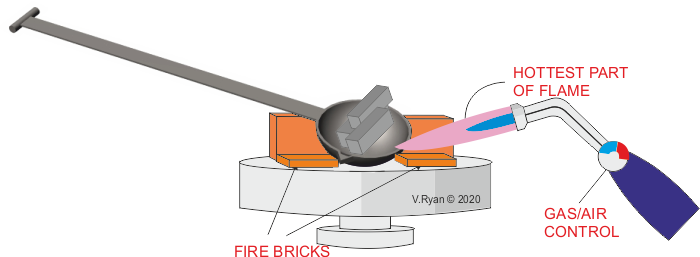

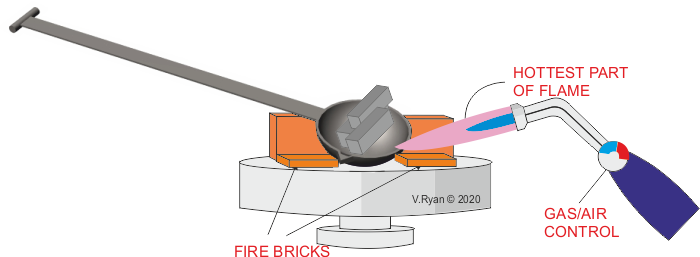

| The diagram below shows pieces of pewter cut to a size, suitable for heating in a ladle. Metals such as bronze, brass. silver and other precious metals, can be used. Fire bricks are arranged around the bowl of the ladle, so that the heat from the brazing torch flame, is reflected back towards the pewter. As the temperature rises, the pewter begins to become molten and quite quickly forms a liquid. |

| |

|

| |

| The molten pewter is carefully poured into the mould. It is important that the flask is stood in sand, in case any of the molten metal runs down the sides. If this happens the molten metal will simply stay on the surface of the sand and cool down. The flask should never be placed on a cold surface. If molten metal comes in contact with a cold surface it will ‘splatter’ violently. Anyone close to the area will be in serious danger. |

| |

|

| |

| The flask and its contents should be allowed to cool. This may take a couple of hours, depending on the metal being cast. The mould is broken apart and the cast product taken out. The sprues are removed (this metal can be recycled) and the product is finished, using files and appropriate finishing techniques. |

| |

|

| |

| RUBBER / SILICONE MOULD MATERIALS |

| |

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|