| CLICK HERE FOR INDEX PAGE |

| |

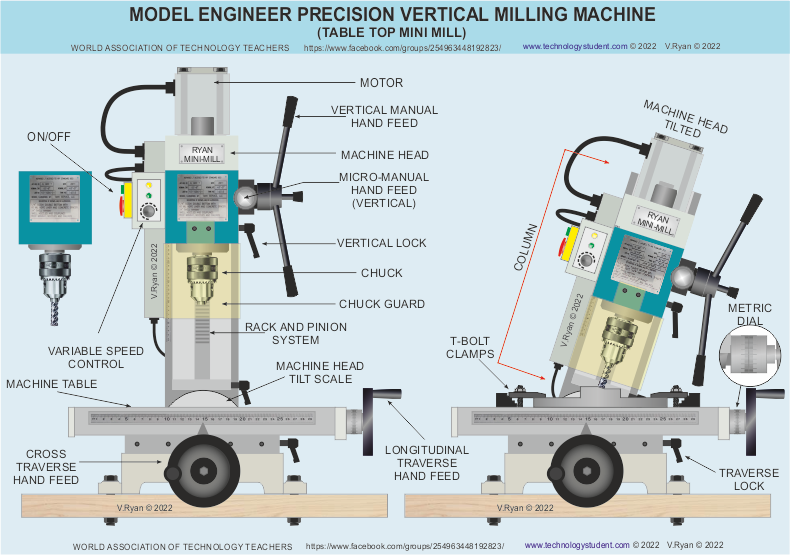

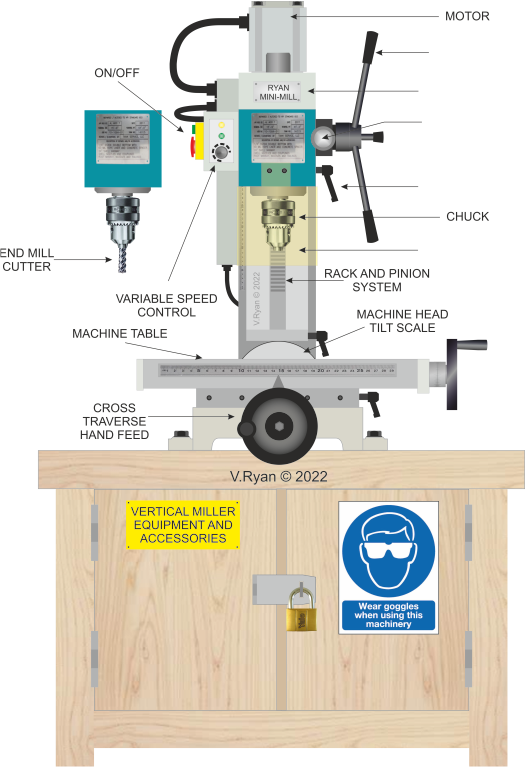

| Model Engineer Precision Vertical Milling Machine |

V.Ryan © 2022 |

| |

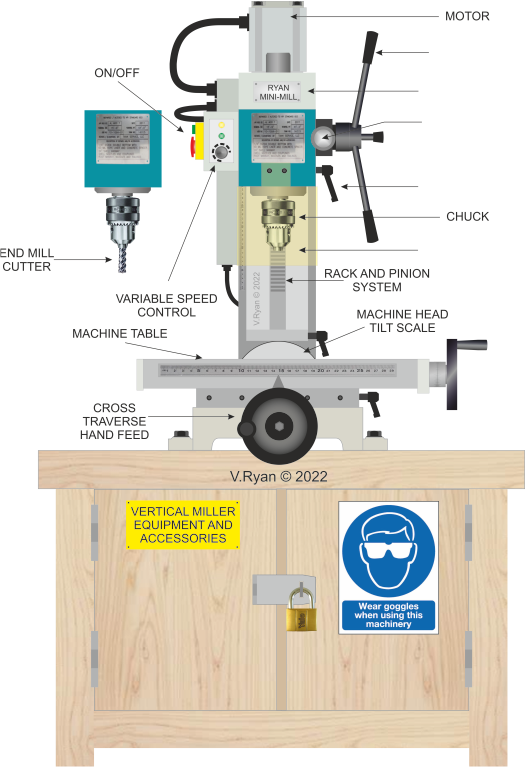

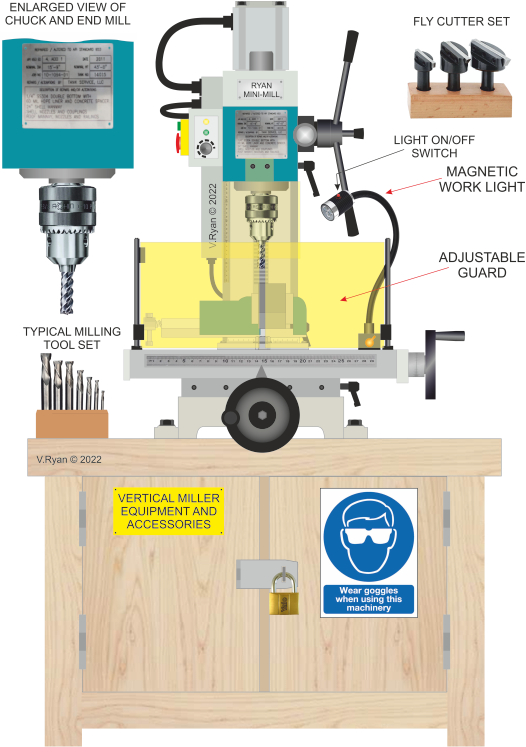

| This vertical milling machine, is every bit as functional, as a full sized version, except it is smaller and fits on a bench top. It has all the functions of the larger version, but has a limited to the size of material that can be machined.. It is an ideal miller for precision model makers and for those learning to use a vertical miller. The cost of one of these millers, is normally much less than a full sized version. It has all the accuracy expected of a precision machine. Some schools and colleges prefer to train students on the smaller version, due the the costs involved. |

| |

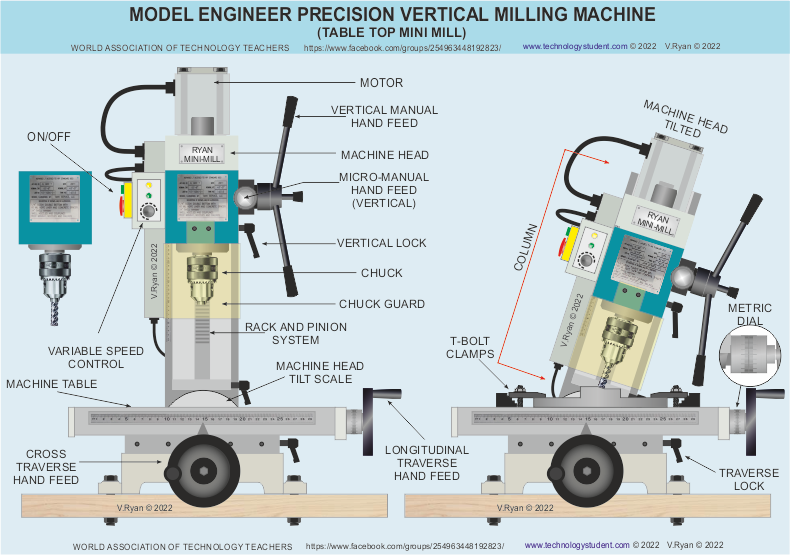

MODEL ENGINEER PRECISION VERTICAL MILLING MACHINE

(Adjustable guards removed for ease of viewing) |

| |

|

| |

|

|

| |

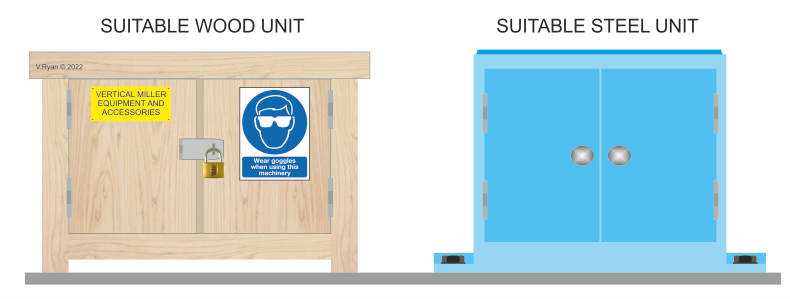

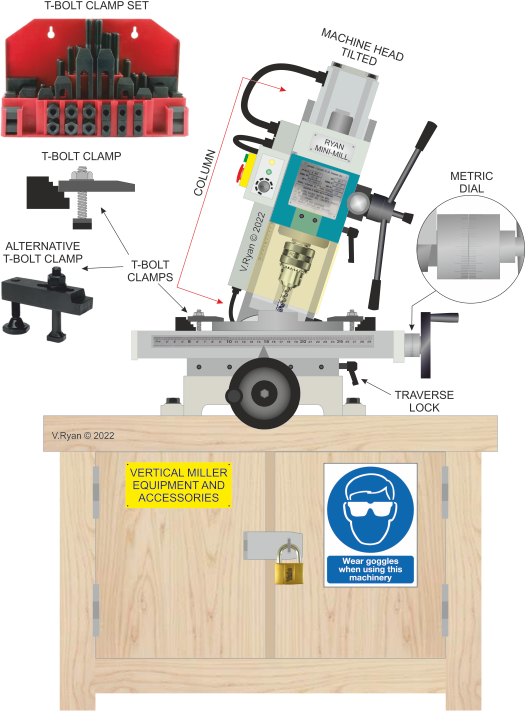

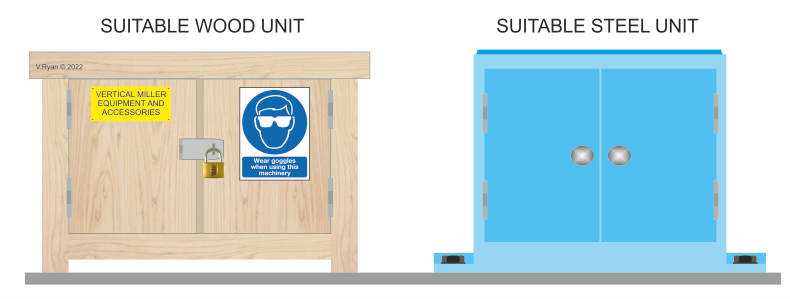

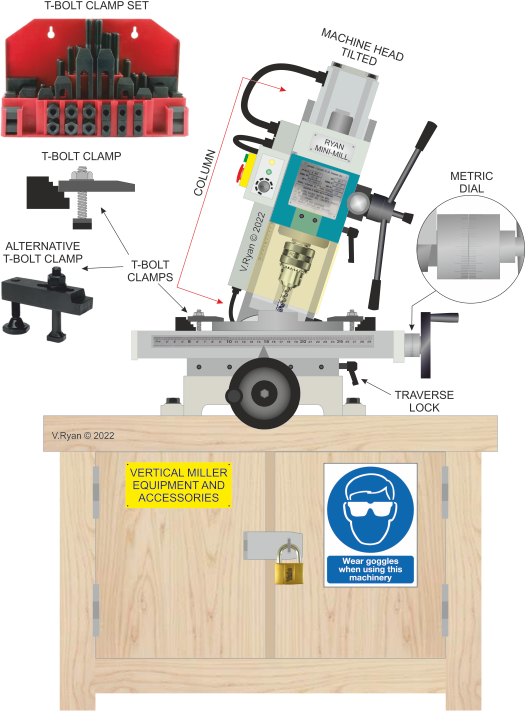

| BENCH / CABINET UNITS |

| |

| The mini miller must be secured to a substantial bench, with four bolts. It is extremely important that the miller is stable and that the bench it sits on is strong and able to absorb the vibration of the machine, as it cuts through metal. All too often the bench is over looked, when purchasing a miller. A table top mini miller, must not be placed on any bench or cabinet. A specialist bench are should be used. |

| |

|

| |

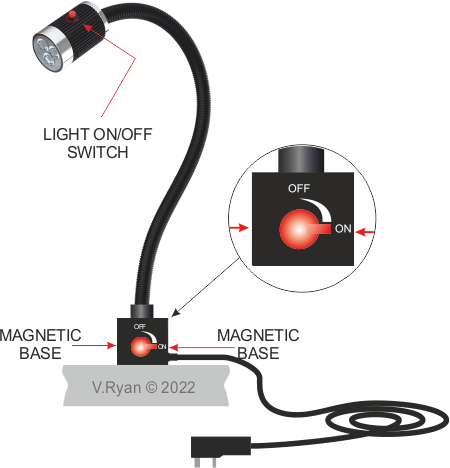

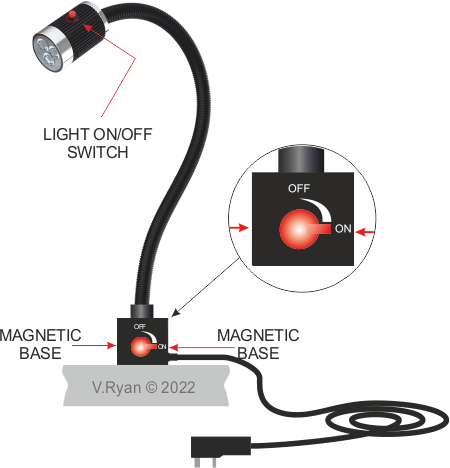

| MAGNETIC WORK LIGHT |

| |

One essential accessory is a magnetic work light. This can be positioned in a suitable position, on the machine table and provides light, so that the machining area is illuminated. The light has a magnetic base. When a switch is in the ‘on’ position, the base becomes magnetic and the work light stays in position. When the switch is in the ‘off’ position, the base is no longer magnetic and the work light can be moved.

The LED light source has high luminous efficiency and is bright, with low power consumption, generating little heat in the illuminated work area.

|

| |

|

| |

|

|

| |

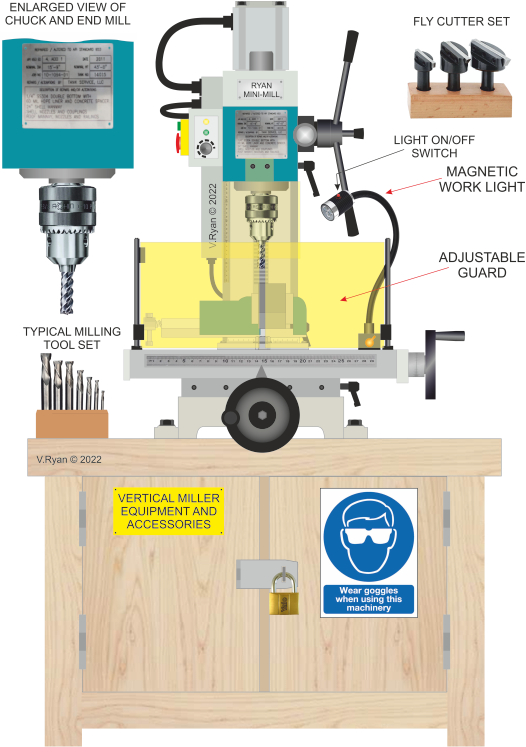

| ADJUSTABLE GUARDS |

| |

| Vertical milling machines must be operated, with the correct type of guard in position. Guards tend to be adjustable, so that they will ‘secure’ the workspace, accommodating material of a variety of sizes and shapes. Guards protect the machine user from direct contact with the cutting head and from debris and coolant thrown out by the machine. It is vital that all guards used in a workshop, comply with Health and Safety Law and expected standards. |

| |

MODEL ENGINEER PRECISION VERTICAL MILLING MACHINE

(Adjustable guards in position) |

| |

|

| |

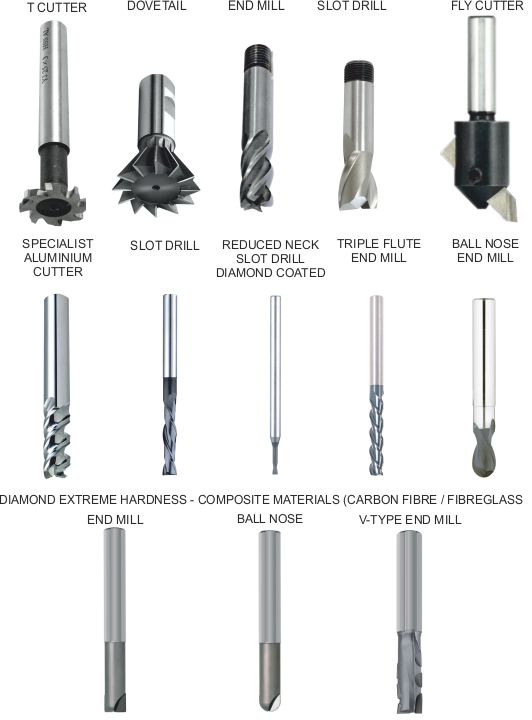

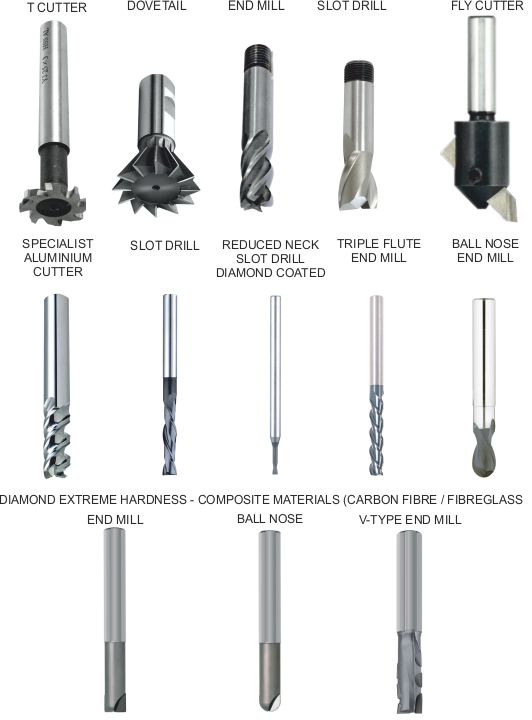

| VERTICAL MILLER CUTTERS |

| |

| A variety of cutters are available for the miller, including end mills and fly cutters. A basic range is shown below. Specialist cutters are also available. These include cutters designed for cutting and shaping composite materials or even fibreglass. |

| |

|

| |

|

|

| |

VERTICAL MILLING MACHINE - WITH TILTED MACHINE HEAD

(Adjustable guards removed for ease of viewing) |

| |

|

| |

| PDF FILE - CLICK HERE FOR A POSTER - ENGINEERS MODEL PRECISION VERTICAL MILLING MACHINE |

| |

|

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|