V.Ryan © 2021

These files only cut on the forward stroke.

| CLICK HERE FOR INDEX PAGE |

| NEEDLE FILES |

V.Ryan © 2021 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

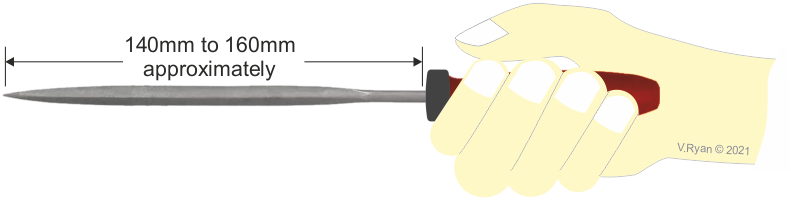

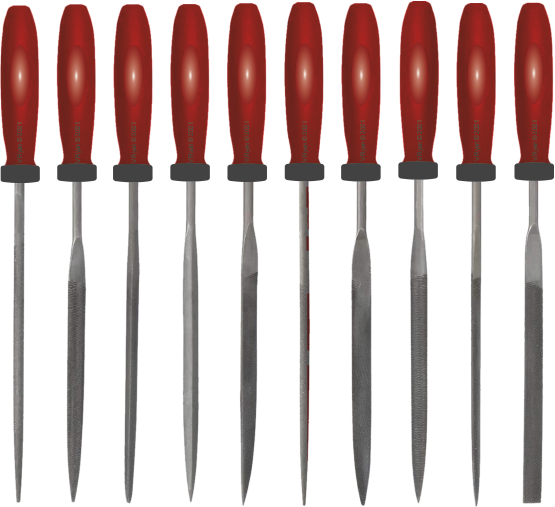

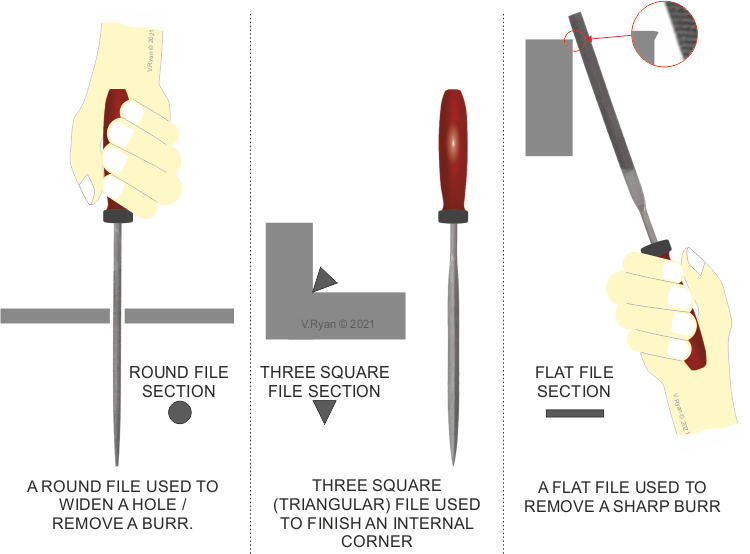

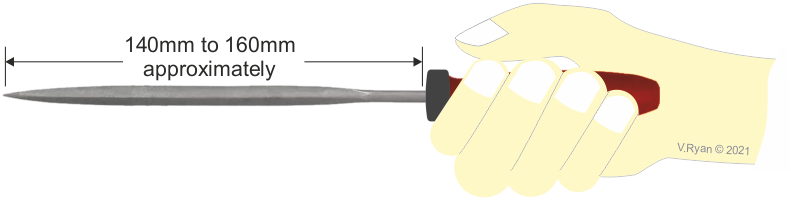

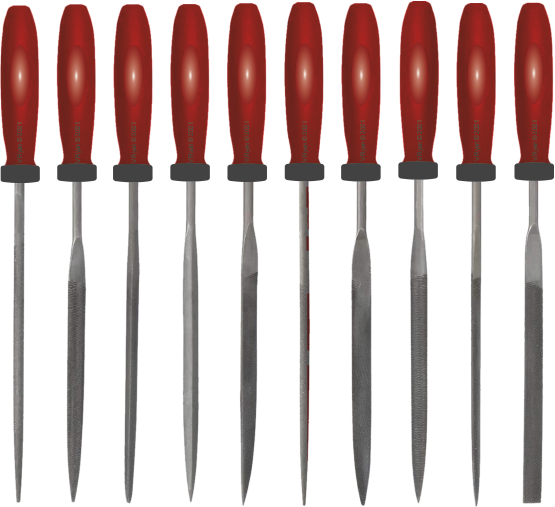

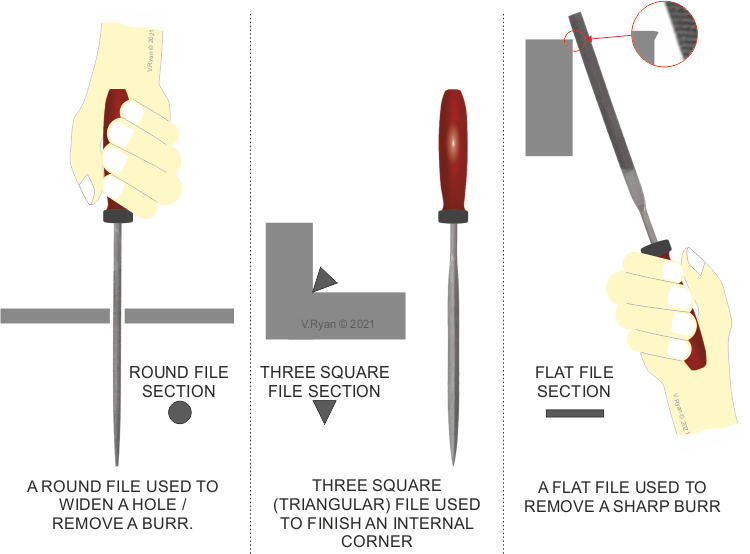

| Below is a high carbon steel (hardened and tempered) needle file set. The set includes a variety of sections such as, Round, Half Round, Barrette, Pillar (Flat), Warding, Knife, Crossing, Square, Oval, Slitting, Crochet and Three Square (Triangle). Needle files are very useful for accurate and intricate work, as well as for finishing surfaces. Each of the various sections have a purpose. They are often used for working in tight spaces / angles, such as internal corners. A round needle file is often used to enlarge holes. |

|

| Traditional needle files cut on the forward stroke, in the same way as full sized hand files. They should be stored carefully, so that they do not rub against each other, as this will shorten their life span and effectiveness. Needle files can be cleaned with a tooth brush, which removes debris caught between the teeth. Needle files are supplied in a variety of grades, from very fine to coarse. They can be broken easily, as they are thin and brittle in nature. |

|

| THREE COMMON USES OF NEEDLE FILES |

|

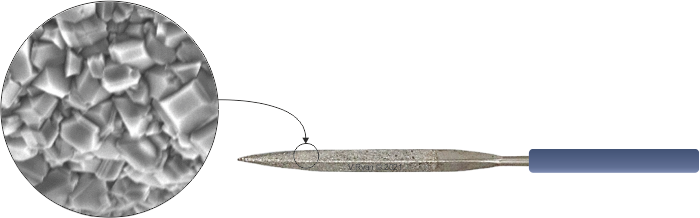

| Below is a magnified view of the surface pattern / teeth, of a traditional needle file. This shows the teeth arranged in a regular pattern. These files only cut on the forward stroke. |

|

| DIAMOND COATED NEEDLE FILES |

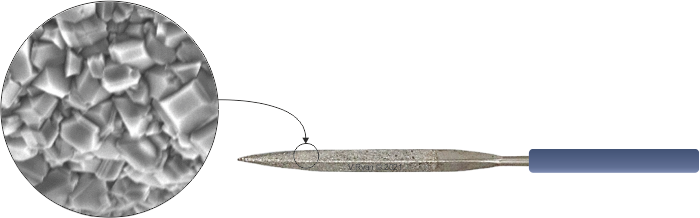

| Diamond coated needle files, are more expensive than traditional carbon steel files. They are graded from fine to coarse. This is referred to as the ‘grit’ (600 grit is regarded as fine compared to 200 grit, which is regarded as coarse). These files are used by specialists, such as toolmakers, gunsmiths, jewellers and engineers. The files are usually manufactured from tungsten carbide, which is able to withstand the high temperatures, required for the diamond coating process. Diamond coating produces an extremely hard and wear resistant file surface and is superior to the surface of traditional needle files. They can cut / file in all directions, due to the nature of the diamond coating, unlike high carbon steel files, which cut on the forward stroke only. |

| The magnified view below, of the diamond coating, clearly shows the surface texture. This provides effective cutting / filing properties, when the file is used in any direction. |

|

| SET OF DIAMOND COATED NEEDLE FILES |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|