| CLICK HERE FOR INDEX PAGE |

| |

| INTRODUCTION TO PLASMA CUTTING |

V.Ryan © 2020 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

Metals and alloys that conduct electricity, can be cut and shaped using a Plasma Cutter. This process is particularly useful, when cutting stainless steel accurately. Other metals, such as aluminium, copper, brass, cast iron and mild steel, can also be cut with this process.

One advantage of cutting and shaping using a plasma cutter, is that the metal is less likely to distort, as the heat that is generated, is localised to the cutting area. However, a potential disadvantage is that the edge left after cutting, is not as ‘clean’ / ‘smooth’, as more expensive processes, such as laser cutting and water jet cutting. Plasma cutting is cost effective. |

| |

| Plasma is known as the fourth stage of matter. Matter changes according to temperature. The first stage of matter is a ‘solid’, as the temperature rises to stage two, solid becomes liquid. This is followed by stage three, as the temperature rises further and liquid becomes gas. The fourth stage is plasma, as electrons break away from the molecular structure of the gases, at the top of the temperature range, creating intense heat of up to 22000 degrees centigrade. This heat is utilised during the cutting process. |

| |

|

|

| |

| Plasma cutting begins with a compressed mixture of gas, usually argon and hydrogen (although mixtures of hydrogen and nitrogen or methane and nitrogen, are sometimes used). The gas is focussed into a narrow path, which carries an electrical current. The electrical current forms between the electrode in the gas nozzle and a grounding clamp on the metal being cut. The electrical current ionises the gas (ionised gas is called plasma). It is this heated ionised plasma, that melts the metal in its path, cutting through. |

| |

| Plasma cutters can be hand-held, mobile units, or they can be large and requiring computer control. |

| |

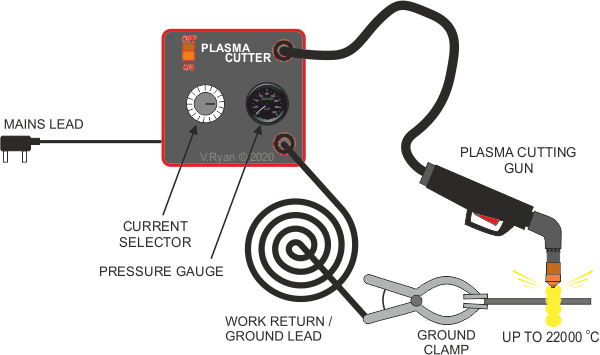

| TYPICAL SMALL SCALE MOBILE PLASMA CUTTER |

| |

|

| |

| Plasma cutters are ideal for workshops, auto-repair shops and steel fabricators, as well as large scale CNC production facilities. For smaller workshops, they provide a cost effective alternative, to other forms of cutting and shaping metals. They are quick and cut accurately through resistant materials such as steel. |

| |

|

|

| |

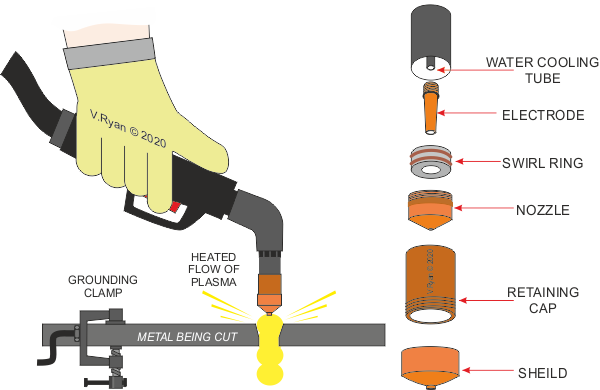

| A SMALLER MOBILE PLASMA CUTTING UNIT - SIMPLIFIED DIAGRAM |

| |

|

| |

| The internal components of the plasma gun can be seen below. The electrode is clearly identified, located inside the nozzle. The swirling ring is designed to mix the gases, that form the heated plasma. The shield protects the delicate internal components of the nozzle, against the intense localised heat, generated during the cutting process. |

| |

|

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT INDEX PAGE |

| |

|

| |

|