| CLICK HERE FOR INDEX PAGE |

| |

| PLASTIC MEMORY |

V.Ryan © 2022 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

| When a thermoplastic is heated until it becomes pliable / flexible, it can be moulded into another shape. When the same thermoplastic is heated again, it will return to its original shape / form. This is called ‘plastic memory’. This is a very useful physical property. |

| |

| EXAMPLE |

| |

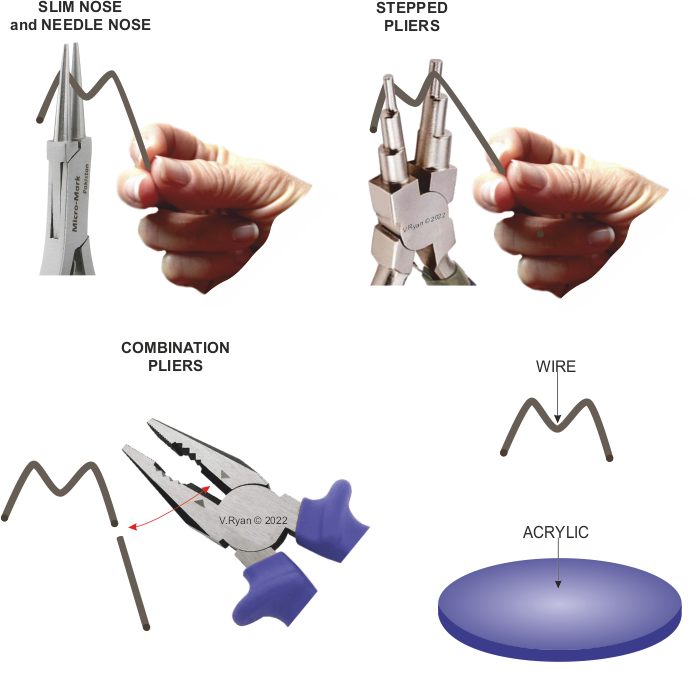

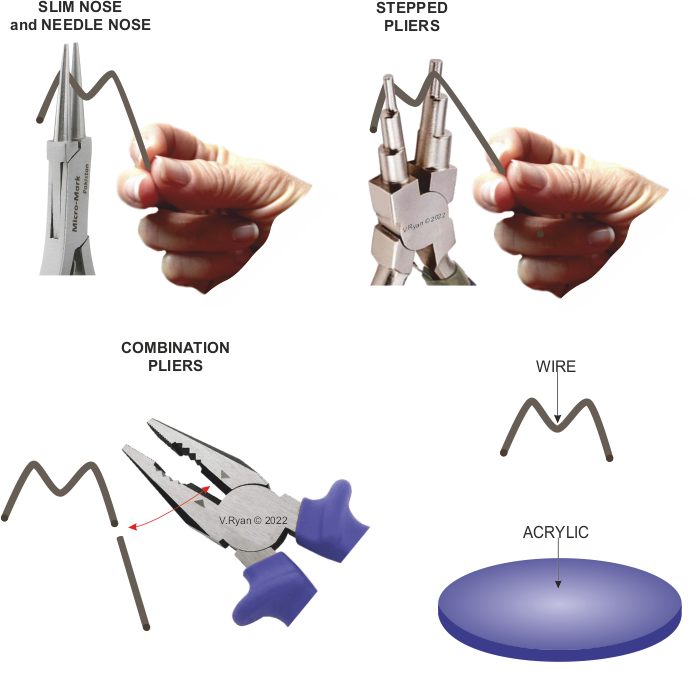

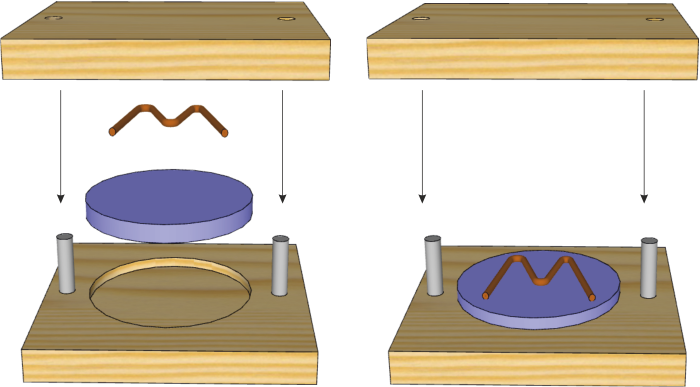

Steel / copper wire can be formed using a pair of pliers (slim nose pliers or stepped pliers).Steel welding rod is ideal for this process. The example below, shows the letter ‘M’ being formed with pliers. Excess wire is cut away with combination pliers or wire cutting pliers. Remove any rough / sharp edges, with a piece of abrasive, such as emery cloth.

A piece of 6mm acrylic is cut into a circle and the edges smoothed. This is the material being used to demonstrated ‘plastic memory’. |

| |

|

| |

|

|

| |

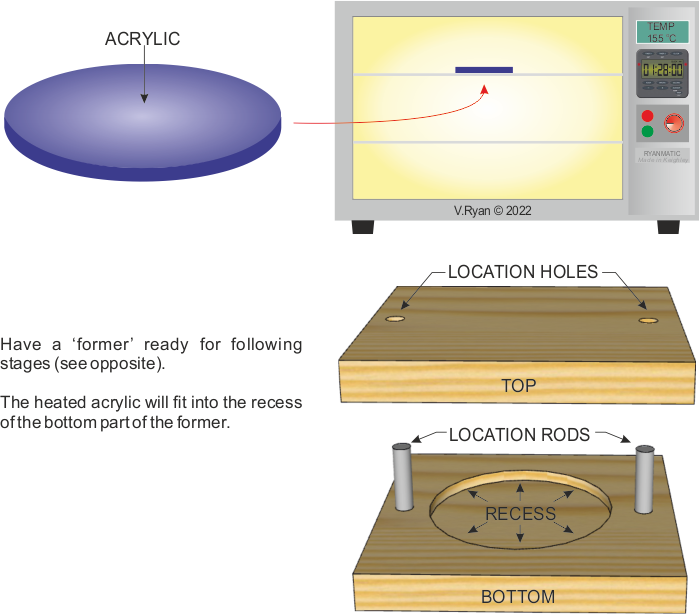

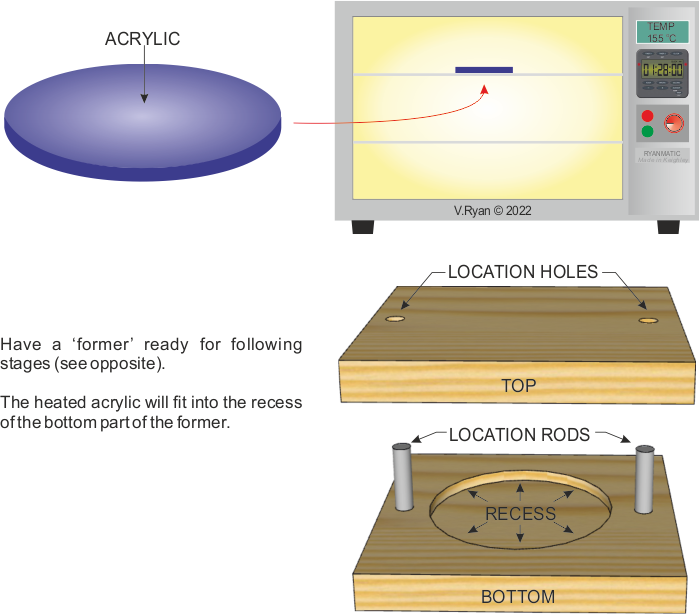

| STAGE ONE: HEAT THE ACRYLIC IN AN OVEN UNTIL IT BECOMES PLIABLE. |

| |

|

| |

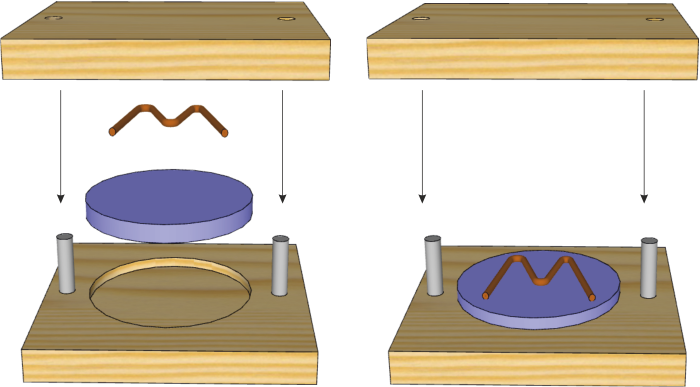

| STAGE TWO: THE ACRYLIC IS PLACED IN THE RECESS AND THE WIRE PLACED ON TOP. |

| |

|

| |

|

|

| |

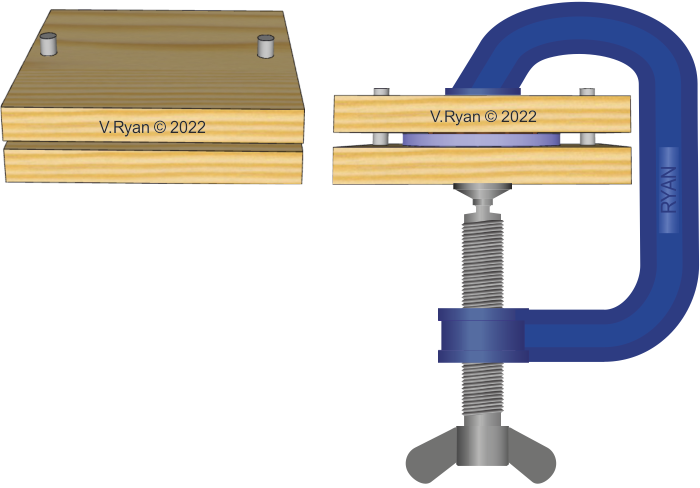

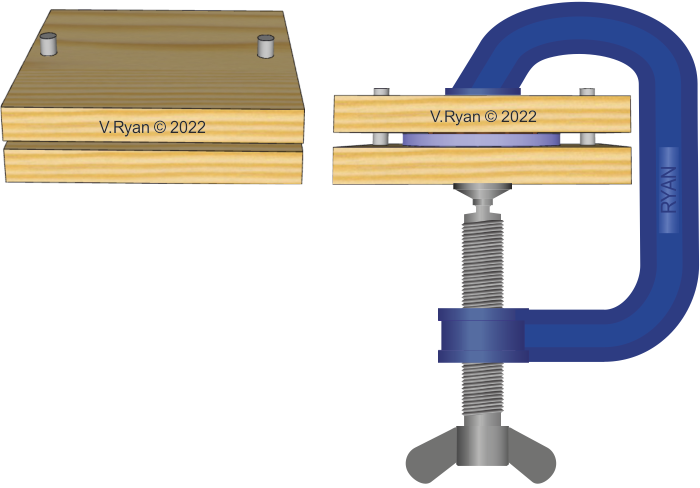

| STAGE THREE: THE TOP PART OF FORMER IS LINED UP WITH THE LOCATION HOLES AND PUSHED DOWN, PRESSING THE WIRE INTO THE ACRYLIC. A CLAMP IS NEEDED TO APPLY PRESSURE. |

| |

|

| |

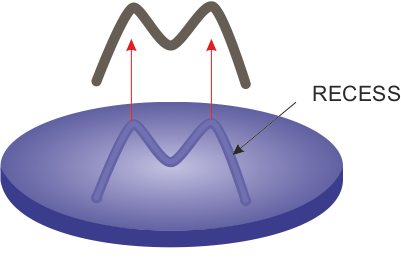

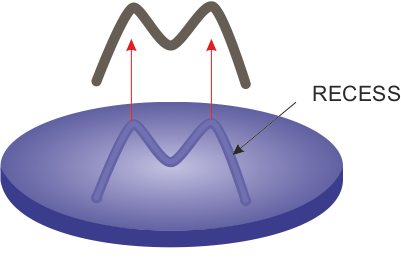

| STAGE FOUR: WHEN COOL - REMOVE THE ACRYLIC FROM THE FORMER AND REMOVE THE WIRE. A RECESS IN THE ACRYLIC, MADE BY THE WIRE WILL BE SEEN. |

| |

|

| |

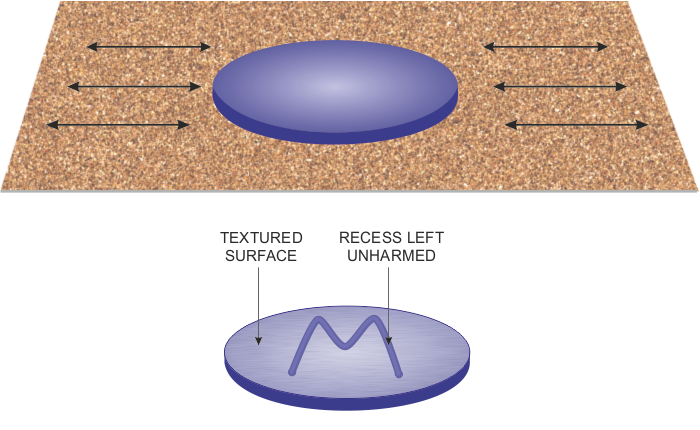

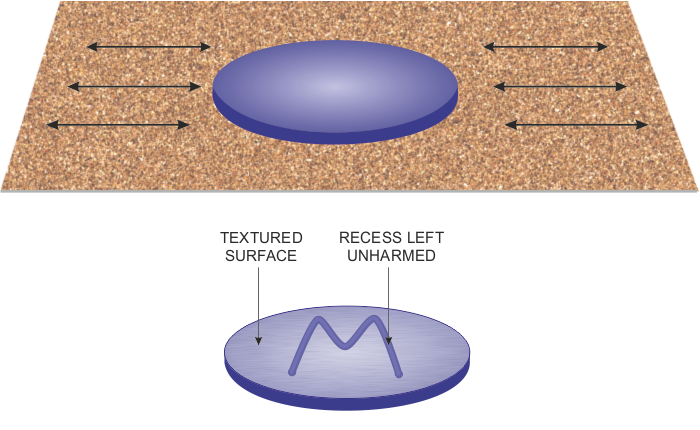

STAGE FIVE: FLIP OVER THE ACRYLIC, SO THAT THE RECESS MADE BY THE WIRE IS FACING DOWNWARDS. PLACE IT ON A SHEET OF ABRASIVE PAPER / GLASSPAPER AND MOVE BACKWARDS AND FORWARDS, REDUCING THE THICKNESS OF THE ACRYLIC A LITTLE.

THIS REMOVES SOME OF THE ‘FLAT SURFACE’ WITHOUT TOUCHING THE RECESS. IT PRODUCES A TEXTURED SURFACE ON THE FLAT ACRYLIC.

FLIP THE ACRYLIC BACK ROUND TO VIEW THE TEXTURE. |

| |

|

| |

|

|

| |

| STAGE 6: PLACE THE ACRYLIC BACK IN THE OVEN AND WATCH THE RECESSED SURFACE RETURN / RISE TO ITS ORIGINAL HEIGHT, LEAVING THE TEXTURED SURFACE BELOW IT. |

| |

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|