| CLICK HERE FOR INDEX PAGE |

| |

| HOW A PLANE BLADE IS SHARPENED |

V.Ryan © 2021 |

| |

| |

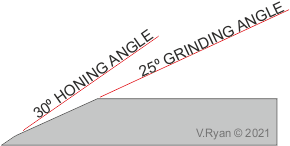

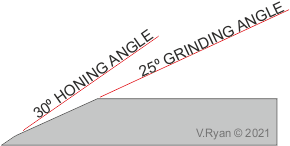

A new plane blade is ground by the manufacturer, to a 25 degree angle. An old blade may need re-grinding from time to time, on a Sharpedge or Whetstone.

A Sharpedge has a large grinding wheel, that rotates on a horizontal axis. The blade is clamped in the holder (also called the Master Arm) which is set at 25 degrees. As grinding wheel rotates, it is supplied with honing oil, which reduces the heat produced whilst grinding, preventing over heating of the blade. Grinding with a ‘Sharpedge’, is the first stage of sharpening a plane blade and other cutting tools such as chisels. |

|

| |

|

| |

|

|

| |

| The second stage of sharpening, is to place the blade flat on the oil stone (see below). Moving it along the surface, removes the ‘wired / serrated edge’, produced by the grinding process. Oil is applied to the surface of the stone, making it easier to move the blade backwards and forwards. |

| |

|

| |

|

|

| |

| The third stage of sharpening, producing the honing angle, is completed by hand using an oil stone. The ‘honing angle’ produces the final, sharp cutting edge. For a smoothing plane blade, the honing angle is normally 30-35 degrees. A ‘honing guide’ can be used to hold the blade at the correct angle, as it is moved backwards and forwards, along the surface of the oil stone. Oil is applied to the top surface of the oil stone, providing a ‘lubricated’ surface. The oil also prevents the pores of the stone, becoming ‘clogged up’, with fine practicals of metal. |

| |

|

| |

A plane blade can be ‘honed’ without the aid of a ‘honing guide’, although this requires more skill and practice.

The blade is first placed with the ‘ground angle’ flat on the oil stone, at a 25 degree angle. The angle is increased slightly to 30 degrees and the blade is moved backwards and forwards, producing the honed cutting edge. The blade must be held at the 30 degree angle, for the entire sharpening process. |

| |

|

| |

| The blade is now ready for the smoothing plane. |

| |

|

|

| |

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE |

| |

|

| |

|