| CLICK HERE FOR INDEX PAGE |

| |

| OPEN ENDED SPANNER / WRENCH |

V.Ryan © 2024 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

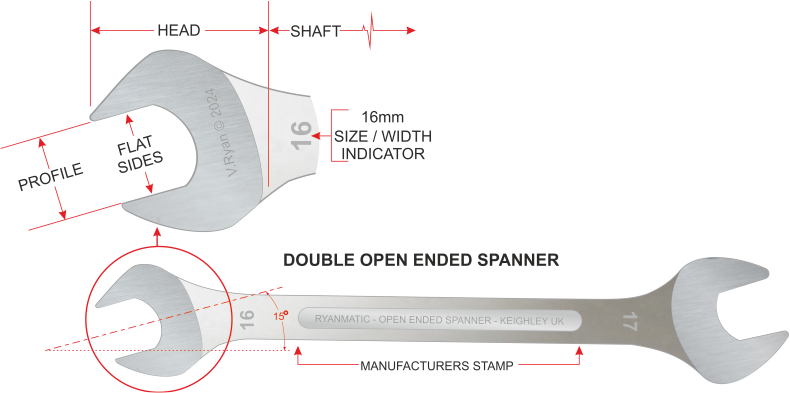

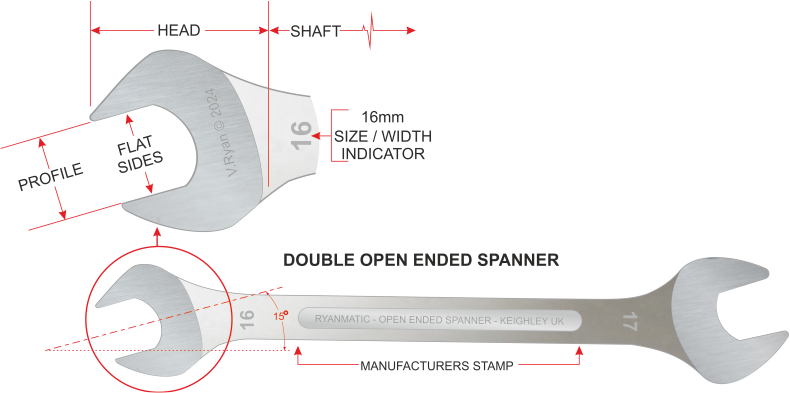

An open ended spanner, sometimes called a wrench, has a head with an ‘open profile’, normally at each end. Each of the profiles are different sizes and have flat, parallel sides.

The head is normally angled at 15 degrees, which makes the rotation of the spanner easier. The spanner shown here is a double open ended spanner. Single open ended spanners are also available.

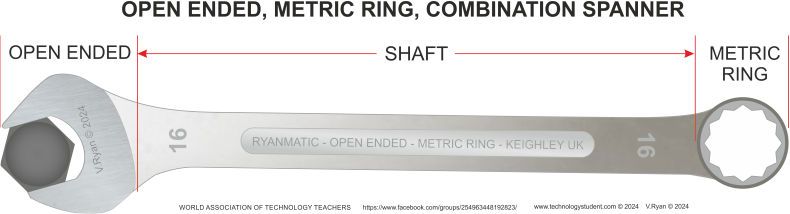

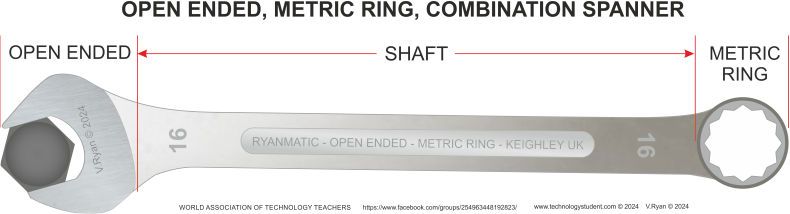

The second spanner is a combination spanner with a metric ring and open ended heads |

| |

|

| |

|

| |

|

|

| |

| TYPICAL SET OF OPEN ENDED SPANNERS |

| |

|

| |

Open ended spanners have a ‘flat’ head, allowing access to narrow spaces. They have two faces that grip the bolt / nut.

The head of a ring spanner fits tightly around the head of a bolt / nut. Due to the way a ring spanner grips / encloses the head of a bolt, more force can be applied and it is less likely to slip.

Both types of spanner are supplied in sets of a variety of sizes.

A combination spanner has an advantage of one end being open and other being a ring. Both ends are the same size. |

| |

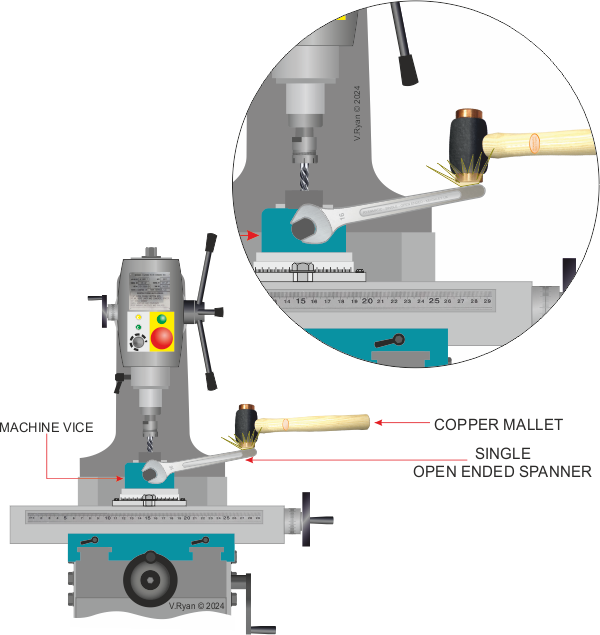

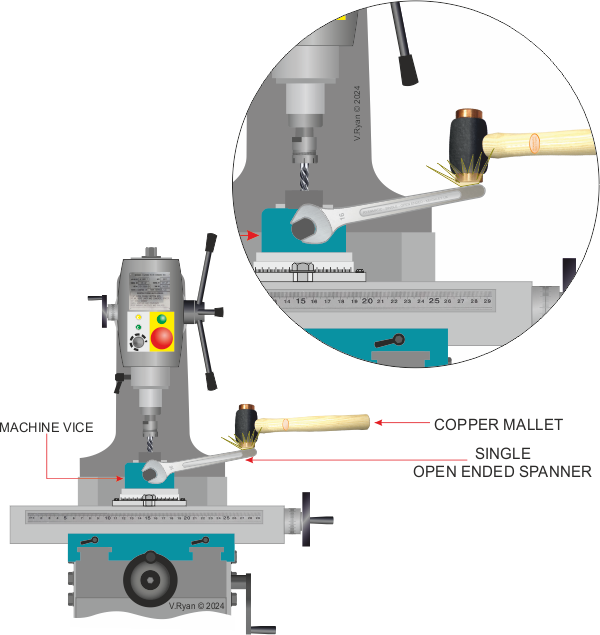

| A single open ended spanner has one ‘head’ and a shaft that narrows towards the end. This type of spanner is ideal for tightening larger machine vices, such as those supplied with milling machines. |

| |

|

| |

|

|

| |

TYPICAL USE OF A SINGLE OPEN ENDED SPANNER

Tightening and loosening the grip of a heavy duty machine vice, on the table of a vertical milling machine.

Note the use of a copper / hide mallet, which allows force to be applied without damaging the vice. |

| |

|

| |

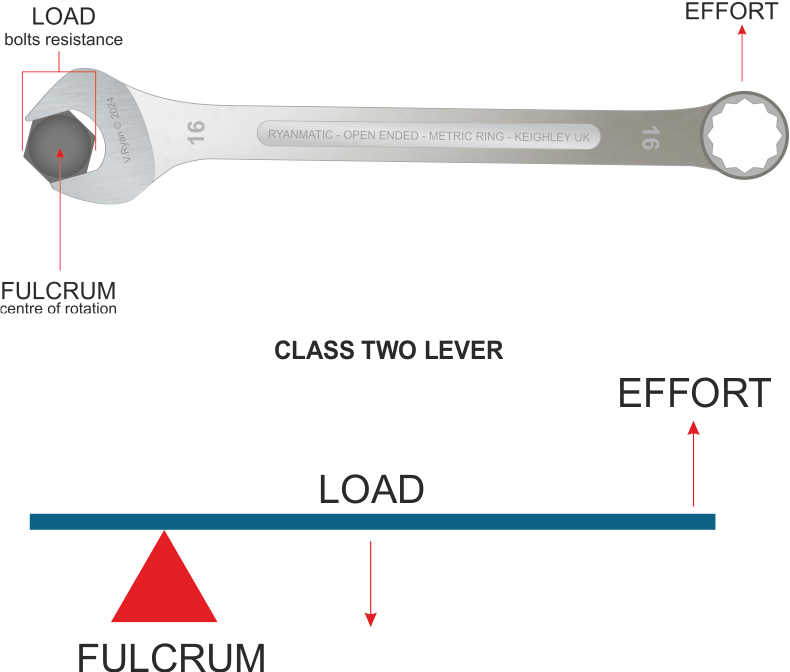

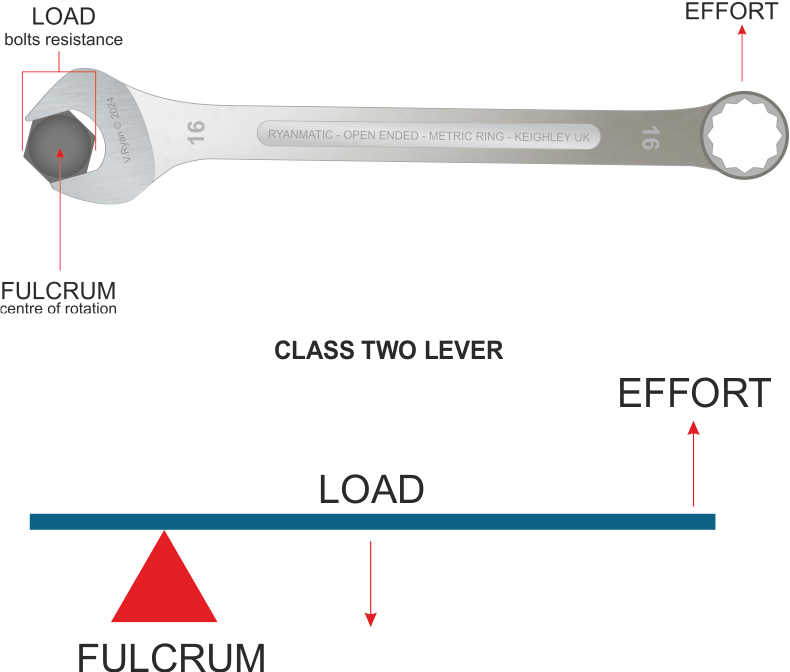

| Open ended spanners and combination spanners are excellent examples of a class two levers, as seen below. |

| |

| A spanner is a class two lever when used to tighten / loosen a bolt / nut. The position of the head, surrounding the bolt / nut is the ‘fulcrum’. The resistance against turning is the ‘load’ and the force required to move the handle is the ‘effort’. The longer to lever, the easier it is to turn the bolt. This is called mechanical advantage. |

| |

|

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|