| CLICK HERE FOR INDEX PAGE |

| |

| ENGINEERS SPRING DIVIDERS |

| V.Ryan © 2019-2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

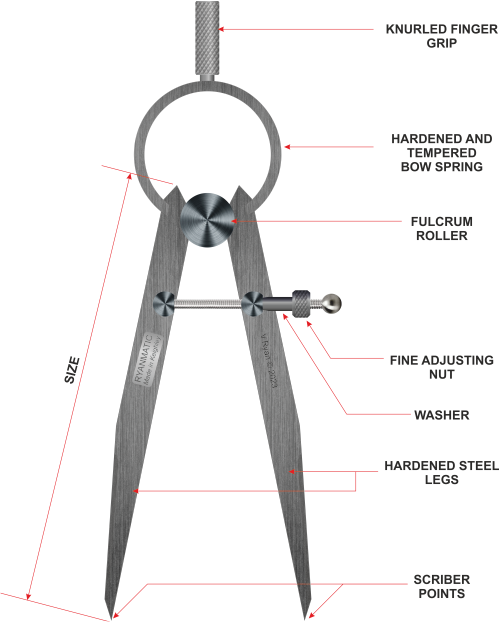

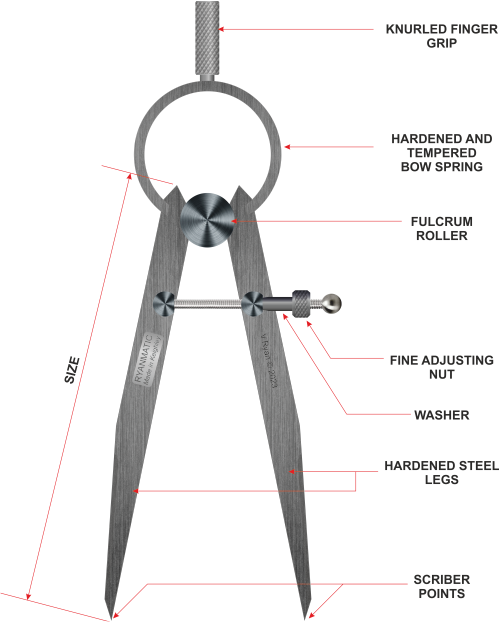

Spring dividers are a general marking out tool, for arcs, circles and radii. This tool used for accurate marking and has a fine adjusting nut to ensure precise measuring / marking out. The adjusting nut firmly holds the scriber point at a set distance.

Spring dividers are supplied in a range of sizes, with the size being determined by the length of the leg. They should be oiled occasionally, to prevent corrosion and to ensure smooth movement of the adjusting nut. |

| |

|

| |

| |

|

|

| |

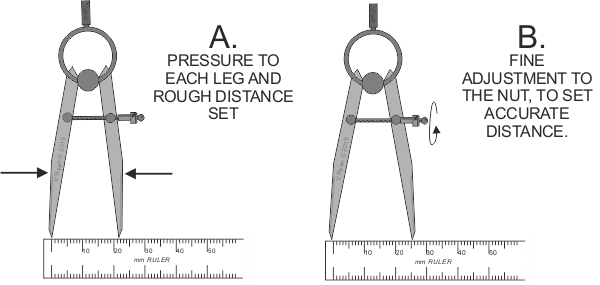

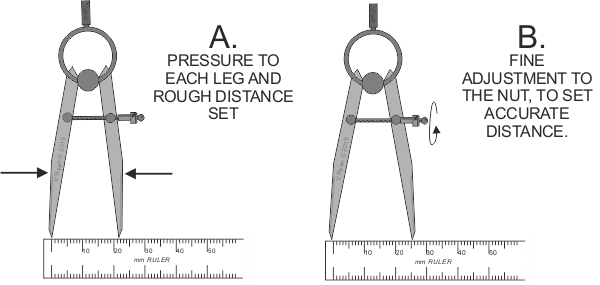

| The procedure for setting the distance between each leg, is straightforward. Pressure is exerted to each leg by the user’s hand, reducing strain on the adjusting nut. The legs are set ‘roughly’ to the required distance and then, the adjusting nut is gently tightened, holding the legs in position. Fine adjustment is then made to the adjusting nut, until the exact distance is set. The knurled finger grip, allows the user to ‘walk’ the dividers along a marked / scribed line, measuring distances. |

| |

|

| |

|

|

| |

| The point of rotation of the spring dividers, is punched with a ‘centre punch’, ensuring that the scriber point does not slip out of position. The dividers are then rotated, scribing the arc / circle. This should be done lightly at first and then with a little more weight. Sometimes rotating the sheet metal, whilst holding the dividers in position, works really well. |

|

|

| |

|

|

| |

|

|

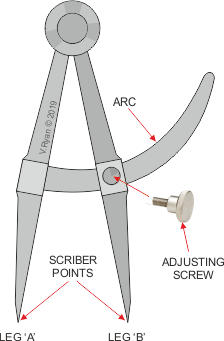

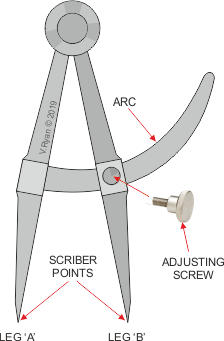

This is a more traditional and robust engineers dividers.

Leg ‘A’ includes an ‘arc’. The adjusting screw on leg ‘B’ is loosened, allowing the distance between the scriber points of B and A to be altered and then fixed by tightening the adjusting screw.

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|