| CLICK HERE FOR INDEX PAGE |

| EXTRUSION BLOW MOULDING (QUESTION) |

| V. Ryan © 2012 - 2016 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| VIDEO OF EXTRUSION BLOW MOULDING |

|

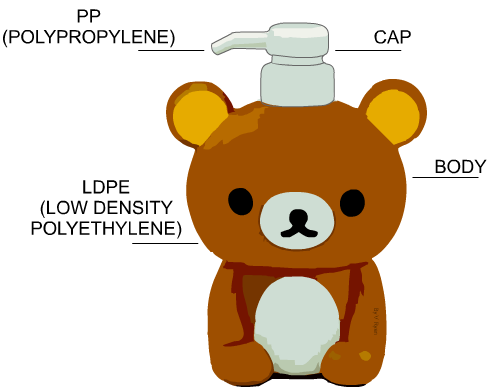

Using notes and diagrams, describe the way the LDPE soap dispenser bottle (seen below) is manufactured, through the process called extrusion blow moulding. |

|

| NOTES: |

| DIAGRAMS: |

| SAMPLE ANSWER |

| NOTES: |

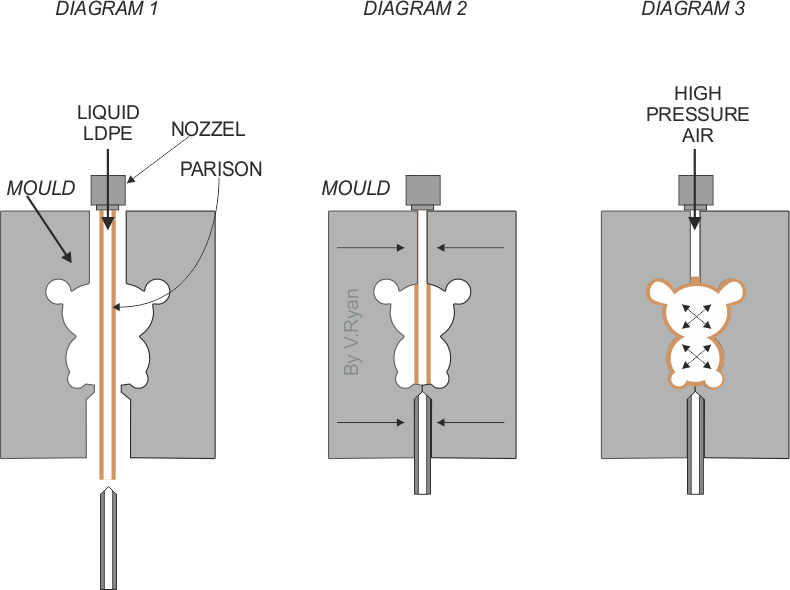

| The extrusion blow moulding process (EBM), is very

similar to blow moulding. The only difference is at the mould. LDPE granules are heated and made into a molten state. DIAGRAM. 1. The liquid is extruded through a nozzle in the form of a tube called a 'Parison'. DIAGRAM. 2 .The two halves of the mould close on the 'Parison' and shut tight. DIAGRAM. 3. Compressed air is blown into the Parison forcing the LDPE to the sides of the mould, where it cools. The moulds open, releasing the product. |

| DIAGRAMS: |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |