| CLICK HERE FOR INDEX PAGE |

| FIBREGLASS / GLASS REINFORCED PLASTIC (GRP) |

| V. Ryan © 2010 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

|

Fibreglass is an excellent example of a relatively

modern composite material (Invented in 1938 by Russel Games). In industry

it is often referred to as Glass Reinforced Plastic (GRP). |

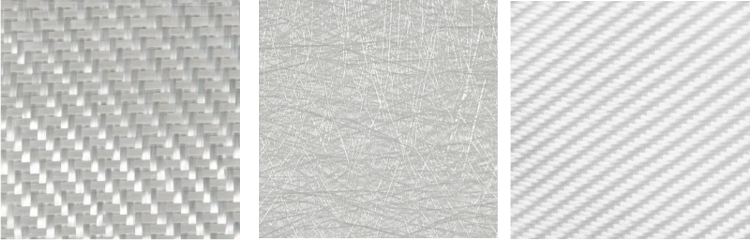

| Three samples of different weaves of fibreglass are seen below. The pattern of weave determines the strength and weight of the Glass Reinforced Plastic, after resin has been added. Different weaves have been developed for different practical applications. |

|

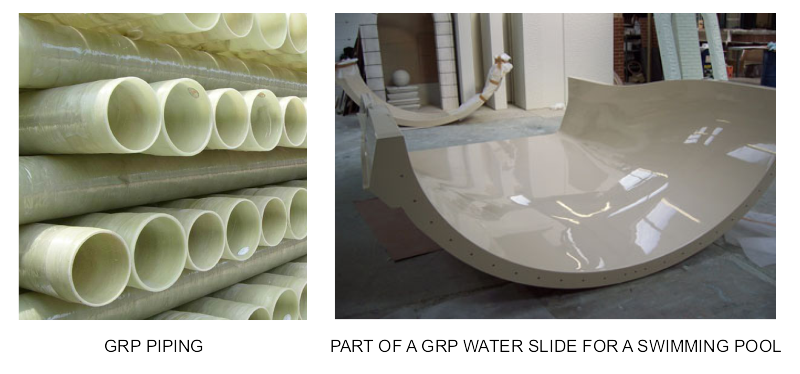

| Glass reinforced plastic is lightweight and has good thermal insulation properties. It has a high strength to weight ratio, making it useful for the production of products such as water tanks, surfboards, canoes, small boat hulls and similar products. The new European fighter plane, called ‘Eurofighter’, has an airframe which includes 12% glass reinforced plastic. |

| TWO TYPICAL USES OF GRP |

|

| Photograph courtesy of GRP Solutions - https://www.grpsolutions.com/specialist/aqua/ |

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |