| CLICK HERE FOR INDEX PAGE | ||

| REVISION CARDS - TREES TO MANUFACTURED PRODUCTS | ||

| V. Ryan © 2014 | ||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | ||

|

|

||

|

||

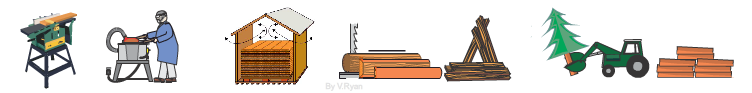

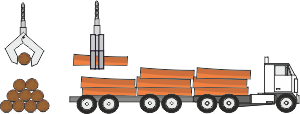

TREE FELLING The first stage of converting natural wood to a product, is felling trees. Examples of natural woods are: Pine, mahogany, oak and many more.  TRANSPORT TO SAWMILL After a short time stored in the forest, to allow ‘free water’ to evaporate, the felled trees are transported to a sawmill, for initial processing.  |

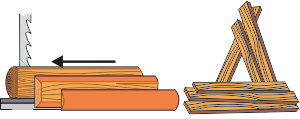

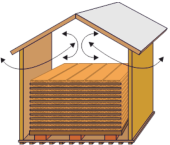

BREAKING DOWN / ROUGH SAWING IN THE SAWMILL In the sawmill, the logs are rough sawn into boards, a process called conversion.  SEASONING At this early stage, the boards contain too much water and they are allowed to dry out for several months, in seasoning sheds. A quicker way is to dry the wood in kilns  . |

|

RESAWING TO ACCURATE SIZES Once the natural wood is seasoned, it is ready for machining and manufacturing, into products such as furniture. A circular saw may be used to cut the lengths and sections to accurate sizes. The wood is then planed to produce a smooth and accurate finish.  |

NATURAL WOOD PRODUCTS |

|

| QUESTIONS | ||

| 1. Describe the main stages of ‘processing’ a tree into a product. 5 marks | ||

| 2. What is seasoning of natural wood and why is it necessary? 2 marks | ||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||