V.Ryan © 2021

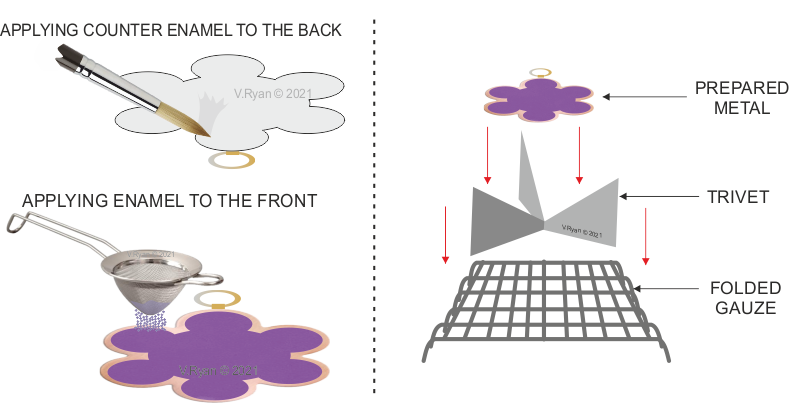

It is good practice to ‘counter enamel’, if the metal is less than 1.3mm in thickness. The procedure involves enamelling the back of the piece / metal. This helps prevent the metal warping and the enamel on the front, from cracking, as the metal deforms due to heat.

The procedure is as follows:

Apply liquid enamel (enamel powder mixed with water / holding solution / enamel adhesive) to the back, allow it to dry. Turn the piece over and rest on a trivet.

Add the first layer of enamel to the front, with a sieve and turn the piece over when it has dried.

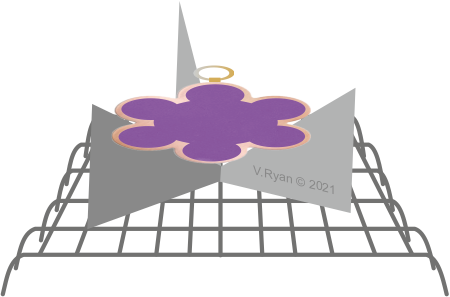

Fire the piece / metal.

Finally, add a second layer of enamel to front and fire.

Counter enamelling is easier, if the firing takes place in a kiln. The reason for this, is that the enamel placed on the back, can be fired at the same time as the enamel on the front. The use of a trivet to hold the metal, makes this procedure ideal for a kiln.