| CLICK HERE FOR INDEX PAGE |

| |

| HARD (SILVER) SOLDERING |

V.Ryan © 2021 |

| |

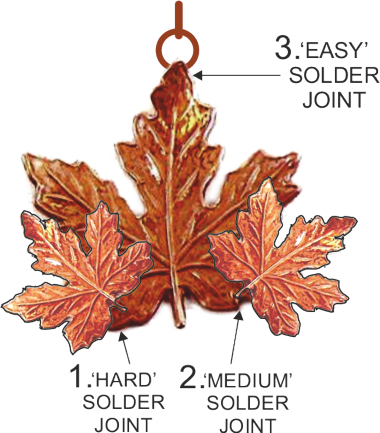

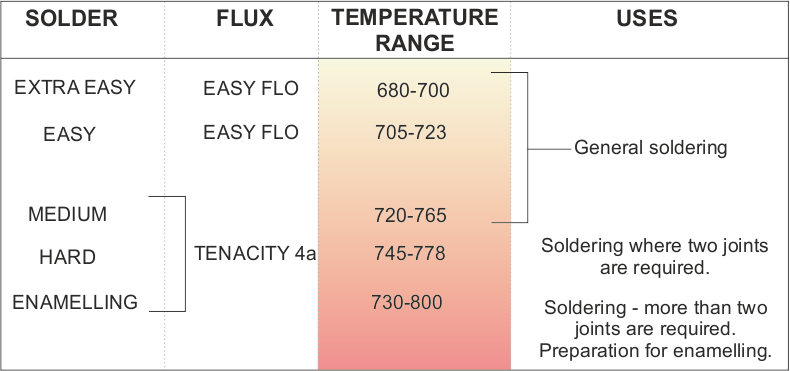

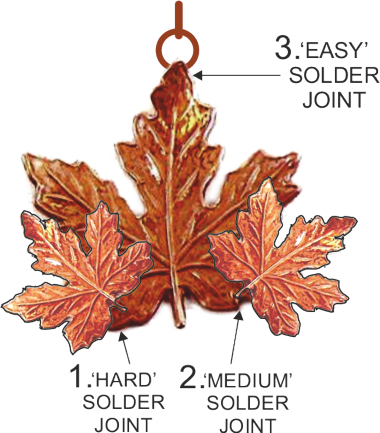

Hard soldering in terms of jewellery, is a method of permanently joining nonferrous metals, including copper, brass and nickel silver. Solder has a lower melting point, than the metals being joined. When there are a number of pieces to be joined, a higher melting point solder is used first, followed by a lower melting point solder. This ensures that the pieces being soldered, do not fall apart through the remelting of previous solder joints.

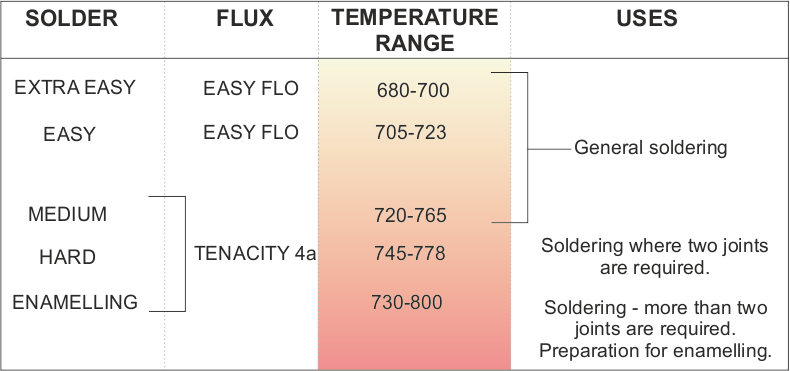

Hard soldering involves using silver solders / alloys and is sometimes referred to as ‘silver brazing’. These solders are generally copper-zinc alloys, with a proportion of silver / cadmium / nickel / phosphorous. Different hard solders have different temperature ranges and are listed below. |

| |

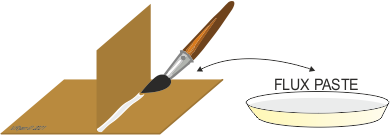

| Before soldering can take place, the surfaces of the pieces being joined must be cleaned, removing oxide, grease and general dirt . Flux is mixed with water to a paste and applied to each joint, with a soft brush. The solder is also coated with flux. The flux prevents oxidation and helps the solder to flow along the join. |

| |

|

| |

|

|

| |

| The jewellery shown opposite, is composed of four separate copper pieces. Hard solder has been used to solder one of the small leafs to the large leaf in the background. This is followed by Medium solder, which is used to solder the second small leaf to the larger one. Finally, easy solder is used to solder the ring/eye to the back of the leaf. |

|

|

| |

| Various fluxes are available, with the most popular being called ‘borax’. Nonborax fluxes are also available and they are regarded as less toxic than borax fluxes (see above). |

| |

| HARD / SILVER SOLDERING - THE PROCEDURE |

| |

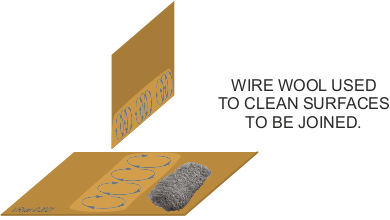

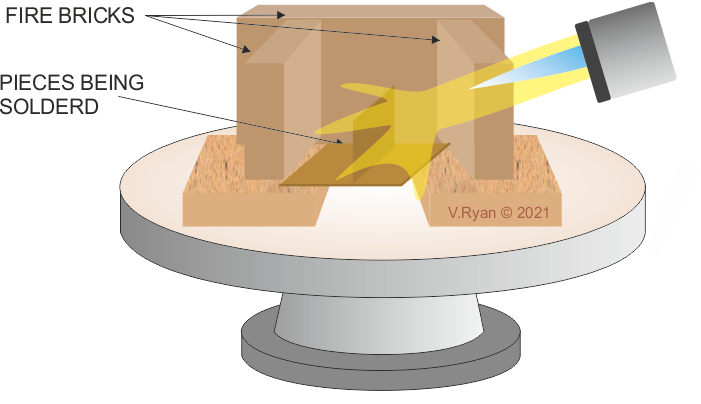

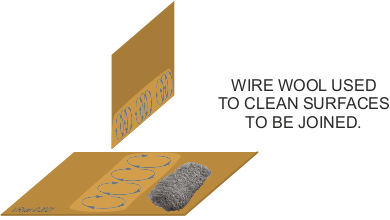

| Parts for soldering are cleaned by filing and cleaning with emery cloth or wire wool. This removes oxidation from the surfaces. |

|

|

| |

|

|

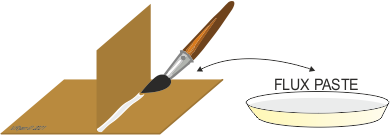

Powder flux is mixed with water, to a paste consistency. Then applied to the joint.

The flux prevents oxidation taking place during heating and dissolves any oxide, that has escaped the cleaning process. |

|

|

| |

|

|

| |

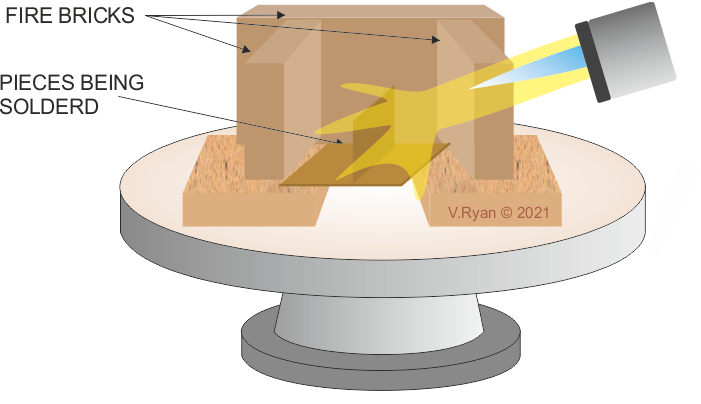

| The soldering starts with a soft flame, which is used to warm up the metal and to evaporate water from the flux. The water bubbles as it evaporates (a process called ‘flowering’). |

| |

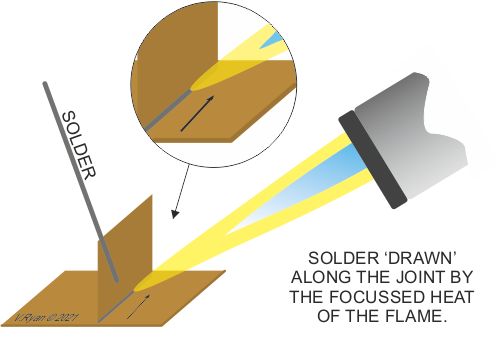

The flux will ‘blacken’, as the correct temperature is reached. Some jewellers prefer to adjust the flame to a ‘hard flame’ at this point. This allows greater accuracy when heating the area to be soldered.

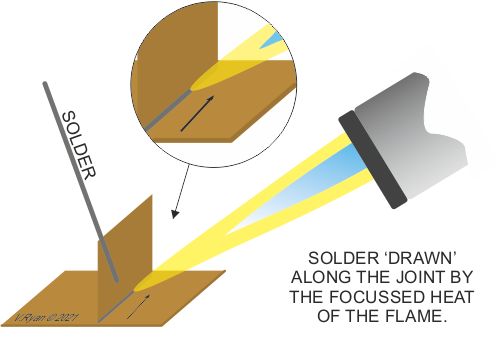

The solder is then introduced, touching the joint and it is drawn by the focussed heat of the torch and flux, along the joint line, producing a ‘silver’ line. Heating of the joint stops immediately and the work is allowed to cool and is then placed on a steel block / anvil, to cool down totally. |

| |

|

| |

|

| |

| The piece is then placed in a pickling tank, removing oxide and the residue left by the flux. |

| |

|

|

| |

| CLICK HERE FOR JEWELLERY INDEX PAGE |

| |

|

| |

|