|

The teak is measured and marked out accurately using a tape measure and a pencil. All measurements are checked carefully. Basic measurements of boards are marked out in this way. |

||

|

||

|

|

A marking knife is then used to mark individually sides. This is more accurate and allows for precise cutting. |

|

|

|

Each individual length is cut using a tenon saw. A bench hook is used to hold the work so that cutting can take place. |

|

|

|

A disk sander is used to finish the ends of the material precisely and for rounding off ends. |

|

|

|

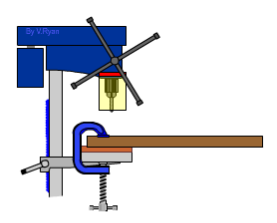

Holes for the pivots and screws are then drilled on a bench drill or pillar/machine drill. The teak is clamp securely in position. |

|

| CLICK HERE FOR NEXT STAGE OF MANUFACTURE | ||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||