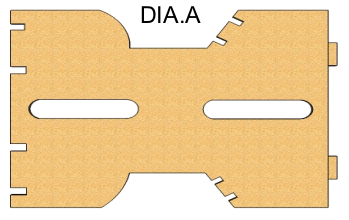

| The wood

recycling bin seen below is manufactured from MDF. The bins are

manufactured in a variety of sizes. The following stages outline the manufacture of a side of the bin ( see diagram A) through the use of a variety of machines and pieces of equipment. |

|

|

|

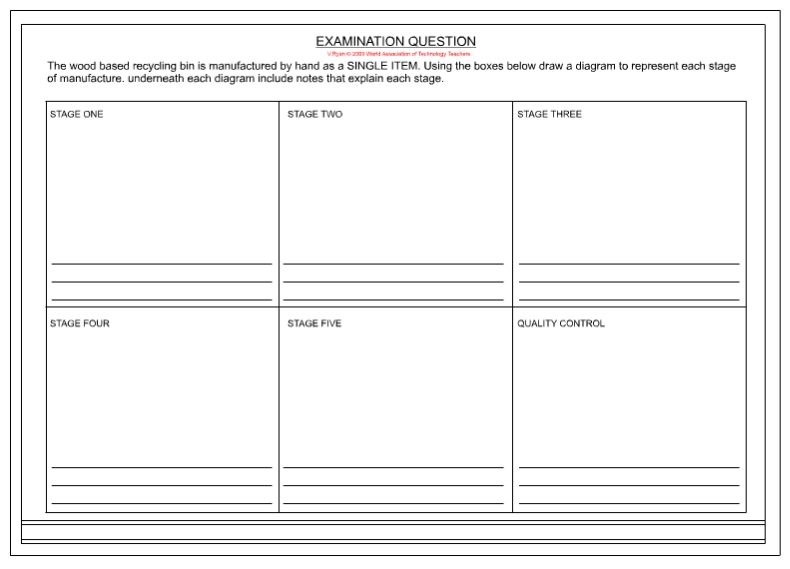

| STAGE ONE: MDF has been selected as

the material for the sides. A card template is used to draw round the

shape. The card template can be used many times to help produce a high

number of sides, depending on the number of bins being manufactured. |

|

| STAGE TWO: The shape is cut by hand using a bandsaw or fretsaw according to the size of the bin. Larger bins are cut on a bandsaw. Both the bandsaw and fretsaw allows for accurate cutting and shaping. | |

|

|

| SIDE THREE: A bevel edged chisel is

used to trim the joints and to make minor corrections. Care must be taken when using the chisel. Both hands are kept behind the cutting edge and the work is clamped to the bench. Scrap wood is placed underneath the work so that the surface of the bench is not damaged. |

|

| STAGE FOUR: A sheet sander is used to

finish the surface of the wood. This can be followed by hand finishing the surfaces with fine glass paper if a high quality finish is required. |

|

| STAGE FIVE: The side is then varnished or dyed. The most suitable varnish is called polyurethane varnish. It gives a clear protective layer. If waxed/polished the finish is extremely smooth. The varnish protects the wood from moisture in the air and small knocks and scrapes. |  |

| QUALITY CONTROL: This plays a part

during every stage of manufacture. Each stage is check by an inspector to

ensure the parts that make up the final product are accurately made,

finished properly and that the product received by the customer is in

perfect condition. For example, when the template is used to mark out the shape (stage one) the accuracy of the outline is checked visually before it is cut on the fretsaw. Quality checks are carried out at every stage of making. If this is done properly the product should be in perfect condition when it is ready for display in the shops. The drawing shows a magnifying glass is being used by an inspector to check for any defects. |

|

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| EXAMINATION QUESTION | |

|

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |