A ‘monocoque’ structure does not rely on a frame for strength / structural integrity. It relies on the outer skin / shell, to counter stresses and loads. For example, the carbon fibre reinforced bodywork, of a modern Formula One racing car, is an example of this type of structure. The bodywork is one piece and does not require internal strengthening, through the inclusion of a frame. The monocoque increases the safety of the car, as it is less likey to break apart in the event of a crash.

Monocoque structures are not a new idea. Some racing cars in the 1960s, used an aluminium monocoque, as the bodywork, which saved weight and improved fuel consumption. |

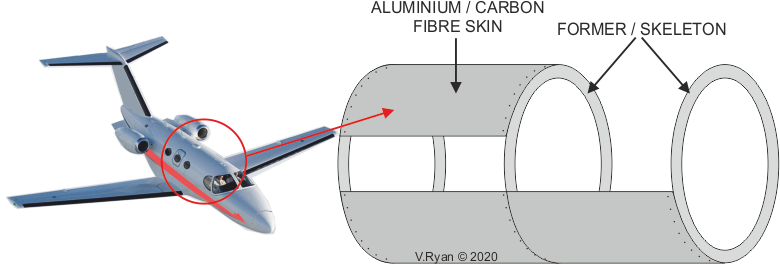

| A plane is an excellent example of this type of structure. The external aluminium ‘skin’ of the plane, provides the necessary structural strength. The first recorded use of a monocoque shell, in the manufacture of a plane manufacture, was in 1912. Modern passenger jets are referred to as monocoques, although they rely on both the skin / shell and the formers, which form a skeleton. This type of structure is more accurately referred to as a semi-monocoque. The wings of modern passenger jets are also a monocoque construction. |

| A semi monocoque structure for the fuselage of a plane has several advantages. The main being that, the combination of the ‘skeleton’ and ‘skin’, provides improved structural integrity. The combined structure is lightweight, which leads to fuel efficiency and consequently, reduced pollution, when in flight. |